For Machines Mfg. Since 3/11 Turn-Nado

®

EVS Lathes

-75-

MAINTENANCE

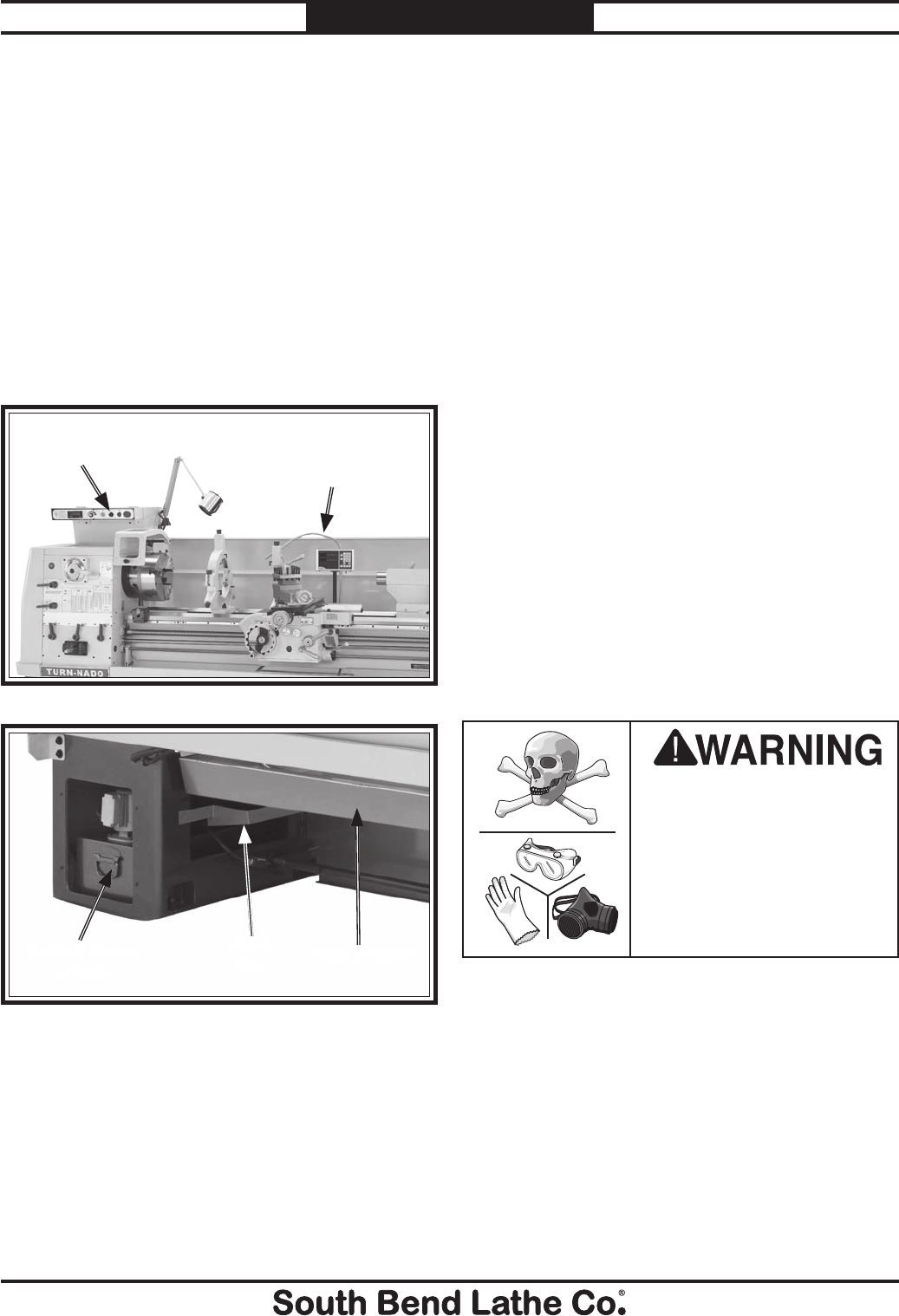

Coolant System

Service

The coolant system consists of a fluid tank,

pump, and flexible nozzle. The pump pulls fluid

from the tank and sends it to the valve, which

controls the flow of coolant to the nozzle. As the

fluid leaves the work area, it drains back into

the tank through the chip drawer and catch tray

where the swarf is screened out.

Use Figures 112–113 to identify the locations of

the coolant system controls and components.

Although most swarf from machining operations

is screened out of the coolant before it returns

to the tank, small particles will accumulate in

the bottom of the tank in the form of sludge. To

prevent this sludge from being pulled into the

pump and damaging it, the pump’s suction tube

is positioned a couple inches from the bottom

of the tank and fitted with a fine screen. This

works well when the tank is regularly cleaned;

however, if too much sludge is allowed to

accumulate before the tank is cleaned, the pump

will inevitably begin sucking it up.

Hazards

As coolants ages and gets used, dangerous

microbes can proliferate and create a biological

hazard. The risk of exposure to this hazard can

be greatly reduced by replacing the old fluid

on a monthly basis, or as indicated by the fluid

manufacturer.

The important thing to keep in mind when

working with the coolant is to minimize exposure

to your skin, eyes, and lungs by wearing the

proper PPE (Personal Protective Equipment),

such as splash-resistant safety goggles, long-

sleeve waterproof gloves, protective clothing, and

a NIOSH approved respirator.

BIOLOGICAL & POISON

HAZARD!

Use the correct personal

protection equipment when

handling coolant. Follow

federal, state, and fluid

manufacturer requirements

for proper disposal.

Coolant

Pump Switch

Nozzle

& Valve

Lever

Figure 112. Coolant controls.

Chip Drawer

Catch

Tray

Figure 113. Additional coolant components.

Coolant Pump

& Tank