DS06 User Manual ◄ 13

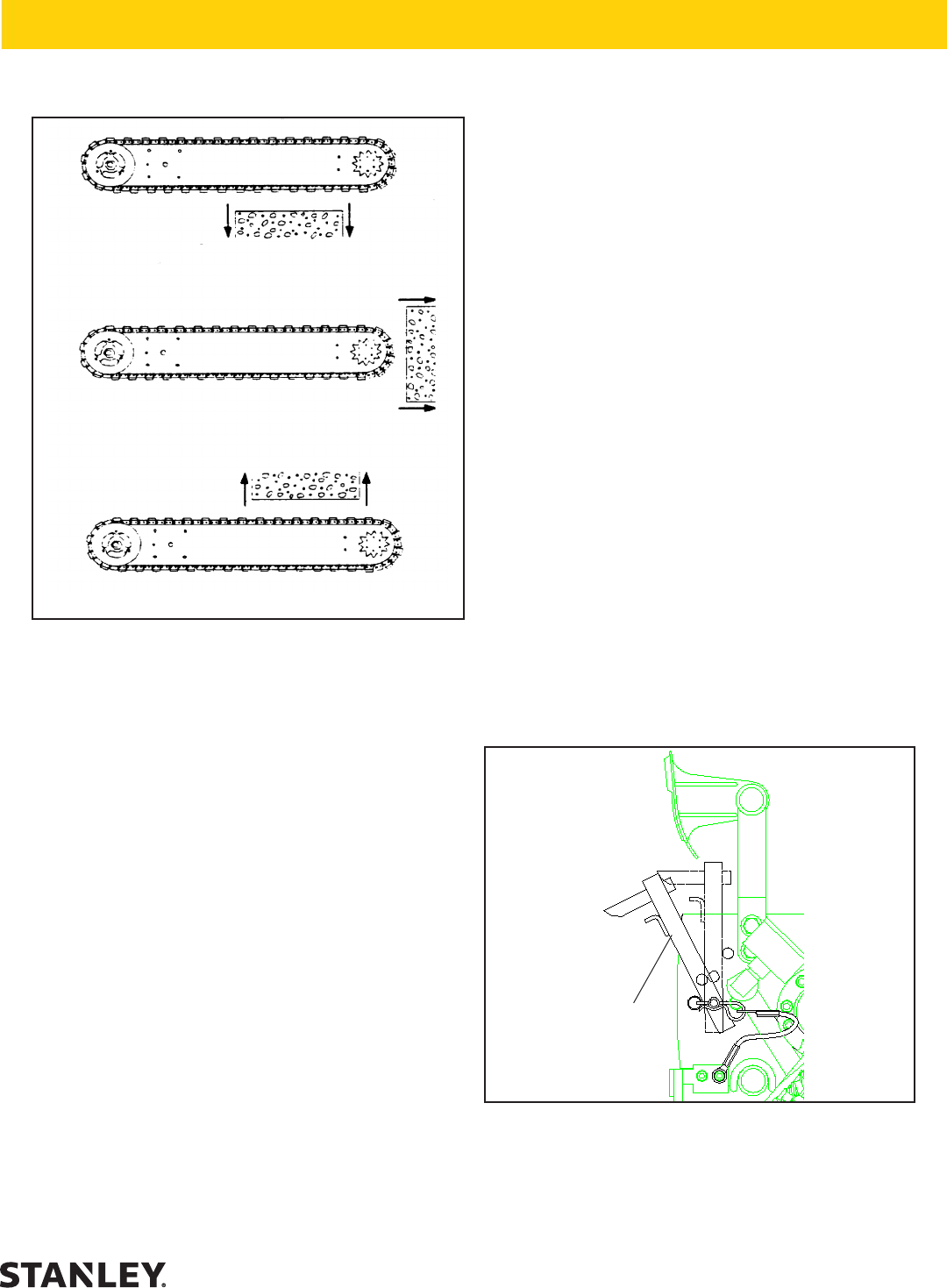

DOWN CUT

PLUNGE CUT

UP CUT

Figure 6. Types of Cuts (chain guard removed for

clarity)

1. Do not use a cutting force in excess of 45 lbs/20

kg. Excessive force causes the chain to slow down

or stall and causes premature wear of the saw bar

and chain.

2. Always maintain a high chain speed. High chain

speeds produce the best results.

3. Always check that plenty of water is being expelled

from the bar and chain. When the tool is running,

water is directed to the interior of the bar and then

out of several holes located along the top and bot-

tom channels on the bar. If these holes become

plugged, cutting debris will not be adequately

washed away and will result in premature wear of

the bar and chain.

4. Avoid aggressive/heavy plunge forces. Aggressive

plunge force creates fragmenting of the concrete

when the saw bar and chain exits and causes pre-

mature bar and chain wear.

COLD WEATHER OPERATION

If the saw is to be used during cold weather, preheat the

hydraulic uid at low power source speed. When using

the normally recommended uids, uid should be at or

above 50 °F/10 °C (400 ssu/82 centistokes) before use.

Damage to the hydraulic system or chain saw can result

from use with uid that is too viscous or thick.

USING THE WALL WALKER™

The Wall Walker™ lessens operator fatigue and effort

during cutting by automatic insertion of the wedge into

the cut, thus allowing the operator to apply leverage to

the saw.

1. Position the Wall Walker™ in the "autofeed" position

by pinning the lever arm at the lowest hole as shown

in the illustration.

Start cutting with the DS06 until the cut is large

enough to allow the tip of the wedge to insert into the

cut. With the tip of the wedge in the cut, the opera-

tor can easily apply leverage to the saw which will

aid the cutting process and lessen operator fatigue

and effort.

After the saw cuts approximately 1 to 2.5 in./25 to

65 mm, withdraw the saw only enough to allow the

lever arm and wedge to reposition. After reposition-

ing, continue cutting.

2. The Wall Walker™ can be positioned to the “parked”

position by pinning the lever arm at the upper most

hole. In this position, the Wall Walker™ is used as a

bucking cleat.

Wall Walker™ Lever Arm

(Shown in “autofeed position)

Figure 7. Wall Walker™

OPERATION