20 ► DS06 User Manual

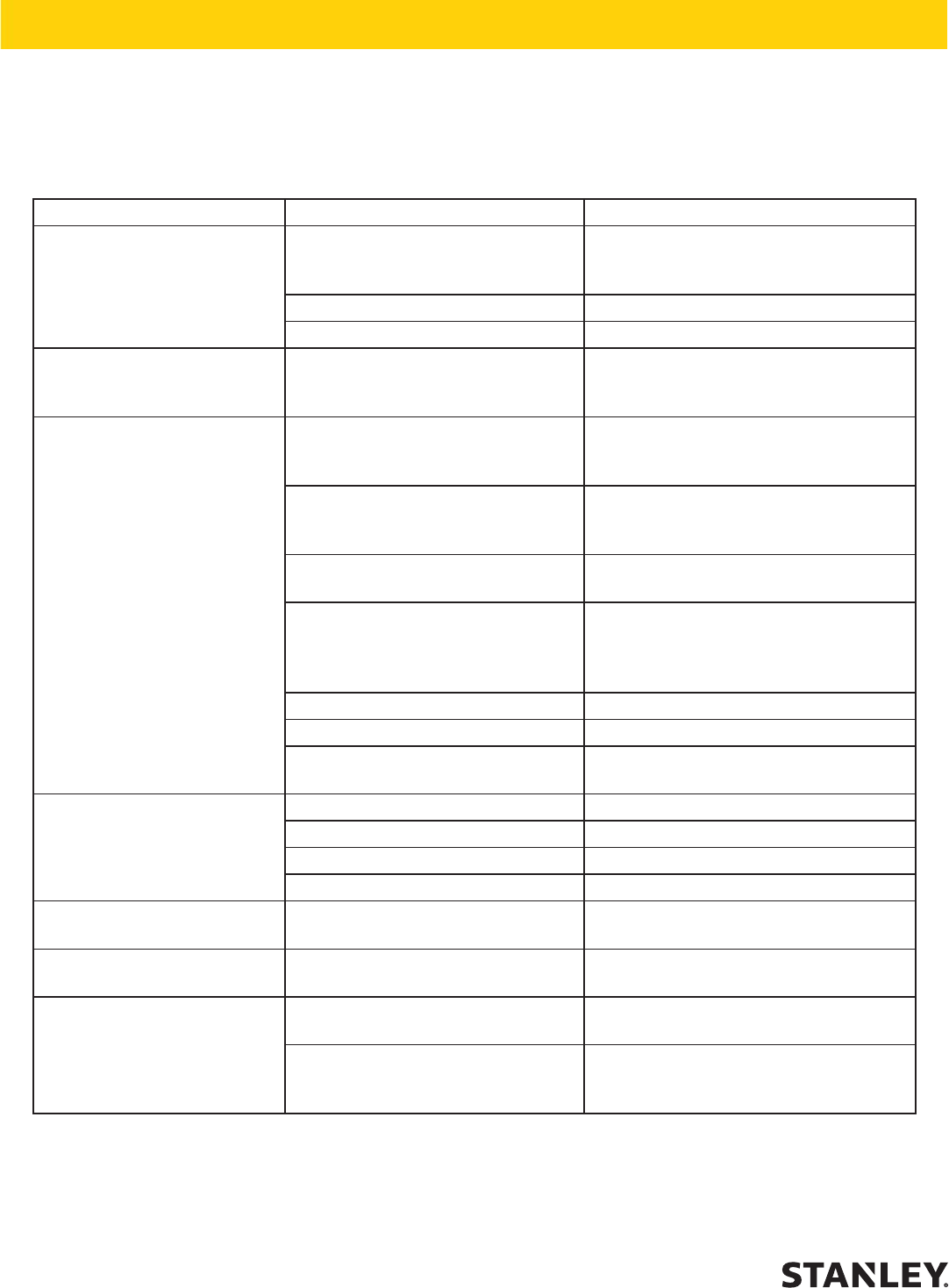

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the tool, always check that the hydraulic power source is supplying the cor-

rect hydraulic ow and pressure to the tool as listed in the table. Use a owmeter known to be accurate. Check the

ow with the hydraulic oil temperature at least 80 °F/27 °C.

SYMPTOM CAUSE SOLUTION

Tool does not run. Hydraulic power source not

functioning correctly.

Check power source for proper ow and

pressure (7–9 gpm 26–34 lpm at 2000

psi/140 bar.

Coupler or hoses blocked. Remove obstruction.

Mechanical failure. Have tool serviced by authorized dealer.

Tool runs backwards. Pressure and return lines incorrectly

connected.

Correct hose connections. Motor shaft

rotates counterclockwise as viewed from

the end of the motor shaft.

Diamond saw cuts slow. Insufcient uid ow or too high

back pressure or relief valve set too

low.

Check hydraulic supply. If hydraulic

supply is correct, have unit serviced by

authorized dealer.

Back pressure too high. Should not exceed 250 psi/17 bar at 9

gpm/34 lpm measured at the end of the

tools operating hoses.

Loss of diamond segment side

clearance.

Replace chain.

Chain segment dulled because of

continuous use in hard material or

rebar.

Redress segmented by cutting in

abrasive material (i.e. concrete, building

block, etc.). NOTE: This indicates that

the wrong chain is being used.

Wrong chain for application. Scale down to a lower numbered chain.

Wired edged bar rails. Dress rails square.

Hydraulic uid mixed in water

supply.

Have tool serviced.

Excessive vibration and cuts

rough.

Segment(s) broken or missing. Repair broken segment or replace chain.

Chain installed backwards. Correct chain direction.

Loose chain tension. Re-tension the chain.

Excessive feed force. Reduce feed force.

Will not cut straight. Accumulated saw bar wear and

uneven chain segment prole wear.

Turn the saw bar over and dress rails

square. Replace the saw bar and chain.

Loss of power. Drive sprocket slipping on

Trantorque® adapter.

Adjust and tighten Trantorque® adapter

to 17 ft lb/23 Nm.

Trigger hard to press. Pressure and return hose reversed. Connect for proper ow direction. Motor

shaft must rotate clockwise.

Back-pressure too high. Should not exceed 250 psi/17 bar @ 9

gpm/34 lpm measured at the end of the

tool’s operating hoses.

TROUBLESHOOTING