15

Installation

withstanding high temperatures

without degradation.

ƽƽ CCAAUUTTIIOONN

A defect in fixing or insulating the

condensation sensors may cause

incorrect adjustment and/or damage

to the compressor.

If the sensor cannot be mounted in

the place where the saturated gas

enters the sub-cooler, it must be

positioned on the sub-cooler side

and not on the condenser side. If the

condenser temperature cannot be

measured, it is preferable to

measure the liquid temperature

instead of the discharge

temperature.

ƽƽ CCAAUUTTIIOONN

To prevent interference, separate the

sensor cables from the power cables.

Electrical connections

performed by the installer

All wiring must comply with local

codes. Specific electrical schematics

and connection diagrams are

shipped with the unit.

ƽƽ CCAAUUTTIIOONN

To avoid corrosion and overheating

at terminal connections, use copper

conductors only. Failure to do so

may result in damage to the

equipment. Do not allow conduit to

interfere with other components,

structural members or equipment.

Control voltage (110 V) wiring in

conduit must be separate from

conduit carrying low voltage (<30 V)

wiring. To prevent control

malfunctions, do not run low voltage

wiring (<30 V) in conduit with

conductors carrying more than 30 V.

Connecting the RTUB with a remote

air-cooled condenser

The RTUB unit is shipped with a

holding nitrogen charge and a

separate oil charge. The RTCA

condenser is designed to operate

with the RTUB unit. To ensure

optimum operation and

performance, the RTUB must be

installed with the RTCA condenser. If

correctly, refer to the general

recommendations. Connect the

outside air sensor 5R3 to terminals 1

and 2 on terminal board 1. Connect

the condenser sensor 5R56-1 to

terminals 4 and 5 on terminal board

J4 on module A20-1. Connect the

condenser sensor 5R56-2 to

terminals 4 and 5 on terminal J4 on

module A20-2.

If the condenser is not an RTCA,

ambient temperature and condenser

temperature sensors must be

connected to the RTUB to monitor it.

The ambient temperature sensor

must be installed in a position which

represents most accurately the

condenser's surrounding

environment. It must not be exposed

to sunlight or precipitation. Ensure

that the sensor is not located in the

flow of recycled air from the

condenser discharge. The

condensation temperature sensors

must be installed on the refrigerant

piping at the place where it leaves

the condenser to enter the sub-

cooler. It is necessary to install a

condenser temperature sensor on

each refrigerant circuit. This sensor

must be fixed in compliance with the

method used to attach the bulb for a

thermostat expansion valve. This

sensor can be fixed outside the

piping if it is sufficiently insulated

with insulation capable of

convenient position. Plug the sensor

cable and the cable connected to the

control panel into the junction box.

The shielded cable can be cut to the

required length.

Note: To lengthen the sensor's power

cable, use 0.75 to 1.25 mm²

conductors, 600V. The cable used

between the junction box and the

control panel must either be shielded

or in a duct. If a shielded cable is

used, make sure it is not used with

other cables carrying 30 V or more.

Evaporator leaving water

temperature sensor 5R51 (standard)

Install this temperature sensor in the

evaporator's leaving water piping

system. To install it correctly, refer to

the general recommendations.

Connect this sensor to terminals

X7-1 and X7-2.

Evaporator entering water

temperature sensor 5R52 (standard)

Install this sensor in the evaporator

water piping. To install it correctly,

refer to the general

recommendations. Connect this

sensor across terminals X6-1 and

X6-2.

Condenser sensors 5R56-1, 5R56-2,

5R3 (option)

If an RTCA condenser is used with an

RTUB, the sensors required are

installed on the RTCA. To install them

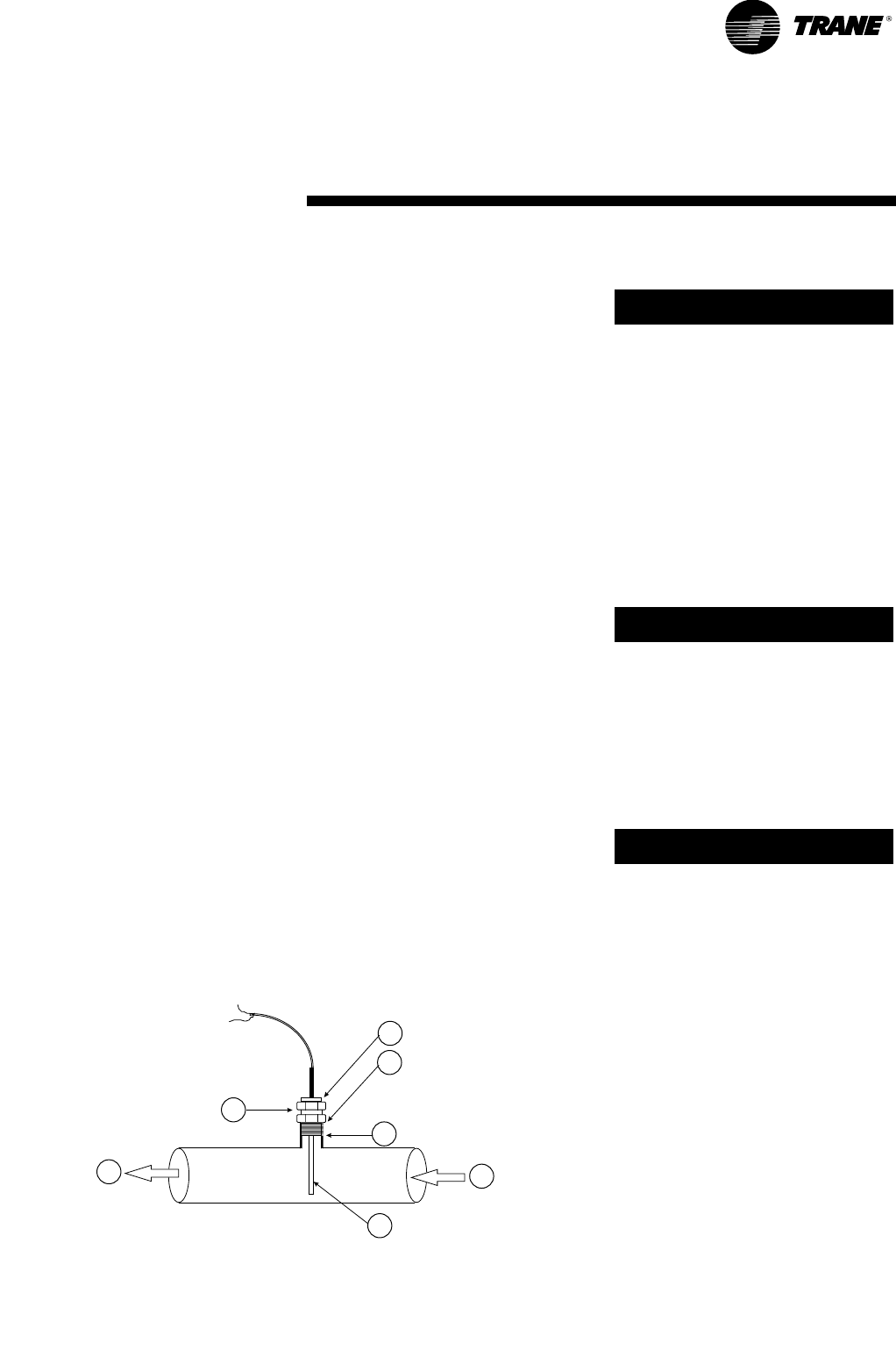

1

6

7

3

4

5

2

Figure 9: UCM water temperature sensor installation

1 In

2 Out

3 UCM sensor

4 ¼" NPT coupling (customer-supplied)

5 Compression fitting (Trane-supplied)

6 Fitting body

7 Clamping nut

RLC-SVX03A-E4