4 TRG-TRC004-EN

notes

period one

Compressor Types

gradually shrinking the volume of the refrigerant. Thus, they are called

positive-displacement compressors.

In contrast, centrifugal compressors use the principle of dynamic

compression, which involves converting energy from one form to another in

order to increase the pressure and temperature of the refrigerant. The

centrifugal compressor uses centrifugal force, generated by a rotating

impeller, to compress the refrigerant vapor.

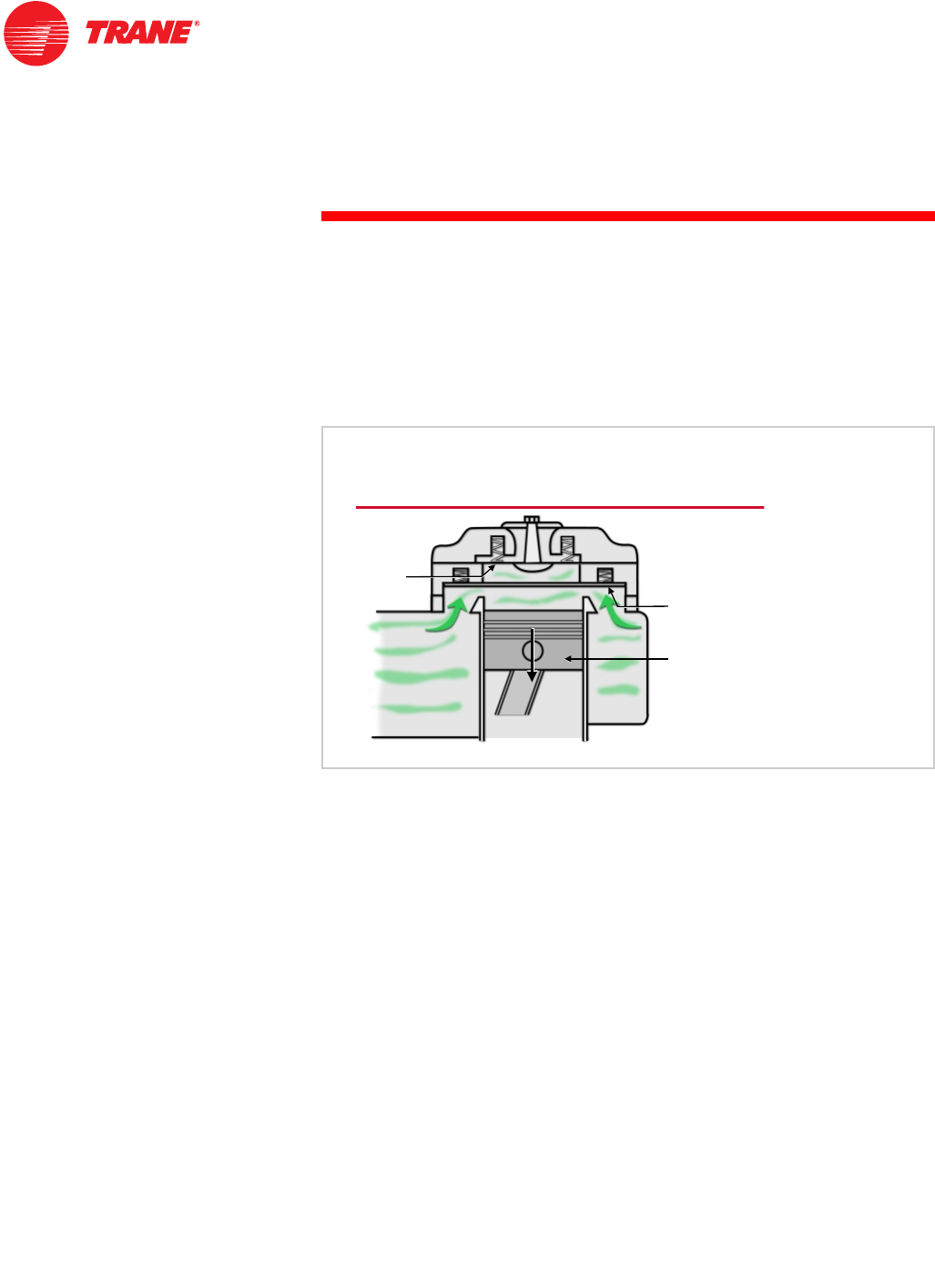

Reciprocating Compressor

The first type of compressor to be discussed is the reciprocating

compressor. The principles of operation for all reciprocating compressors are

fundamentally the same. The refrigerant vapor is compressed by a piston that

is located inside a cylinder, similar to the engine in an automobile. A fine layer

of oil prevents the refrigerant vapor from escaping through the mating

surfaces. The piston is connected to the crankshaft by a rod. As the crankshaft

rotates, it causes the piston to travel back and forth inside the cylinder. This

motion is used to draw refrigerant vapor into the cylinder, compress it, and

discharge it from the cylinder. A pair of valves, the suction valve and the

discharge valve, are used to trap the refrigerant vapor within the cylinder

during this process. In the example reciprocating compressor shown, the

spring-actuated valves are O-shaped, allowing them to cover the valve

openings around the outside of the cylinder while the piston travels through the

middle.

During the intake stroke of the compressor, the piston travels away from the

discharge valve and creates a vacuum effect, reducing the pressure within the

cylinder to below suction pressure. Since the pressure within the cylinder is

less than the pressure of the refrigerant at the suction side of the compressor,

the suction valve is forced open and the refrigerant vapor is drawn into the

cylinder.

5HFLSURFDWLQJ&RPSUHVVRU

SLVWRQ

SLVWRQ

UHIULJHUDQW

UHIULJHUDQW

YDSRU

YDSRU

F\OLQGHU

F\OLQGHU

GLVFKDUJH

GLVFKDUJH

YDOYH

YDOYH

URG

URG

VXFWLRQ

VXFWLRQ

YDOYH

YDOYH

LQWDNH

VWURNH

Figure 6