28 TRG-TRC004-EN

notes

period two

Compressor Capacity Control

methods of capacity control, many of them function in a manner similar to the

inlet vanes presented in this section of the clinic.

Inlet vanes “preswirl” the refrigerant before it enters the impeller. By

changing the refrigerant’s angle of entry, these vanes lessen the ability of the

impeller to take in the refrigerant. As a result, the compressor’s refrigerant-

pumping capacity decreases to balance with the evaporator load.

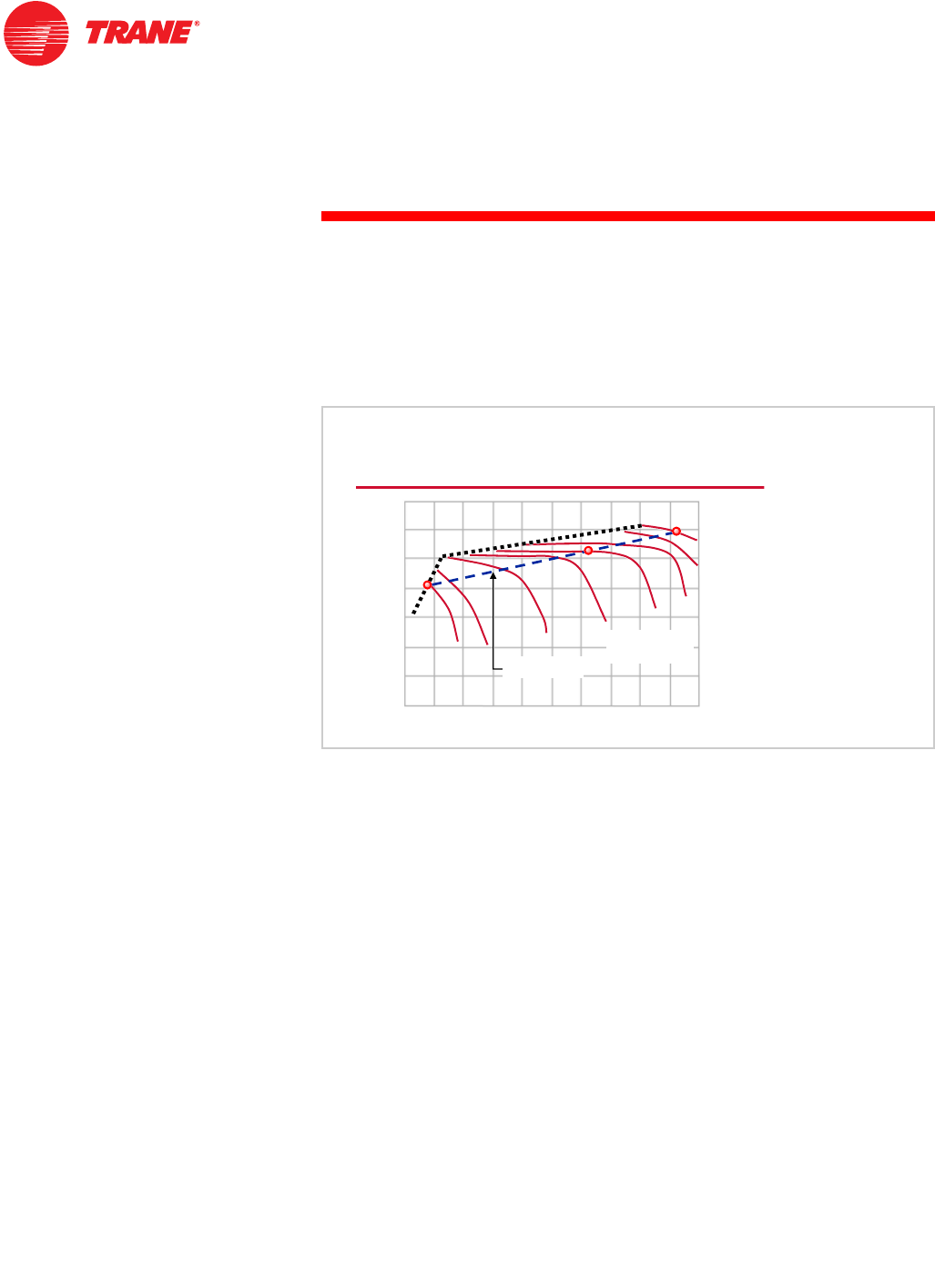

These curves represent the performance of a typical centrifugal compressor

over a range of inlet vane positions. The pressure difference between the

compressor inlet (evaporator) and outlet (condenser) is on the vertical axis and

compressor capacity is on the horizontal axis. The surge region represents the

conditions that cause unstable compressor operation.

As the load on the compressor decreases from the full-load operating point (A),

the inlet vanes partially close, reducing the flow rate of refrigerant vapor and

balancing the compressor capacity with the new load (B).

Less refrigerant, and therefore less heat, are transferred to the condenser. Since

the available heat rejection capacity of the condenser is now greater than

required, the refrigerant condenses at a lower temperature and pressure. This

reduces the pressure difference between the evaporator and the condenser.

Continuing along the unloading line, the compressor remains within its stable

operating range until it reaches C.

Inlet vanes on a centrifugal compressor allow it to unload over a broad capacity

range while preventing the compressor from operating in the surge region.

,QOHW9DQHV

SUHVVXUHGLIIHUHQFH

SUHVVXUHGLIIHUHQFH

FDSDFLW\

FDSDFLW\

V

X

U

J

H

V

X

U

J

H

$

XQORDGLQJOLQH

XQORDGLQJOLQH

YDQHSRVLWLRQ

YDQHSRVLWLRQ

GHJUHHV

GHJUHHV

&

%

Figure 40