34 TRG-TRC004-EN

notes

period three

The Compressor in a System

suction temperature for a specific application depends on the system operating

conditions and the evaporator design.)

Evaporator freeze protection in a chilled-water application is accomplished by

sensing the temperature of the water in the evaporator. If the water approaches

32°F [0°C], the compressor is shut off to protect the evaporator from freezing.

Most chilled water-equipment includes this protection as part of the controls for

the equipment.

In a direct-expansion (DX) application, where the refrigerant in the evaporator is

cooling air, frost protection can be accomplished in a number of ways. As

mentioned, if the surface temperature of the coil gets too cold, the moisture

that condenses out of the air can form frost on the surface of the coil. This “coil

frosting” is detrimental to system performance and compressor reliability.

Historically, in DX air-conditioning applications, hot gas bypass, coil pressure

regulators, and defrost cycles initiated by a timer, pressure sensor, or

temperature sensor are a few of the methods that have been used to prevent

evaporator frosting. This clinic will focus on two of these—a defrost cycle

initiated by a temperature sensor and hot gas bypass.

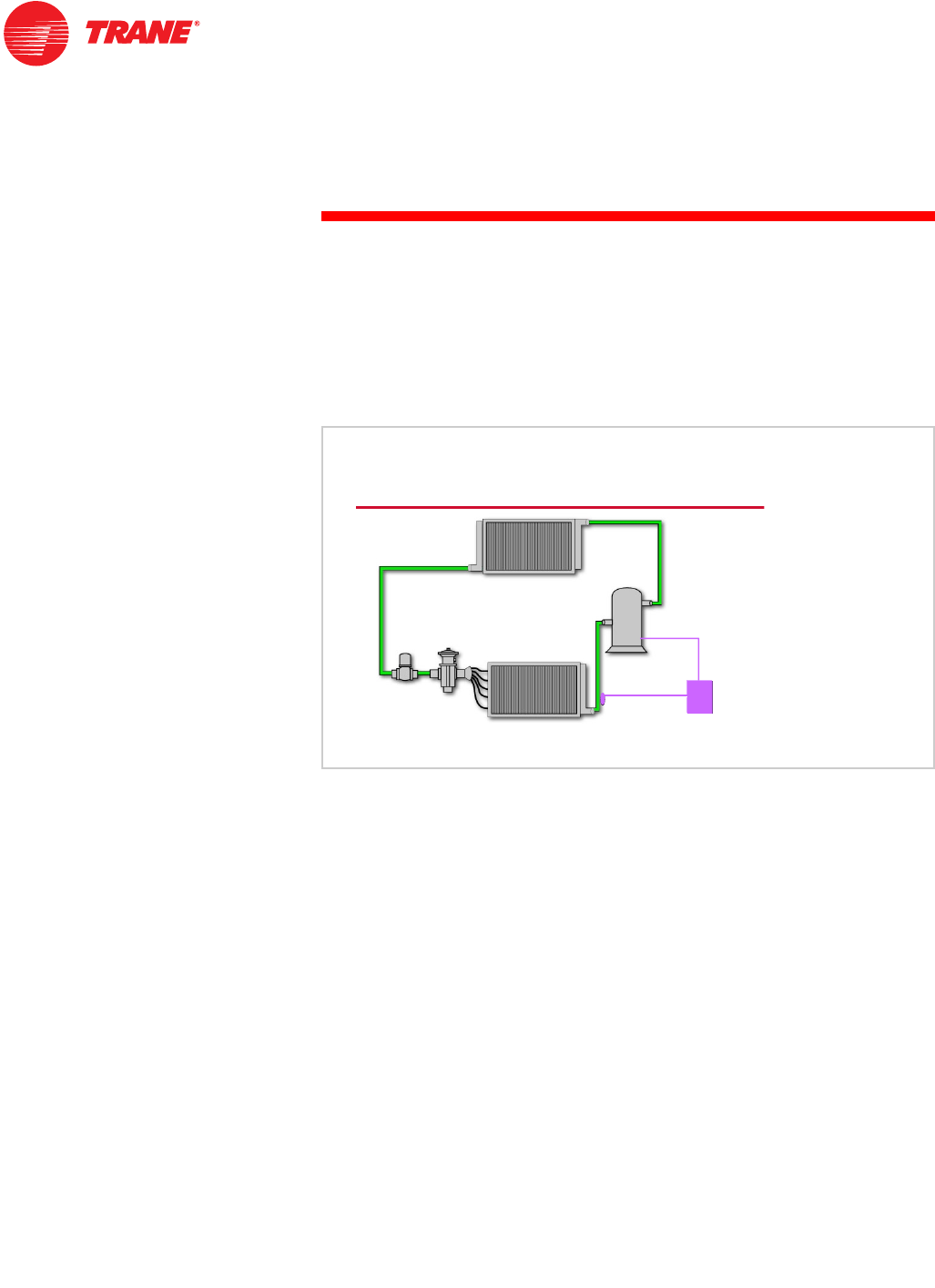

A temperature sensor on the suction line leaving the evaporator is used to

determine if the coil reaches a frosting condition. Compressors are turned off

and the supply fan continues to run to de-ice the coil. Timers prevent the

compressors from rapid cycling.

This control scheme (referred to by Trane as FROSTAT™) is especially well

suited for equipment using scroll compressors, which are designed to start and

stop much more often than large reciprocating compressors.

6HQVLQJ6XFWLRQ7HPSHUDWXUH

H[SDQVLRQ

H[SDQVLRQ

YDOYH

YDOYH

HYDSRUDWRU

HYDSRUDWRU

FRQGHQVHU

FRQGHQVHU

FRPSUHVVRU

FRPSUHVVRU

VXFWLRQ

VXFWLRQ

OLQH

OLQH

VHQVRU

VHQVRU

Figure 48