TRG-TRC004-EN 35

period three

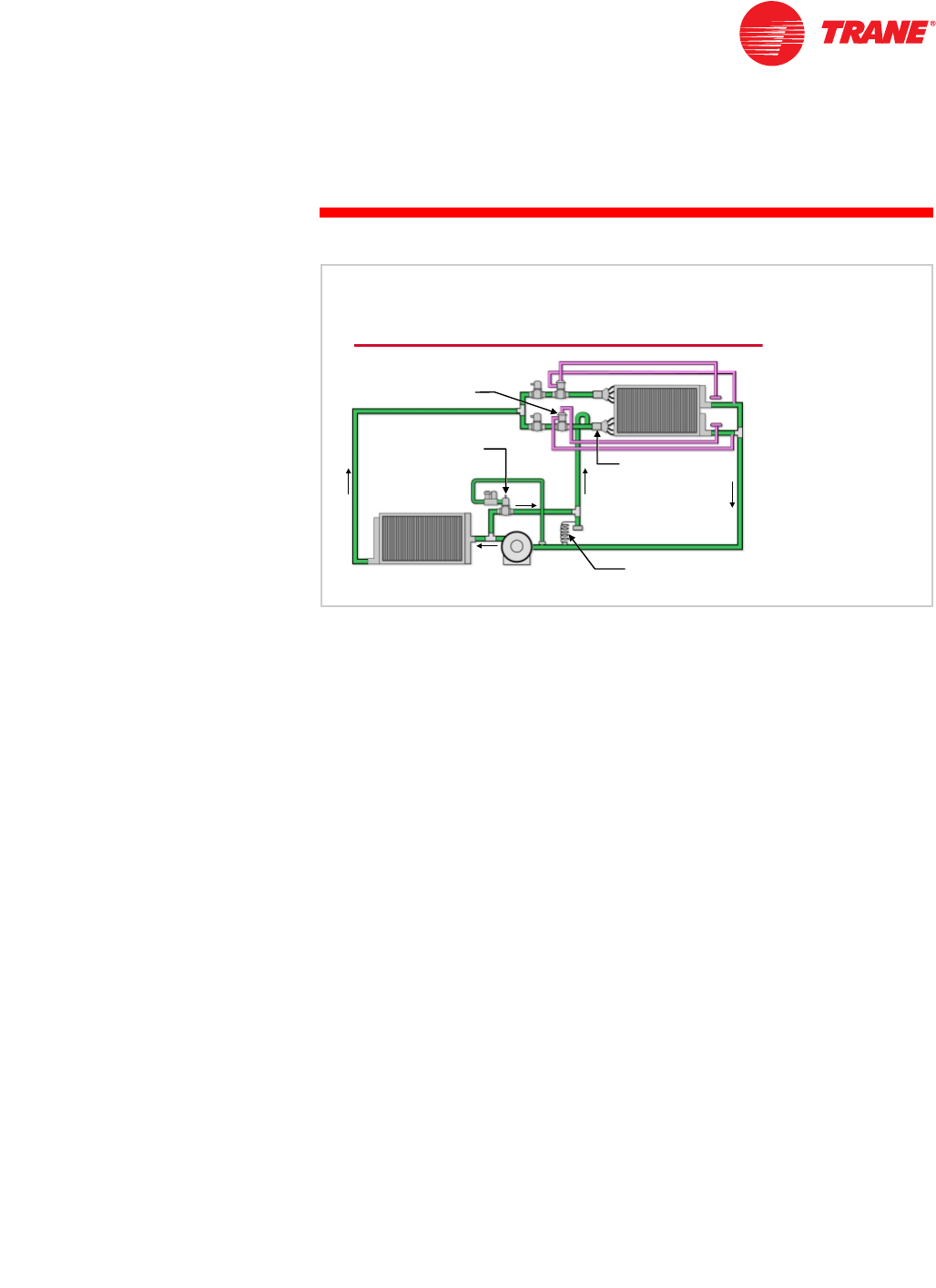

The Compressor in a System

notes

Hot gas bypass may be another solution for preventing evaporator frosting in

DX applications. Hot gas bypass diverts hot, high-pressure refrigerant vapor

from the discharge line to the low-pressure side of the refrigeration system.

This added “false load” helps to maintain an acceptable suction pressure and

temperature. Hot gas bypass, however, fails to reduce energy consumption

because it does not allow the compressor to shut off at these low load

conditions.

In a DX application, there are two bypass methods used. The first method

bypasses refrigerant vapor from the compressor discharge line to the inlet of

the evaporator coil. Sensing a decrease in suction pressure, a pressure-

actuated valve opens to bypass hot refrigerant vapor from the compressor

discharge line to the inlet of the evaporator coil, between the expansion valve

and the liquid distributor. This increases the rate at which liquid refrigerant is

boiled off within the evaporator coil and causes the temperature of the

refrigerant leaving the coil to rise. Sensing this increased temperature, the

expansion valve feeds additional refrigerant to the coil, increasing the suction

pressure and temperature.

The principal advantage of hot gas bypass to the evaporator inlet is that the

refrigerant velocity in the evaporator and suction line is higher at low loads.

This promotes a uniform movement of oil through the evaporator coil and

suction piping. When the evaporator is located above the compressor, as

shown, the holdup of oil within the vertical hot-gas-bypass riser must be

considered. Since the flow rate within the hot-gas-bypass line modulates over a

wide range, no size of pipe can ensure adequate velocity to carry oil up the

riser. Oil will collect at the base of the vertical riser when the bypass valve

throttles to lower flow rates. This problem is commonly addressed by adding a

small oil return line between the base of the riser and the suction line.

+RW*DV%\SDVVWR(YDSRUDWRU,QOHW

HYDSRUDWRU

HYDSRUDWRU

FRQGHQVHU

FRQGHQVHU

FRPSUHVVRU

FRPSUHVVRU

KRWJDV

KRWJDV

E\SDVVYDOYH

E\SDVVYDOYH

H[SDQVLRQYDOYH

H[SDQVLRQYDOYH

GLVWULEXWRU

GLVWULEXWRU

VXFWLRQOLQH

VXFWLRQOLQH

OLTXLGOLQH

OLTXLGOLQH

RLOUHWXUQOLQH

RLOUHWXUQOLQH

Figure 49