2 TRG-TRC004-EN

notes

Introduction

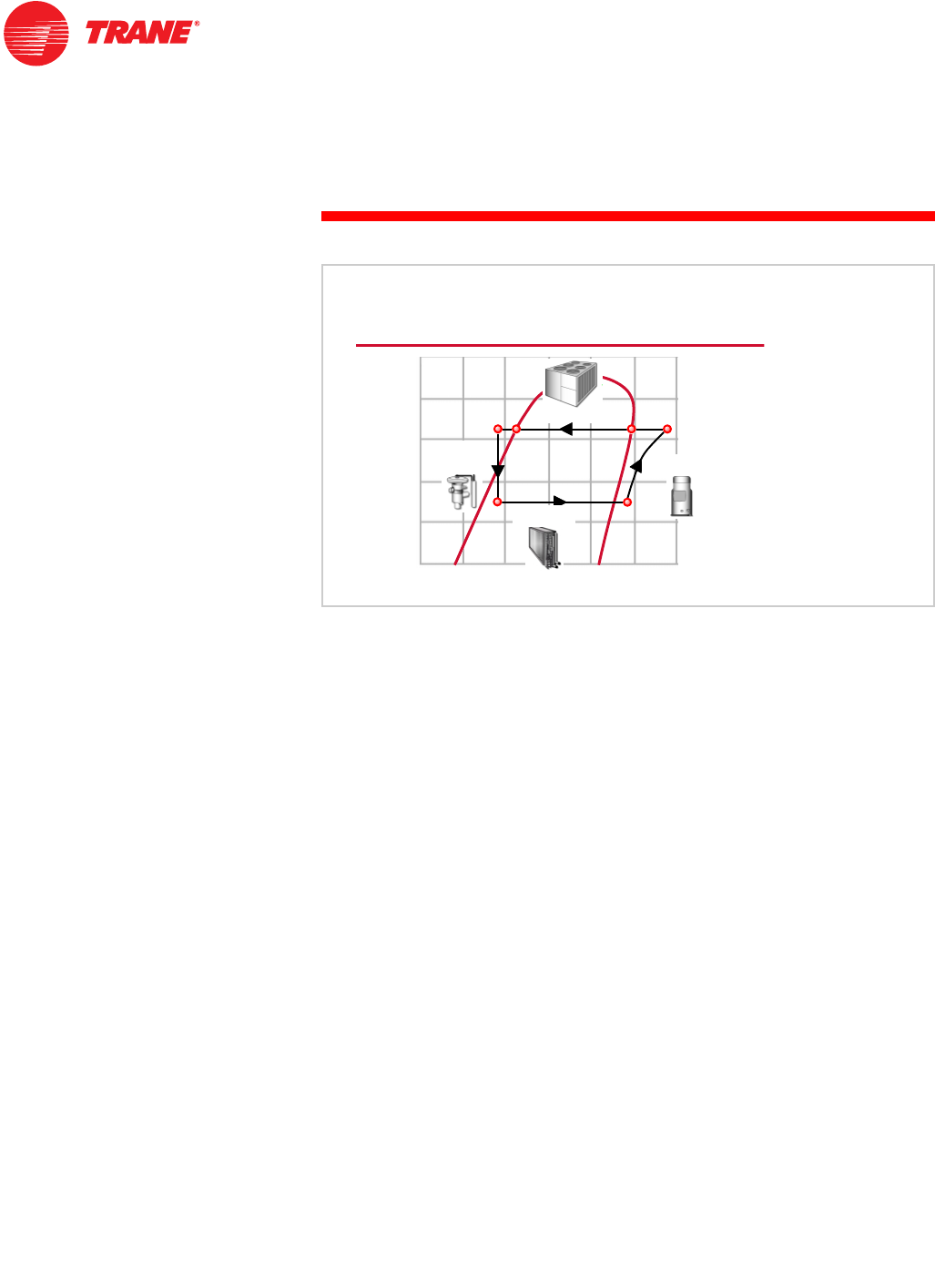

The pressure–enthalpy (P–h) chart plots the properties of a refrigerant:

refrigerant pressure (vertical axis) versus enthalpy, or heat content (horizontal

axis). A diagram of the basic vapor-compression refrigeration cycle can be

superimposed on a pressure–enthalpy chart to demonstrate the function of

each component in the system.

Refrigerant enters the evaporator in the form of a cool, low-pressure mixture of

liquid and vapor (A). Heat is transferred from the relatively warm air or water to

be cooled to the refrigerant, causing the liquid refrigerant to boil and in some

cases superheat (B). The resulting vapor (B) is then pumped from the

evaporator by the compressor, which increases the pressure and temperature

of the refrigerant vapor. Notice that during the compression process (B to C),

the heat content (enthalpy) of the vapor is increased. The mechanical energy

used by the compressor to increase the pressure of the refrigerant vapor is

converted to heat energy, called the heat of compression. This causes the

temperature of the refrigerant to also rise as the pressure is increased.

The resulting hot, high-pressure refrigerant vapor (C) enters the condenser

where heat is transferred to ambient air or water at a lower temperature. Inside

the condenser, the refrigerant desuperheats (C to D), condenses into a liquid (D

to E), and, in some cases, subcools (E to F). The refrigerant pressure inside the

condenser is determined by the temperature of the air or water that is available

as the condensing media.

This liquid refrigerant (F) then flows from the condenser to the expansion

device. The expansion device creates a pressure drop that reduces the pressure

of the refrigerant to that of the evaporator. At this low pressure, a small portion

of the refrigerant boils (or flashes), cooling the remaining liquid refrigerant to

the desired evaporator temperature (A). The cool mixture of liquid and vapor

refrigerant travels to the evaporator to repeat the cycle.

H[SDQVLRQ

H[SDQVLRQ

GHYLFH

GHYLFH

$

)

FRQGHQVHU

FRQGHQVHU

SUHVVXUH

SUHVVXUH

HQWKDOS\

HQWKDOS\

5HIULJHUDWLRQ&\FOH

%

&

('

HYDSRUDWRU

HYDSRUDWRU

FRPSUHVVRU

FRPSUHVVRU

Figure 3