GB

14

TexPerfect Flexio 525

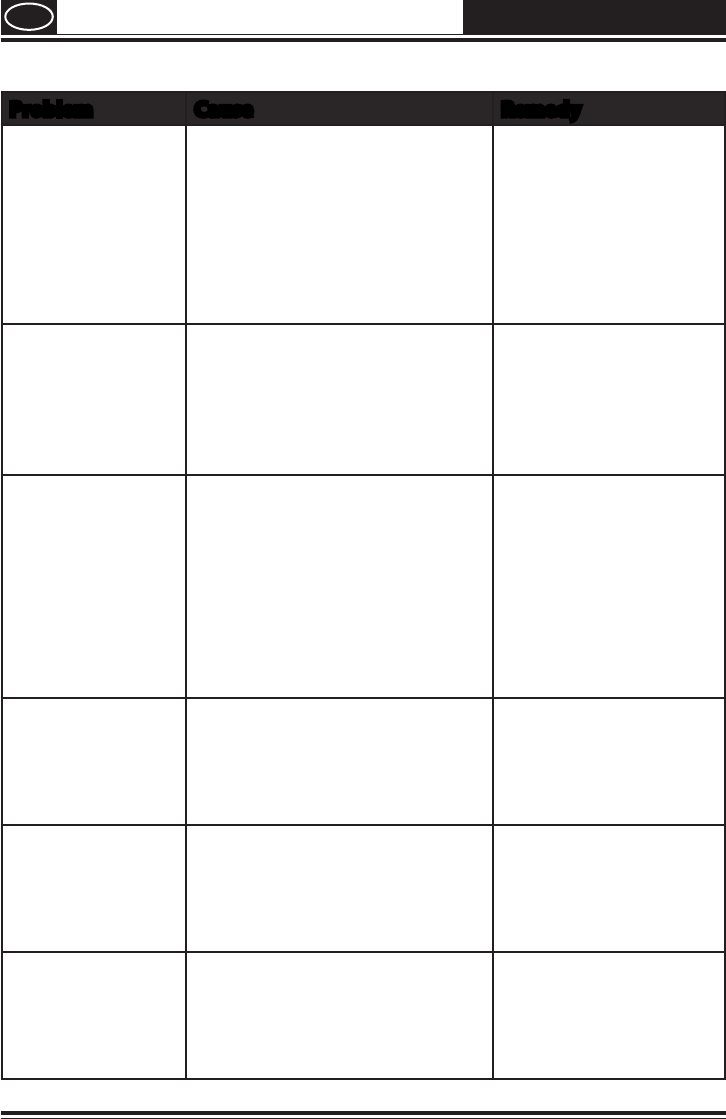

21. Correction of Malfunctions

Problem Cause Remedy

No coating material

emerges from the

nozzle

•

Nozzle clogged

•

Feed tube clogged

•

Material volume setting turned

too far to the left (-)

•

Feed tube loose

•

No pressure build-up in container

•

Ventilating bore (Fig. 10,1)

clogged

➞ Clean

➞ Clean

➞ Turn to the right (+)

➞ Insert

➞ Tighten container

➞ Clean

Coating material

drips from the

nozzle

•

Nozzle loose

•

Nozzle worn

•

Nozzle seal is missing or worn

•

Coating material assembly at air

cap, nozzle or needle

➞ Tighten

➞ Change

➞ Insert an intact nozzle

seal

➞ Clean

Atomisation too

coarse

•

Coating material too thick

•

Material volume too large

Material volume adjusting screw

turned too far to the right (+)

•

Nozzle contaminated

•

Air lter heavily soiled

•

Too little pressure build-up in

container

•

Amount of air too low

➞ Dilute

➞ Turn material volume

adjusting screw to the

left (-)

➞ Clean

➞ Change

➞ Tighten container

➞ Increase air quantity

Spray jet pulsates

•

Coating material in container

running out

•

Air lter heavily soiled

•

Nozzle seal is missing or worn

➞ Rell

➞ Change

➞ Insert an intact nozzle

seal

Coating material

causes "paint tears"

•

Too much coating material

applied.

➞ Turn material volume

adjusting screw to the

left (-)

➞ Leave it to dry and

then sand down

Too much fog of

coating material

(Overspray)

•

Distance to the object too large

•

Too much coating material

applied

•

Amount of air too high

➞ Reduce distance

➞ Turn material volume

adjusting screw to the

left (-)

➞ Decrease air quantity