ProSpray 3.39 15

GB

Remedy in case of faults

Digital Electronic Spray Control (DESC) Error Messages

The following error message screens appear whenever the Digital Electronic

Spray Control (DESC) detects a problem with the sprayer. Once a problem

occurs and the error message appears, the sprayer will shut down.

Before proceeding, relieve any pressure remaining in the

system (valve position PRIME k). Additionally, follow all

other warnings to reduce the risk of an injection injury,

injury from moving parts or electric shock. Always unplug

the sprayer before servicing!

Check Transducer Screen

CHECK

TRANSDUCER

The Check Transducer screen appears when

the transducer has become disconnected or

is defective. Take the sprayer to a Wagner

authorizedservicecenterforrepair.

Check Motor Screen

CHECK

MOTOR

The Check Motor screen appears when the

motor or motor sensor is defective. Take the

sprayertoaWagnerauthorizedservicecenter

for repair.

Low Voltage Screen

LOW

VOLTAGE

TheLowVoltagescreenappearswhenthe

sprayer shuts down because of low input

voltage. Check the power supply and correct

the problem. Restart the sprayer.

High Motor Temperature Screen

HIGH MOTOR

TEMPERATURE

The High Motor Temperature screen appears

when the temperature of the motor has risen too

high.TakethesprayertoaWagnerauthorized

service center for repair.

High Control Temperature Screen

HIGH CONTROL

TEMPERATURE

The High Control Temperature screen appears

when the temperature of the Digital Electronic

Spray Control (DESC) has risen too high. Take

thesprayertoaWagnerauthorizedservicecenterforrepair.

High Mechanical Load

HIGH MECHANICAL

LOAD

The High Mechanical Load screen appears when

the sprayer shuts down because of high current

or when the sprayer goes into current fold back

mode.TakethesprayertoaWagnerauthorizedservicecenterforrepair.

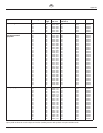

Type of malfunction

A. Unitdoesnotstart

B. Unitdoesnotdrawinmaterial

C. Unitdrawsinmaterial,butthe

pressure does not build up

D. Coating material exits at the top of

the uid section

E. Increased pulsation at the spray

gun

F. Poor spray pattern

G. Unitlosespower

Possible cause

1. No voltage applied.

2. Pressure setting too low.

3. ON/OFF switch defective.

1. ReliefvalveissettoSPRAY(p spray).

2. Filter projects over the uid level and

sucks air.

3. Filter clogged.

4. Suction hose/suction tube is loose, i.e.

the unit is sucking in outside air.

1. Tip heavily worn.

2. Tip too large.

3. Pressure setting too low.

4. Filter clogged.

5. Coating material ows through the

return hose when the relief valve is in

theSPRAY(p spray) position.

6. Packings sticky or worn.

7. Valveballsworn.

8. Valveseatsworn.

1. Upperpackingisworn.

2. Piston is worn.

1. Incorrect high-pressure hose type.

2. Tip worn or too large.

3. Pressure too high.

1. Tip is too large for the coating

material which is to be sprayed.

2. Pressure setting incorrect.

3. Volumetoolow.

4. Coating material viscosity too high.

1. Pressure setting too low.

Measures for eliminating the malfunction

1. Check voltage supply.

2. Turn up pressure control knob.

3. Replace.

1. Set relief valve to PRIME (k circulation).

2. Rell the coating material.

3. Clean or replace the lter.

4. Clean connecting points. Tighten suction tube.

1. Replace

2. For selection of a smaller tip, see Tip table on Page 20.

3. Turn pressure control knob clockwise to increase.

4. Clean or replace the lter.

5. Remove and clean or replace relief valve.

6. Remove and clean or replace packings.

7. Remove and replace valve balls.

8. Remove and replace valve seats.

1. Remove and replace packing.

2. Remove and replace piston.

1. Only use WAGNER original-high-pressure hoses in order

to ensure functionality, safety and durability.

2. Replace tip.

3. Turn pressure control knob to a lower number.

1. Replace tip, see Tip table on Page 20.

2. Turn pressure control knob until a satisfactory spraying

pattern is achieved.

3. Clean or replace all lters.

4. Thinoutaccordingtothemanufacturer’sinstructions.

1. Turn pressure control knob clockwise to increase.

9. Remedy in case of faults