8 ProSpray 3.39

GB

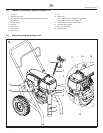

Description of unit

3.5 Technical data

Voltage: 100-110VoltAC,50Hz

Max. current consumption: 15 A / 20 A

Power cord: 3 x 1.5 mm

2

– 6 m or 4.6 m

Acceptance capacity: 2000 Watt

Max. operating pressure: 221 bar (22,1 MPa)

Volume ow at 12 MPa

(120 bar) with water: 5.0 l/min

Max tip size: 0.039 inch – 0.99 mm

Max. temperature of the

coating material: 43°C

Max viscosity: 30.000 MPa·s

Weight: 50 kg

Special high-pressure hose: DN 6 mm, 15 m, connection

thread M 16 x 1.5

Dimensions (L X W X H): 632 x 568 x 743 mm

Max sound pressure level: 80 dB (A) *

* Placeofmeasuring:1mindistancefromtheunitand1.6

m above the oor, 12 MPa (120 bar) operating pressure,

reverberant oor.

3.6 Transportation

Pushing or pulling the unit

Pull out the handle (Fig. 2, Item 1) until it will come no further. Insert

the handle – push the buttons (2) on the spars, and then push in the

handle.

2

1

2

3.7 Transportation in vehicle

Secure the unit with a suitable fastening.

3.8 Paint material setup

i

This sprayer comes with a lter assembly installed.

If you plan to spray with untextured painting

materials, leave the lter installed.

3.9 Textured material setup

i

This sprayer comes with a lter plug that should be

put in place of the lter whenever spraying textured

materials. Follow these steps to remove the lter

and install the plug.

1. Loosen and remove the lter housing (1) by hand.

2. Remove the adapter spring (2), lter (3), bearing ring (4) and

spring (5) from the housing (7).

3. Make sure the O-ring (6) is still in place. Thread the lter plug

(8) into the housing until secure.

i

The lter plug should be hand-tightened, but make

sure it is seated fully into the lter housing.

1

2

4

5

3

6

8

7

i

If using this sprayer with textured materials, it is

important that the lter inside of the spray gun be

removed. See section 8.3.

i

If the sprayer will be used for spraying textured

products, removal of the inlet screen in the foot

valve may be necessary. This will allow proper

priming and ow of the textured product. See

section 8.4.