6 720 608 263

Installation instructions

13

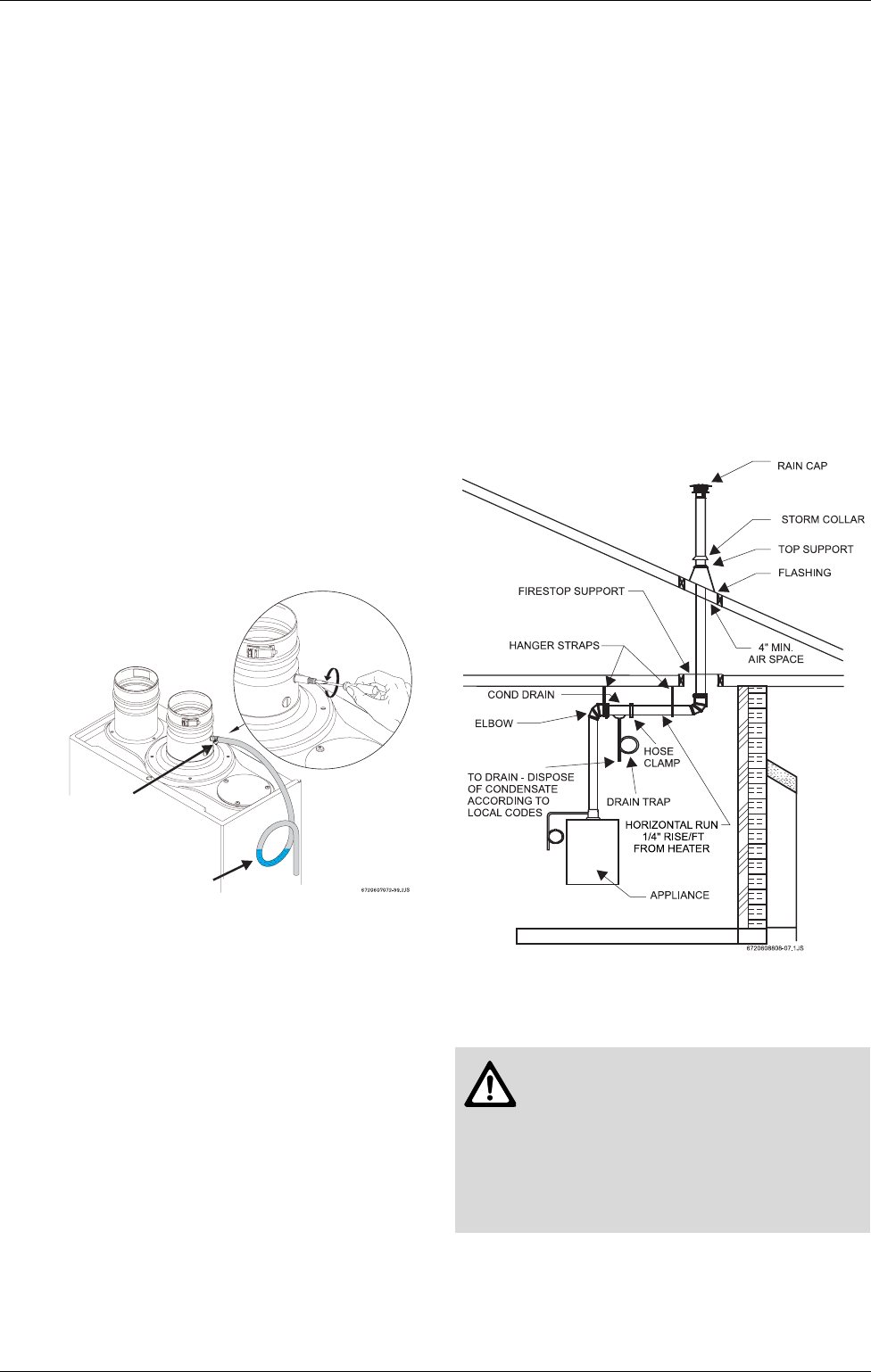

3.6.3 Condensate drain tube requirements

Exhaust collar condensate drain installation

(supplied with heater)

B The condensate drain tube kit must be used for all

installation types. Failure to properly install

condensate drain will void the warranty.

B When installing the condensate drain tube kit on the

exhaust collar (see diagram below), be sure to form a

trap by means of a 3" (76.2 mm) loop partially filled

with water. This loop must be as low as possible to

allow proper drainage of condensate. The supplied

tube is 3/8" ID high temperature silicone and must be

attached to the condensate port on the exhaust collar

with its supplied gear clamp (first remove brass

screw from port).

B To increase tube length, connect vinyl tubing (not

supplied with heater) to the supplied tube. Do not

reduce tubing diameter when using connector or

additional tubing.

B The condensate must be disposed of according to

local regulations.

Fig. 12 Exhaust collar condensate drain installation

Note: No part of supplied silicone tube should be

installed above condensate tapping or improper drain-

age may occur. (see Fig. 12).

External condensate drain installation (not

supplied)

An additional external condensate drain must be

installed under the following conditions:

• Vertical terminating vent installations

• Horizontal terminating vent installations where the

total vent length is greater than 5 feet

• Vent installation where any section of the exhaust

vent pipe passes through an unconditioned space.

Note: Condensate must be disposed of according to

local codes.

Note: Do not install condensate drain in areas where it

may freeze.

1. Install condensate drain as close to heater as

possible.

2. Use 3/8" ID high temperature silicone tubing to

connect to condensate drain port. Do not use copper

piping for any portion of the condensate drain.

3. Form a condensate trap by means of a 3" loop and

fill bottom of loop with water.

4. To increase the tube length, connect to end of the

high temperature silicone tubing with vinyl tubing,

PVC or CPVC pipe. Do not reduce the internal

diameter at any point.

5. Dispose of condensate according to local codes.

Fig. 13 Required condensate drain installation

(Combustion air piping not shown)

3.6.4 Room sealed installation (Twin pipe)

B Although it is permitted to draw combustion air from

inside the structure in warm climates, the recom-

mended method is to provide combustion air through

Condensate port on exhaust collar

2. Fit tube with

gear clamp

3. Loop size and location. Coil tube into 3” loop

with nylon tie (don't crimp tubing) and fill bottom

of loop with water

1. Remove brass hex head

screw

Warning: In areas where outdoor

temperatures commonly fall below

36°F, a twin pipe venting system is

required. Failure to do so may result in

cold outside air being drawn across the

heat exchanger causing it to freeze and

burst. This failure is not covered under

the manufacturer's warranty.