6 720 608 263

30

Maintenance and service

pipe (approx 1.5" inserted). Avoid air gaps between

probe and measuring port as it can alter readings.

Fig. 40 Measuring port

B While holding the Program (P) button, turn the ON/

OFF switch to ON (I) position (see Fig. 41). As soon

as ‘188’ flashes on the display, release the Program

button. The display should now read P2. Press

button until “P1” appears on display.

Fig. 41

B. Measuring CO

2

(Cover Installed):

B Open all hot water taps to achieve a flow rate of at

least 4 gallons per minute. (1 tub and 2 sinks should

be sufficient).

B Record the CO

2

reading in P1 below. (Analyzer

reading may take several minutes to stabilize).

B Press the ‘ ’ button until P2 appears. Unit will

ramp down to low fire and the water flow should

decrease.

B Record the CO

2

reading in P2 below.

P1 CO

2

Reading: % CO

2

P2 CO

2

Reading: % CO

2

C. Adjusting CO2 (cover removed):

Note: when making adjustments with the front cover off,

CO

2

values will be 0.3 - 0.5% lower than with the front

cover on. Adjust values accordingly to make target num-

bers in Table 10 when cover is secured.

Compare your readings to those found in Table 10. If

CO

2

readings are off, make adjustments as outlined

below.

Note: P1 adjustment will change the P2 reading. Con-

firm the P1 value BEFORE adjusting the P2 level.

1. If P1 CO

2

level is off:

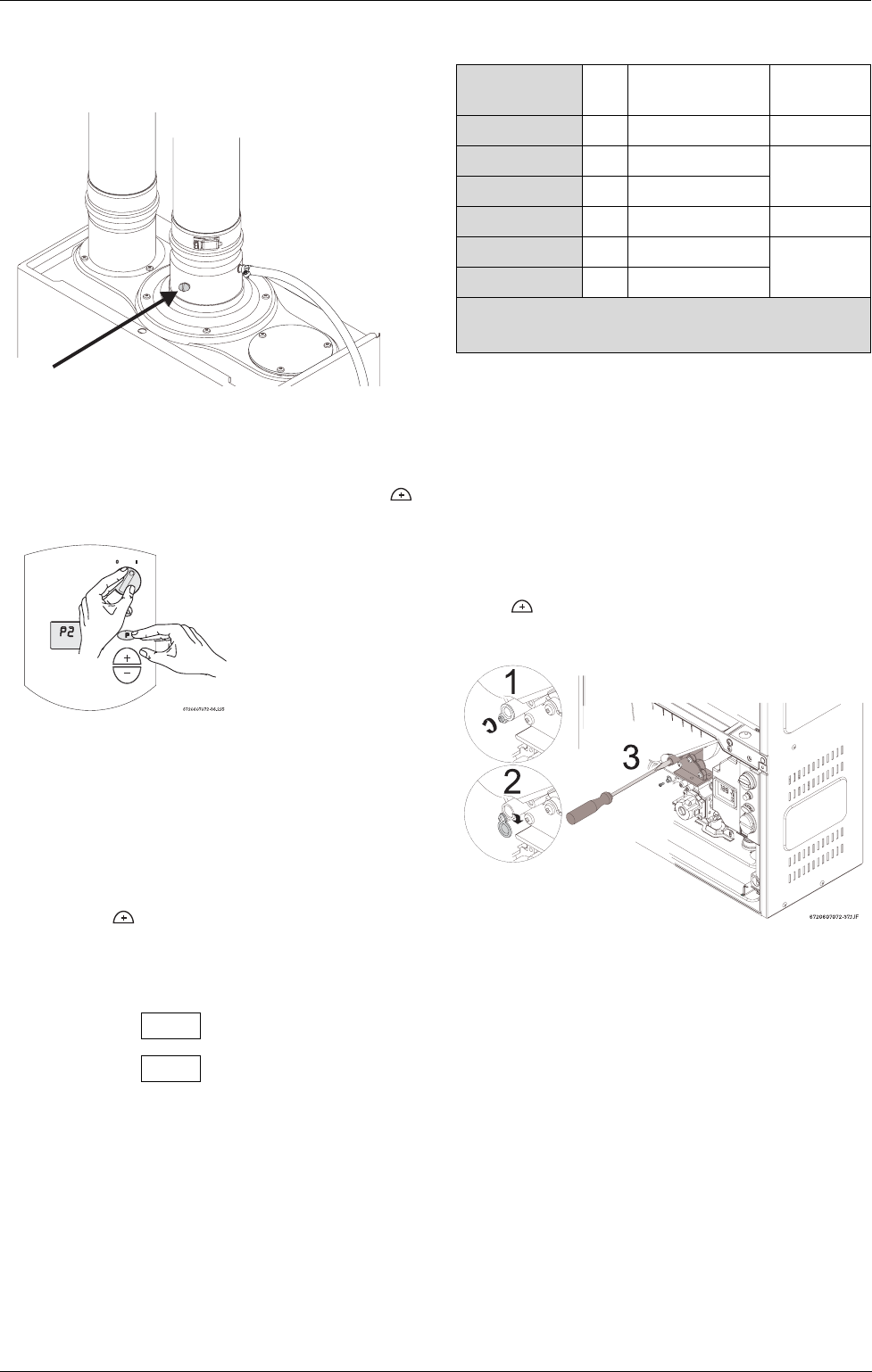

B Loosen yellow painted philips screw (1) and cover

should rotate down (2) revealing a recessed brass

slotted screw. Fig. 42.

B Turning the slotted screw counter clockwise will

raise P1 CO

2

levels and clockwise will lower P1

CO

2

levels. Adjustments to the slotted screw will

also change P2 CO

2

levels.

B After bringing the P1 CO

2

readings in range, press

the button to enter the P2 mode. Verify CO

2

readings in P2 mode.

Fig. 42 Adjusting P1 CO

2

level

2. If P2 CO

2

level is off:

B Remove yellow painted #40 Torx cover from the front

of the gas valve. (Fig. 43) A plastic #40 Torx screw

will be revealed.

B Turning the plastic #40 Torx screw counter

clockwise will lower P2 CO

2

levels and clockwise

will raise P2 CO

2

levels.

Note: These screw adjustment are very sensitive and

may take several minutes to stabilize.

CO

2

level

Max CO

level

Nat. Gas

max. input P1 9.7 ± 0.3 %

300 ppm

min. input P2 9.5 ± 0.5 %

LP Gas

max. input P1 10.7 ± 0.3 %

300 ppm

min. input P2 10.5 ± 0.5 %

* Final reading must be confirmed with the front cover on,

CO

2

levels increase when the cover is installed.

Table 9