Chicago Pneumatic Compressors

62 305 258 65

01/2008

Page 18

• Pressure regulation for low rates of flow

For an air consumption rate lower than the minimum rate of flow

for the machine, the pressure is adjusted by the machine's time-

delayed START/STOP controls.

Since the operation element cannot function below a certain speed

(corresponding to the minimum output), the compressor conti-

nues to run and compress at the minimum speed until the pres-

sure reaches the limit called "Indirect shutdown ".

Once this threshold has been reached, the motor will stop, the

machine will go into stand-by mode after a certain period of

inactivity and the full drainage process will be carried out.The

pressure then drops towards the indicated pressure and, at the

end of the minimum time delay (since reaching the no-load pres-

sure), the drive allows the motor to restart. The pressure then

rises again and the cycle starts over (fig. 14 d).

To avoid pumping the system - frequent stop / start - drainage

time may be increased

(cf. notice AIRLOGIC).

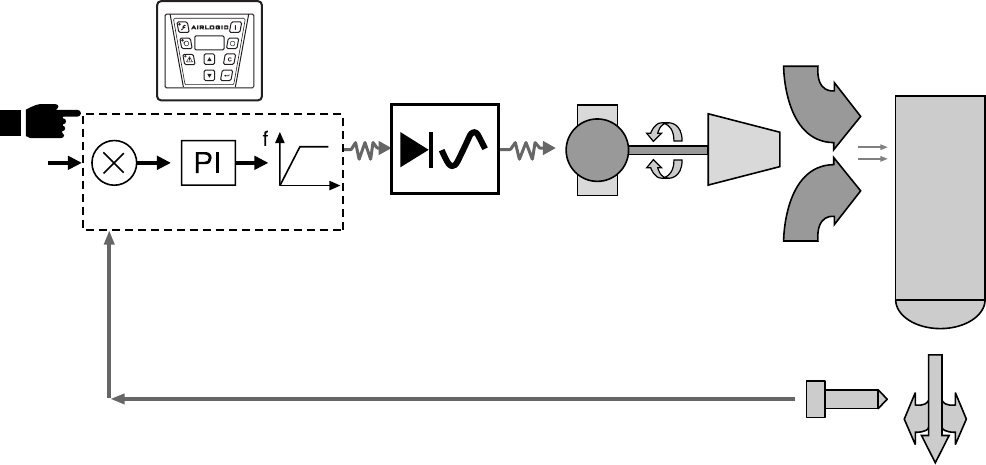

Fig. 14a

The principle of the pressure regulation by variable speed

• Energy saving

For demand of compressed air within the machine's flow range -

min flow to max flow, the frequency converter or the variable

speed drive feed the motor in order to ensure that it turns at the

speed required to supply air demand both for pressure and flow.

It is used to adjust the power supply to the motor (and thus the

machine) to the exact power requirement for the compression of

the air, without a drainage stage being necessary.

COMMENT :

Energy savings are increased if machine maintenance is carried out

in accordance with the maintenance instructions and frequency.

Controller

Pressure

required

Drive

Motor Compressor

unit

Tank

System

Pressure sensor

Frequency speed