maintenance

WARNING: FOR YOUR OWN SAFETY, TURN

SWITCH "OFF" AND REMOVE PLUG FROM POWER

SOURCE OUTLET BEFORE MAINTAINING OR

LUBRICATING YOUR BAND SAW.

Tires

Pitch and sawdust that build up on the tires should

be removed with a stiff brush or scraped off with a

piece of wood.

CAUTION: To avoid damaging the tires do not use a

sharp knife or any kind of solvent.

When the tires become worn they should be replaced.

When replacing the tires, stretch them around the

wheels but do not glue them on.

ADJUSTING BAND SAW BEVEL TRAVEL

If the band saw will not hold its position when at a

bevel angle, and before the bevel lock is locked, or if

it is difficult to change the bevel angle, an adjustment

is necessary to correct the force required to bevel

the band saw.

To adjust the force required to bevel the band saw,

locate the three (3) capscrews holding the frame to

the motor mount. The capscrews are located in the

recessed area behind the hub of the lower wheel at

the 2 o'clock, 6 o'clock, and 10 o'clock positions. Use

a 3!16-inch hexagonal "L" wrench that has a 4-inch

leg, reach between the spokes of the lower wheel to

the capscrews. Adjust the capscrews equally until

the bevel action is smooth and the saw will hold its

position before the bevel lock is locked.

General Maintenance

Keep your band saw clean. Remove the sawdust

from the inside. Vacuum or blow out frequently,

Do not allow filth to build up on the table, the guides

orthe back-up bearings. Clean them with Craftsman

Gum and Pitch Remover.

CAUTION: Do not immerse the backup bearings in

the gum and pitch remover.

Put a thin coat of paste wax on the table so that the

wood slides easily while cutting.

Light Bulb

To replace the light bulb remove the front cover, Use

a phillips screwdriver to remove the lens and replace

the bulb. The light bulb is a 25 watt bayonet mount

bulb.

Motor

Frequently blow or vacuum out any sawdust from

the motor. Follow lubrication instruction on the

motor label.

WARNING: TO AVOID EYE INJURY FROM BLOW-

ING DEBRIS, WEAR SAFETY GOGGLES WHEN

BLOWING OUT SAWDUST.

WARNING: TO AVOID ELECTROCUTION OR FIRE,

IMMEDIATELY REPLACE A WORN, CUT, OR

DAMAGED POWER CORD.

Lubrication

All of the ball bearings are packed with grease at the

factory. They require no further lubrication.

ADJUSTING THE UPPER BLADE GUIDE

TRAVEL

If the upper guide bar will not move up and down

easily or falls when the lock knob is loosened, the

following adjustment should be performed.

1. Remove the Guide Bar Lock Knob and the

washer which is under it.

2. Using a 7/16" socket or wrench, tighten the nut

which is under the washer to just tight.

3. Then loosen the same nut 1 turn.

4. Move the guide bar up and down to check for

smooth movement while still holding its position

when released.

5. Make further adjustments to the nut as required

to get the guide bar to move smoothly and hold

its position when released.

6. Reinstall the washer and Guide Bar Lock Knob.

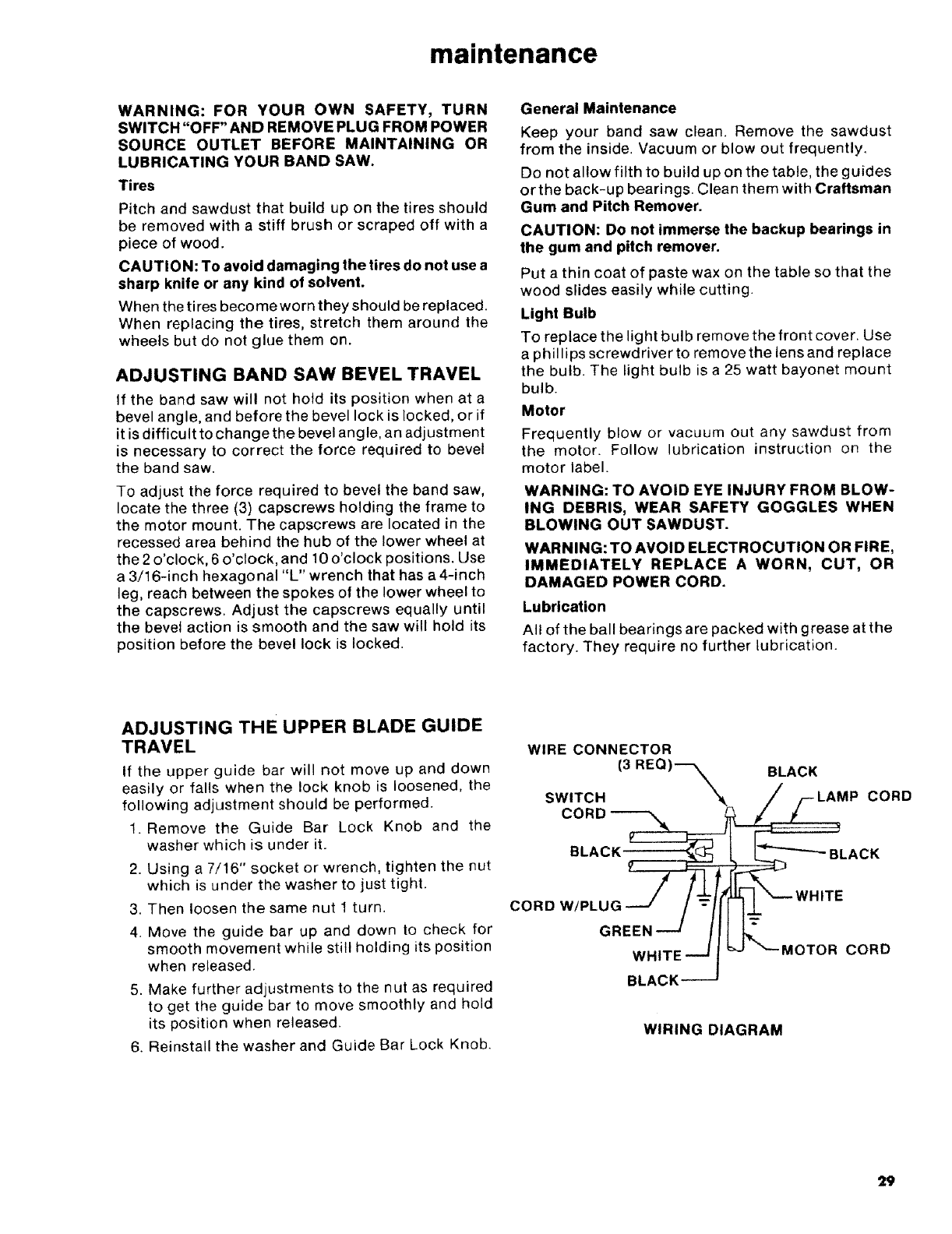

WIRE CONNECTOR

SWITCH (3 REQ)---_

BLACK

CORD W/PLUG

GRE

BLACK

WIRING DIAGRAM

BLACK

CORD

BLACK

CORD

29