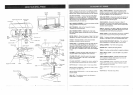

REMOVINGCHUCK(FIG.Z)

1. Withtheswitch"OFF",openthejawsofthechuckas

wideaspossiblebyturningthechuckcounterclockwise.

2. Tapthechuck(1)lightlywitha plastictippedhammer

atthetopofchuck,untilthechuckreleases.

NOTE:Placeonehandbelowthechucktocatchitwhen

it fallsout.

Fig. Z

To avoid injury from an accidental start, ALWAYS make

sure the switch is in the "OFF" position, the switch key is

removed, and the plug is not connected to the power

source outlet before removing or installing the chuck.

BASIC OPERATnON INSTRUCTIONS

To get the best results and minimize the likelihood of

personal injury, follow these instructions for operating your

drill press.

For your own safety, atways observe the safety

INSTRUCTIONS listed here and on pages 3, 4, and 5

of the instruction manual.

YOUR PROTECTION

To avoid being pulled into the power toot, do not wear

loose clothing, gloves, neckties, or jewelry. Always tie

back long hair.

1. If any part of your drill press is missing, malfunctioning,

damaged or broken, stop operation immediately until

that part is properly repaired or replaced.

2. Never place your fingers in a position where they

could contact the drill bit or other cutting too]. The

workpiece may unexpectedly shift, or your hand

could slip.

3. To avoid injury from parts thrown by the spring, follow

instructions exactly when adjusting the spring tension

of the quill.

4. To prevent the workpiece from being torn from your

hands, thrown, spun by the tool, or shattered, always

properly support your workpiece as follows:

a.

Always position BACKUP MATERIAL (used

beneath workpiece) so that it contacts the left side

of the column, or use the fence provided and

clamp to brace a smaller workpiece.

b, Whenever possible, position the WORKPIECE to

contact the left side of the column. If it is too short

or the table is tilted, use the fence provided or

clamp solidly to the table, using the table slots.

c. When using a drill press vise, always fasten it to

the table.

d. Never do any work freehand (hand-holding the

workpiece rather than supporting it on the table),

except when polishing.

e. Securely lock the head and table support to the

column, and the table to the table support, before

operating the drill press.

f. Never move the head or the table while the tool

is running.

g. Before starting an operation, jog the motor switch

to make sure the drill or other cutting tool does

not wobble or cause vibration.

h. tf a workpiece overhangs the table so it will fall

or tip if not held, clamp it to the table or provide

au.'kiliary support.

i. Use the fence provided or other fixtures for

unusual operations to adequately hold, guide,

and position workpiece.

j. Use the SPINDLE SPEED recommended for the

specific operation and workpiece material. Check

the panel on the inside pulley cover or the chart

below for drilling speed information.

For accessories, refer to the instructions provided

with each accessory.

5. Never climb on the drill press table, it could break or

pull the entire drill press down on you.

6. Turn the motor switch "OFF", and put away the switch

key when leaving the drill press.

7. To avoid injury from thrown work or tool contact, do

not perform layout, assembly, or set up work on the

table while the cutting tool is rotating.

DRILUNG SPEED TABLE (rpm)

Material

Wood Alum.,Zinc,Brass iron,Steel

3600 3600 3600

DrillBit

Diam.

(Inches)

1/16

1/8

3/I 6

1/4

5/16

3/8

1/2

2610

2610

1600

1600

880

680

26!0 540

t 8

ii

i

I

,

[

:!

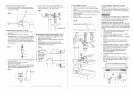

POSITIONING THE TABLE AND WORKPiECE

(FIGURE AA and IBB)

1. Lock the table (!) to the column (2) at a position so

the tip of the drill bit (3) is just above the top of the

workpiece (4).

2. ALWAYS place a BACK-UP MATERIAL (scrap wood)

on the table beneath the workpiece. This will prevent

splintering or heavy burring on the underside of the

workpiece. To keep the back-up material from spinning

out of control, it MUST contact the LEFT side of the

column.

To prevent the workpiece or backup material from being

torn from your hands while drilling, you MUST position it

against the teft side of the column. If the workpiece or

the backup material is not long enough to reach the

column use the fence provided with the drill press to

brace the workpiece., or clamp it to the tableo Failure to

do this could result in personal injury.

Fig. AA

i

3. For small pieces that cannot be clamped to the table,

use a drill press vise (optional accessory).

The drill press vise MUST be clamped or botted to the

table to avoid injury from a spinning workpiece, or

damaged vise or bit parts.

Remove the drill press fence when it interferes with other

driti press accessories.

Fig. BE}

HOLDING A DRiLMNG LOCATION

1. Using a Centerpunch or sharp nail, make an

indentation in the workpiece where YoUwant the hole.

2. Using the feed handles, bring the drill down to align

with the indentation before turning the drill "ON".

TILTING THE TABLE (FIGURE CC}

NOTE: The table and support (1) has a predrilled hole

with a locking pin inserted for locking the table into a

predetermined 0° horizontal position.

1, To use the table in a bevel (tilted) position; TIGHTEN

the nut (2) on the locking pin clockwise to RELEASE

it from the table support.

2. Loosen the large hex head bevel Jocking bott (3).

To prevent injury, be sure tO hold the table & table arm

assembly, So it will not swivel or tilt.

Fig. CC

1

3. Tilt the table, aligning the desired angle measurement

to the zero line opposite the scale (4). Tighten the bevel

locking bolt.

4. To return the table to its original position, loosen the

bevel locking bolt (3). Realign the bevel scale (4) to

the 0° position,

5. Loosen the nut (2) on the locking pin to the OUTSIDE

END OF THREADS. Gently tap the locking pin until it

is seated in the hole. Finger tighten the nut.

To avoid injury from spinning work or toot breakage, always

clamp workpiece and backup material securely to the

table before operating the drill press with the table tilted.

FEEDING

t. Pull down the feed handles with only enough effort to

allow the driJi bit to cut.

2. Feeding too slowly might cause the drill bit to burn.

Feeding too rapidly might stop the motor, cause the

belt or drill to slip, or tear the workpiece loose and

break the drill bit.

3. When drilling metal, it may be necessary to lubricate

the drill bit tip with motor oil, to prevent burning the tip.

19