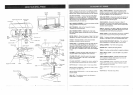

_NSTALMNG FEED HANDLES (FIG. H)

1. Locate three feed handles in the loose parts bag.

2. Screw the feed handles (1) into the threaded holes (2)

in the hub (3). Tighten.

INSTALLING THE CHUCK (FIG. t, J and K)

t. Clean out the tapered hote in the chuck (1) with a

clean cloth.

2. Clean tapered surfaces on the spindle (2).

CAUTION: Make sure there are no foreign particles

sticking to the surfaces. The slightest piece of dirt on

any of these surfaces will prevent the chuck from

seating properly. This will cause the drill chuck and

bit to wobble. If tapered hole is extremely dirty, use a

cleaning solvent.

Fig.I

2

3. Lower the spindle (2) by turning the feed handles (3)

counterclockwise.

4. Push the chuck up onto the spindle (2).

Tap gently to ensure seat.

5. Open the jaws of the chuck (t) by rotating the chuck

sleeve clockwise. To prevent damage, make sure the

jaws are completely receded into the chuck.

Fig. J

2 --

ti

3

,

Using a rubber maltet, plastic-tipped hammer, or a

block of wood and a hammer, firmly tap the chuck

upward into position on the spindle shaft.

Fig, K

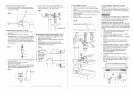

MOUNTING DRILL PRESSTO WORK SURFACE (FIG. L)

1. If mounting the drill press to a workbench, a solid

wood bench is preferred over a plywood board, to

reduce noise and vibration.

2. Holes should be pre-drilled through the supporting

surface.

3. The hardware to mount this drill press is NOT

supplied with the tool. The hardware as shown in

the illustration should be used:

Fig. L

1. Drill press base

2. Boft

I

3. Flat washer i

4. Rubber washer

5. Worksurface

6. Flat washer |

7. Lockwasher !

Hex nut __

8.9. Jam nut _\

\

"1

5

I

Ii

It

i i .......................

tt

6 _

E

E

FENCE ASSEMBLY (F_G°M}

t. Determine the desired location for the fence (.1).

2. Aiign the mounting holes of the fence over the table

top slots.

3. Place a washer (2) on the threaded end of the knob (3).

Insert the knob through the mounting hole of the fence

and the table slot.

4. Place a washer and wing nut (4) on the knob from '

under the table.

5. Repeat for the other knob and tighten.

Fig. M

ADJ UST 'V ENT INSTRUCTIONS

CAUTION: All the adjustments for the operation of the

drill press have been completed at the factory. Due to

normal wear and use, some occasional readjustments

may be necessary.

To avoid injury from an accidental start, ALWAYS make

sure the switch is in the "OFF" position, the switch key is

removed, and the plug is not connected to the power

source outlet before making belt adjustments.

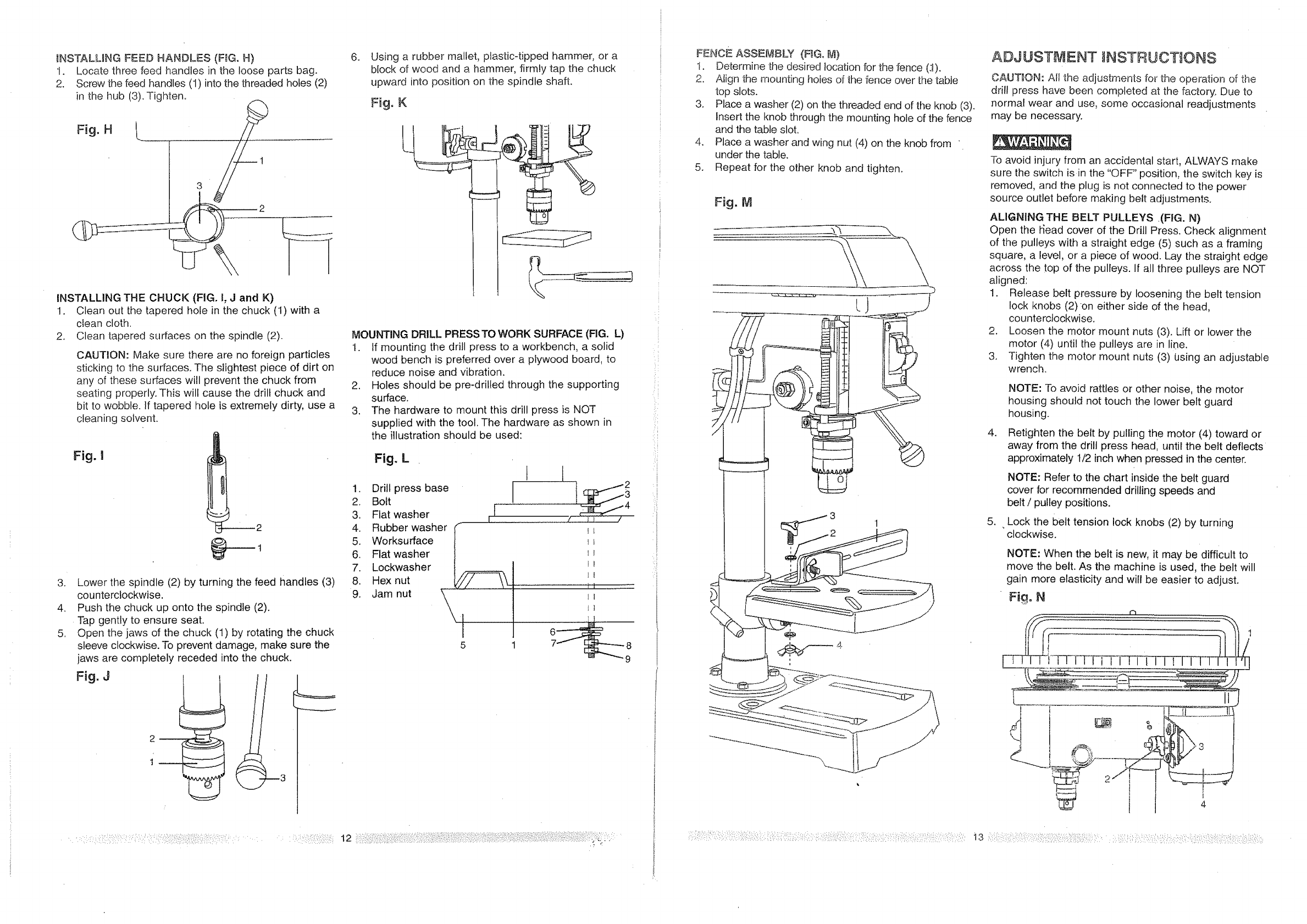

ALIGNING THE BELT PULLEYS ,(FIG. N)

Open the t_ead cover of the Drill Press. Check alignment

of the pulleys with a straight edge (5) such as a framing

square, a level, or a piece of wood. Lay the straight edge

across the top of the pulleys. If all three pulleys are NOT

aligned:

1. Release belt pressure by loosening the belt tension

lock knobs (2)on either side of the head,

counterc!ockwise.

2. Loosen the motor mount nuts (3). Lift or lower the

motor (4) until the pulleys are in line.

3. Tighten the motor mount nuts (3) t_sing an adjustable

wrench.

4,

,

NOTE: To avoid rattles or other noise, the motor

housing should not touch the lower belt guard

housing.

Retighten the belt by pulling the motor (4) toward or

away from the drill press head, until the belt deflects

approximately t/2 inch when pressed in the center.

NOTE: Refer to the chart inside the bett guard

cover for recommended drilling speeds and

belt / pulley positions.

. Lock the belt tension lock knobs (2) by turning

clockwise.

NOTE: When the belt is new, it may be difficult to

move the belt. As the machine is used, the belt will

gain more elasticity and will be easier to adjust.

Fig. N

¢h

,,_ ........ >s

........... i 3 :::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::