8ASmC SAW OPERATmONS

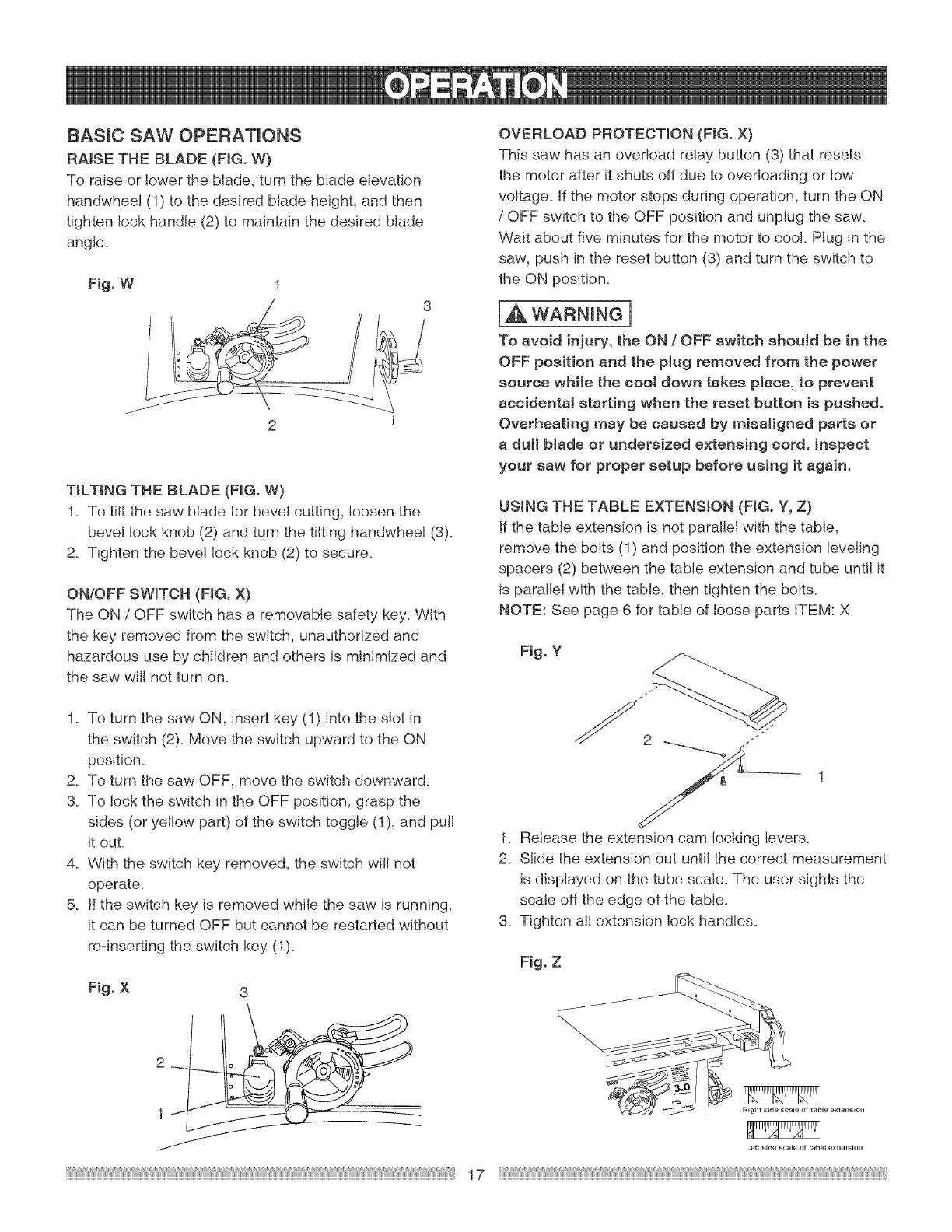

RAISE THE BLADE (FIG. W)

To raise or lower the blade, turn the blade elevation

handwheel (1) to the desired blade height, and then

tighten lock handle (2) to maintain the desired blade

angle.

Fig. W

2

TILTING THE BLADE (FIG. W)

1. To tilt the saw blade for bevel cutting, loosen the

bevel lock knob (2) and turn the tilting handwheel (3).

2. Tighten the bevel Iock knob (2) to secure.

ON/OFF SWITCH (FIG. X)

The ON / OFF switch has a removable safety key. With

the key removed from the switch, unauthorized and

hazardous use by children and others is minimized and

the saw wil! not turn on.

1. To turn the saw ON, insert key (1) into the slot in

the switch (2). Move the switch upward to the ON

position.

2. To turn the saw OFF, move the switch downward.

3. To lock the switch in the OFF position, grasp the

sides (or yel!ow part) of the switch toggle (1), and pul!

it out.

4. With the switch key removed, the switch will not

operate.

5. If the switch key is removed while the saw is running,

it can be turned OFF but cannot be restarted without

re-inserting the switch key (1).

Fig. X

3

lJ

/

17

OVERLOAD PROTECTION (FIG. X)

This saw has an overload relay button (3) that resets

the motor after it shuts off due to overloading or low

voltage. If the motor stops during operation, turn the ON

/ OFF switch to the OFF position and unplug the saw.

Wait about five minutes for the motor to coo!. Plug in the

saw, push in the reset button (3) and turn the switch to

the ON position.

[,_. WARNING]

To avoid injury, the ON t OFF switch should be in the

OFF position and the plug removed from the power

source while the coot down takes place, to prevent

accidental starting when the reset button is pushed.

Overheating may be caused by misaligned parts or

a dull blade or undersized extensing cord. inspect

your saw for proper setup before using it again.

USING THE TABLE EXTENSION (FIG. Y, Z}

If the table extension is not paraflei with the table,

remove the bolts (1) and position the extension leveling

spacers (2) between the table extension and tube unti! it

is parallel with the table, then tighten the bolts.

NOTE: See page 6 for table of loose parts iTEM: X

Fig. Y

1. Release the extension cam locking levers.

2. Slide the extension out until the correct measurement

is displayed on the tube scale. The user sights the

scale off the edge of the table.

3. Tighten all extension lock handles.

Fig. Z