8

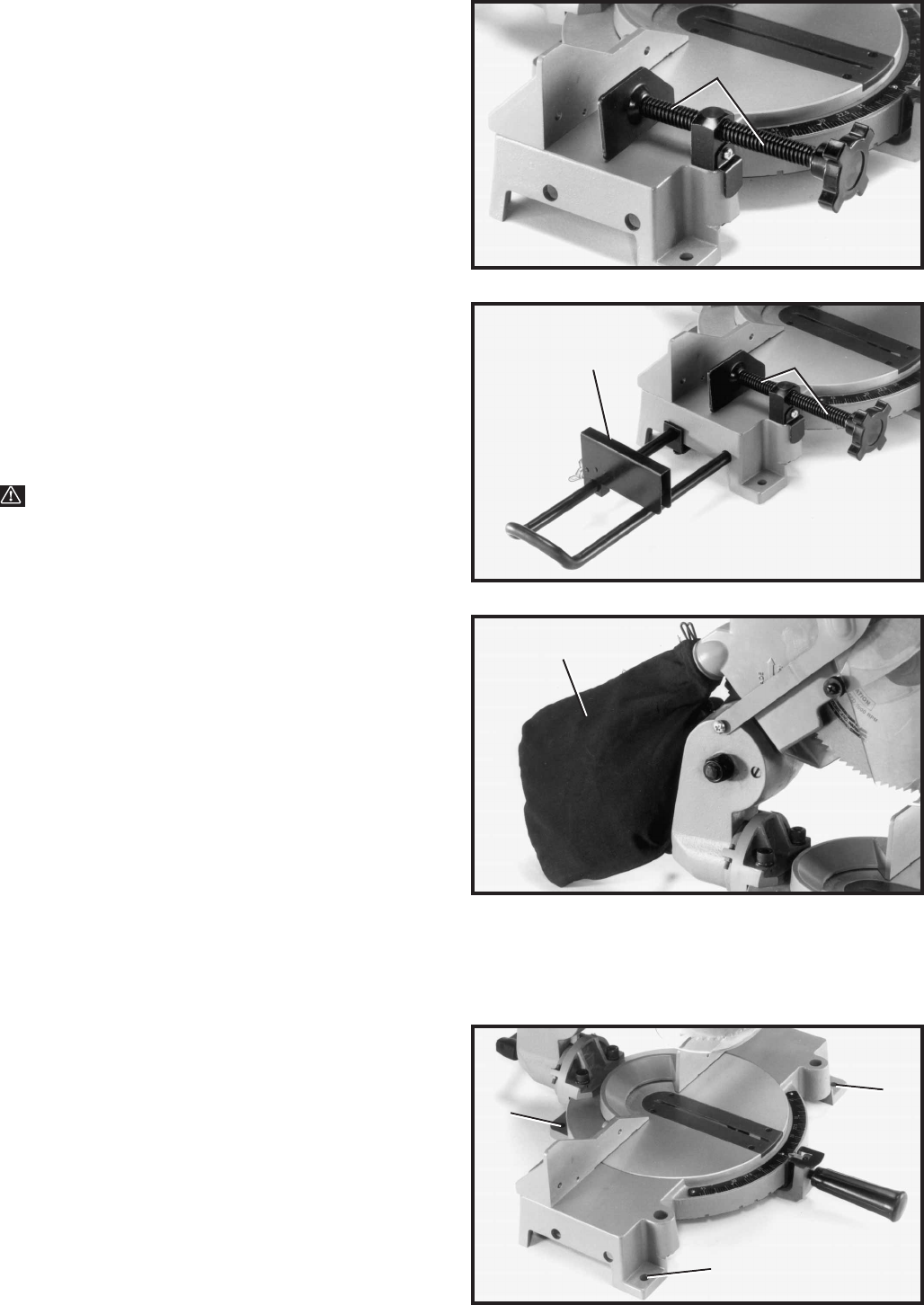

Fig. 12

Fig. 11

Fig. 10

Fig. 9

ASSEMBLING ACCESSORY

WORK CLAMP TO SAW

1. The work clamp (A) Fig. 9, can be used on either the

right or left side of the saw base. Insert post of work

clamp into the hole located on the front of the saw base,

as shown. Work clamp 36-221 is available as a accesso-

ry. (See ASSESSORIES section)

2. IMPORTANT: The purpose of the work clamp (A)

Fig. 10, is to clamp material against the fence. When the

work clamp (A) is used in conjunction with the stock stop

(B), the work clamp (A) and stock stop (B) should

ALWAYS be used on the same side of the saw blade.

This is important as it prevents the free end of the work-

piece from binding between the blade and the stock stop

(B).

3. WARNING: Keep hands out of path of saw

blade. If the workpiece you are cutting would cause

your hand to be within 4 inches of the saw blade, the

workpiece should be clamped in place before making

cut.

ASSEMBLING DUST BAG

1. Assemble the dust bag (A) Fig. 11, to dust spout on

rear of guard assembly, as shown.

Before operating your compound miter saw make sure it

is firmly mounted to a workbench or other supporting sur-

face. Four holes are provided, three of which are shown

at (A) Fig. 12, for fastening the saw to a supporting sur-

face.

When frequently moving the saw from place to place we

suggest that the saw be mounted to a 3/4" piece of

plywood. The saw can then be easily moved and the ply-

wood clamped to the supporting surface using “C”

clamps.

FASTENING COMPOUND MITER SAW

TO SUPPORTING SURFACE

A

B

A

A

A

A

A