9

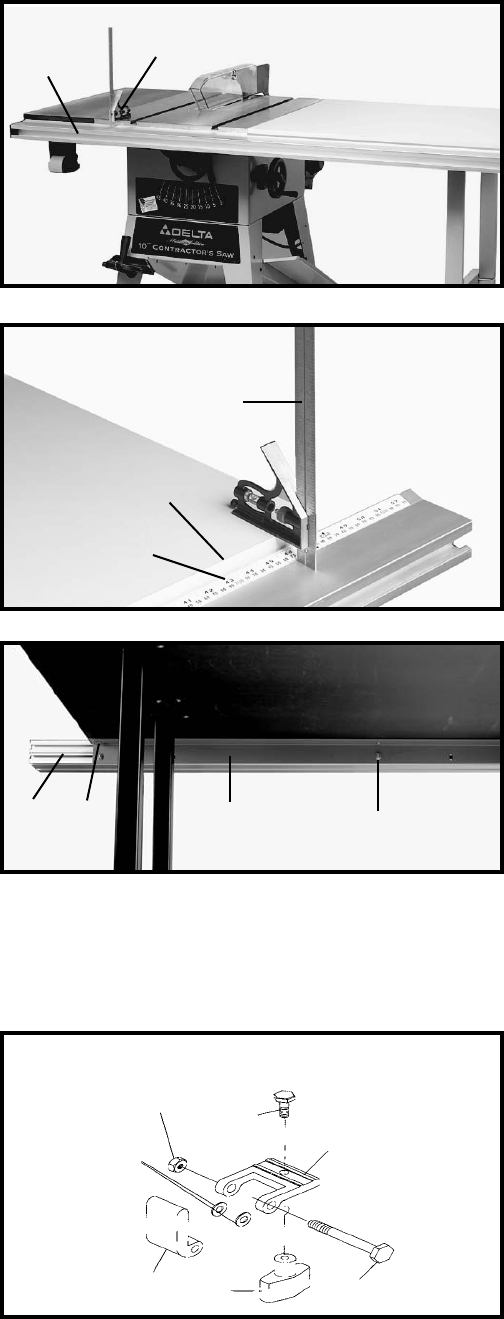

6. Slide the guide rail along until the “0” on the Unifence

scale is aligned with the right edge of the saw table. Snug

the hex nuts on the saw and extension table but do not

tighten at this time.

7. Adjust the guide rail (C) Fig. 25, parallel with the saw

table surface. Place a square (H) on the saw table at both

the left and right front ends of the table, with the rule of

the square against the flat surface on top of the guide rail.

The guide rail (C) Fig. 25, can be adjusted up or down at

either end. After you are certain the guide rail is parallel

with the table surface, firmly tighten the two hex nuts that

fasten the guide rail to the table. NOTE: If a bolt was

inserted through a sheet metal extension wing on the

left side of the saw, tighten that nut also.

8. Move the square (H) Fig. 26, to the end of the

Unifence table and check to make certain the same

distance is maintained from the top surface of the

extension table (K) to the top surface of the guide rail (C).

Move the front table support (L) Fig. 27, against the guide

rail (C), and tighten the 1/4-20 nut (M). Tighten two wood

screws, one of which is shown at (N) Fig. 27, that fasten

the Unifence table to the guide rail.

Fig. 25

Fig. 26

Fig. 27

ASSEMBLING RAIL STOP

1. Insert 1/4-20x2" bolt (A) through hole into one side of

bracket (B) Fig. 28.

2. Place one washer (C), on bolt (A), and slide bolt

through flip stop (D) Fig. 28.

3. Place the other washer (C), on bolt (A), and slide bolt

(A) through other side of bracket (B) Fig. 28.

4. Screw nut (E) onto bolt (A) and tighten.

5. Insert bolt (F) through bracket (B) as shown and

screw knob (G) onto bolt (F) approximately 3 complete

turns. Fig. 28.

6. Attach rail stop to unifence as shown in Fig. 30.

7. Using a rubber mallet (P) Fig. 29, or a hammer and a

block of wood, gently tap end cap (R) into both ends of

the guide rail. NOTE: To avoid damage to the guide rail,

DO NOT use a metal hammer directly against the guide

rail.

Fig. 28

E

C

F

B

A

G

D

C

K

H

M

L

C

C

H

N