17

Before starting the machine, see that all adjustments are properly made and the guards are in place. Turn the upper

wheel by hand to make sure that everything is correct BEFORE turning on the power.

Keep the top guide within 1/8" of the work piece at all times. Do not force the material against the blade. Light pressure

on the work piece will produce a smoother cut, and prevent excess friction, heating, and hardening of the blade.

KEEP THE SAW BLADE SHARP. Very little forward pressure is required for normal cutting. Keep the workpiece moving

at a slow and consistent rate against the blade to ensure a smooth and accurate cut.

Avoid twisting the blade by trying to turn sharp corners. Remember, you must saw around corners.

Fig. 39

CUTTING CURVES

CUT HAZARD: Keep hands away from blade.

When cutting curves, turn the stock carefully so that the blade follows without twisting. If a curve is so abrupt that it is

necessary to repeatedly back up and cut a new kerf, a narrower blade, a blade with more set, or additional relief cuts

Fig. 39, may be necessary to allow the blade to cut more efficiently. The more set a blade has, the easier it will allow

the stock to be turned, but the cut is usually rougher than where a medium amount of set is used.

When withdrawing the piece being cut, changing the cut, or for any other reason, be careful not to accidentally draw the

blade off the wheels. In most cases, it is easier and safer to turn the stock and saw out through the waste material, rather

than try to withdraw the stock from the blade.

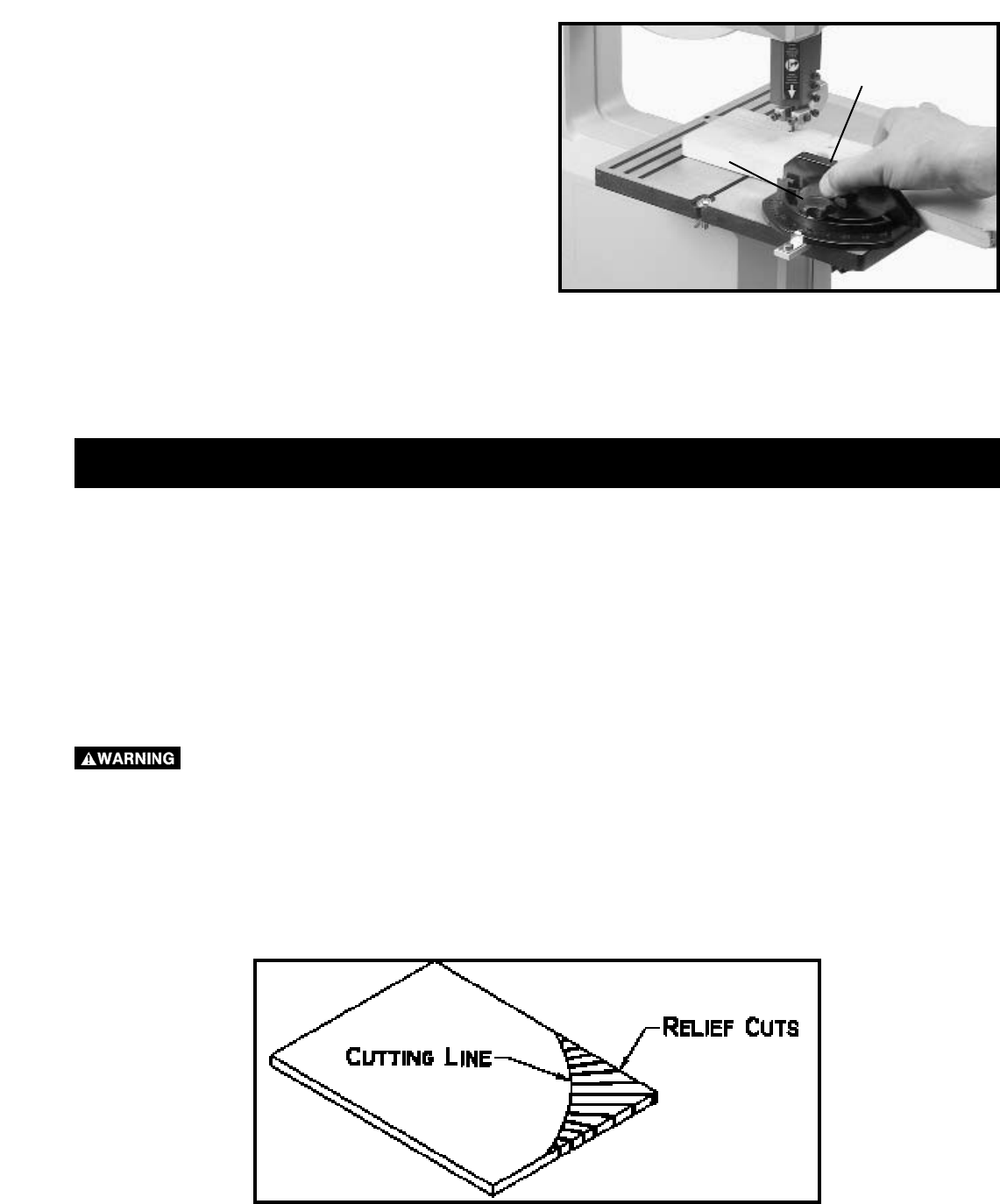

Fig. 38 illustrates a typical cross-cutting operation using

the accessory miter gauge. Notice how the upper blade

guide assembly is set slightly above the work surface.

A

B

Fig. 38

OPERATING THE BAND SAW

MITER GUAGE (OPTIONAL)

Some Shopmaster Band Saws come with a miter gauge.

If your machine has a miter gauge, you can adjust it up

to 45 degrees, right and left. Loosen the lock knob (A),

rotate the miter gauge body (B) and tighten the lock knob

(A).