OPERATION

Operator Controls

The unloader valve for the operation of the gasoline

compressor outfit is located between the compressor

pump and gasoline engine. The air discharge valve

can be located on the end of the air tank. The safety

valve and pressure gauge are attached to the tank

below the unloader. See page 7.

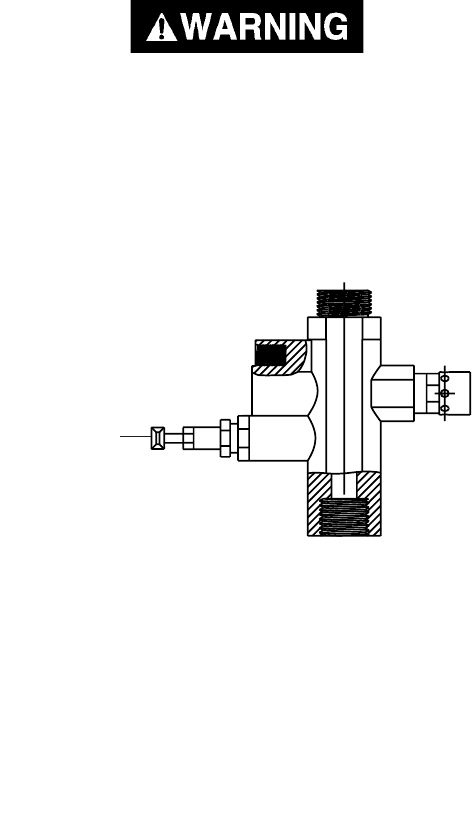

Unloader Valve

Pressure loads beyond the design limits

may cause tank rupture or explosion. Do

not attempt to adjust, remove, or defeat

the unloader valve, or change and modify

any pressure control device. If replace-

ment is necessary, the same rated valve

must be used.

Figure 6. Unloader Valve

The unloader valve, Figure 6, is controlled by tank pres-

sure. Compressors with unloaders run continuously

and maintain air pressure within set limits. At maxi-

mum tank pressure the unloader valve opens and the

compressed air is exhausted to atmosphere. This

prevents the compressor from continually building more

pressure if air is not needed. When the tank pressure

drops to a predetermined minimum pressure, the

unloader valve closes and the compressor again builds

up the tank pressure. Pressure continues to build un-

til maximum tank pressure is achieved. The cycle

then repeats itself.

The unloader is used because frequent start-ups and

stops are impractical with a gasoline engine. The

unloader valve is preset at the factory. Never attempt

to make adjustments to the unloader valve.

The toggle lever on the front of the unloader valve should

be pulled out or in the horizontal position when start-

ing up the compressor. This prevents the compressor

from starting under load. Once the engine has reached

full throttle, the lever should be pushed to the side,

returning it to its original position to allow the com-

pressor pump to build pressure in the air tank.

PAGE 11

Toggle

Lever