PAGE 13

4. Check the engine fuel tank level. Add fuel if

necessary.

Before starting the compressor outfit, check the

following:

5. Close the air discharge valve.

6. Set the toggle lever of the unloader valve in

the vertical position to relieve compressor

head pressure.

7. Move the control lever or choke lever to the

CHOKE position.

8. Turn the engine lever or key switch to the

ON position.

NOTE

If the engine is warm or the air tem-

perature is high, move the control

lever or choke lever away from the

CHOKE position as soon as the engine

starts.

9. Start the compressor outfit by pulling the

starter handle or by depressing the starter

button. Return the toggle lever on the unloader

valve to the horizontal position and allow

outfit run for 10 minutes without building any

pressure. Check that the unloader exhausts

air at maximum tank pressure.

If these break-in procedures are not

followed, premature pump failure may

result and void your warranty.

10.Check the following:

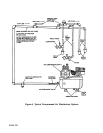

a. Make sure all controls are operating

correctly. Refer to the "Operator Controls"

section of this manual. A separate

gasoline engine instruction manual is

provided detailing engine operation.

b. Check all air lines, fittings and pipes for

leaks. Even minor leaks can cause the

compressor to overwork resulting in

premature breakdown or unsatisfactory

performance.

3. Periodically check the compressor outfit during

the first few days of operation to make sure

the compressor outfit is running smoothly and

all controls are operating properly.

NOTE

After the compressor has been in

operation for 2 to 3 hours, tighten the

compressor head bolts.

Torque two stage compressor head

bolts to 35 foot-pounds using a criss-

cross pattern when tightening.

BREAK-IN PROCEDURES

Perform steps 1-8 of the Daily Startup Procedures.

Open the air discharge valve.

DAILY STARTUP PROCEDURES

Perform the following checks before starting the

compressor outfit.

1. Ensure that nothing is blocking the belt

guard air openings.

2. Pull the ring on the safety valve to make

sure the valve moves freely and smoothly.

3. Check the engine and compressor oil levels.

Add oil if necessary.

Gasoline is extremely flammable and

explosive. Refuel in a well ventilated

area with engine stopped. Allow engine

to cool before refueling.

Do not smoke or allow flames or sparks in

the area where the engine is refueled or

where gasoline is stored.

Do not overfill the tank and make sure

the filler cap is securely closed after

refueling. Be careful not to spill fuel

when refueling. Fuel vapor or spilled

fuel may ignite. If any fuel is spilled,

make sure the area is dry before

starting the engine.