PAGE 6

You have purchased a complete compressor outfit con-

sisting of an air compressor, ASME approved air tank,

gasoline engine, and associated controls and instru-

ments. The compressor outfit you have selected is a

two stage stationary outfit.

Your new compressor can be used for operating paint

sprayers, air tools, grease guns, air brushes, caulking

guns, and sand blasters, spraying weed killer and

insecticides, etc. An air pressure regulator may be

necessary for some of these

The gasoline engine uses a pulley and drive belt to

drive the compressor flywheel. The flywheel turns the

compressor crankshaft causing the up and down move-

ment of the pistons in the cylinder; this up and down

movement draws and compresses the air.

On the down stroke of the piston, air is drawn in through

the air intake. The exhaust valves remain closed. On

the up stroke of the piston, both the valves are closed

and air is compressed in the cylinder. As pressure

builds in the cylinder the exhaust valve opens and the

compressed air is forced out of the cylinder through

the check valve and into the air tank. This process

continues until the air pressure reaches maximum tank

pressure.

Working air pressure becomes available when the com-

pressor has raised the tank pressure above that re-

quired at the air discharge valve. The air intake must

be kept clear of all obstructions which could interfere

with air delivery to the compressor.

All gasoline compressor outfits are continuously run-

ning outfits controlled by tank pressure. At maximum

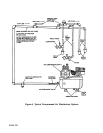

applications. Refer to Figure 1 for a photograph of

the compressor and to identify the major components

of the compressor.

A regularly scheduled program of preventive mainte-

nance is necessary to insure the long life that has been

designed into your DeVilbiss compressor outfit. This

instruction manual, along with regular maintenance

will maintain your compressor outfit in good working

order. Before operating or performing any maintenance

on your outfit, refer to these publications.

tank pressure the unloader valve exhausts air to at-

mosphere (blowoff); tank pressure closes the check

valve retaining air pressure inside the tank. When tank

pressure drops to a pre-determined pressure, the

unloader valve closes, and air pressure opens the

check valve allowing compressed air into the tank. As

maximum tank pressure is reached, if the unloader

valve malfunctions and compressed air is not ex-

hausted at or near its blowoff setting, the air tank safety

valve will protect the air tank against high pressure by

popping at its factory set pressure. The safety valve

popping pressure is slightly higher than the unloader

valve blowoff pressure.

This compressor outfit is equipped with a gas saving

throttle control device. When maximum tank pressure

is reached and the unloader valve opens the throttle

control is also activated, The throttle control holds the

engine at a factory set idling speed until air pressure

in the tank drops to reset or minimum tank pressure.

At reset pressure when the unloader valve closes the

throttle control is reactivated and the engine acceler-

ates to full throttle.

GENERAL INFORMATION

DESCRIPTION OF OPERATION