DANGER

HAZARDOUS AREA INSTALLATION

Installations near flammable liquids or in hazardous

area locations must be carefully evaluated by qualified

on site safety personnel. This sensor is not Intrinsically

Safe or Explosion Proof.

To secure and maintain an intrinsically safe installa-

tion, the certified safety barrier, transmitter, and sen-

sor combi nation must be used. The installation sys-

tem must comply with the governing approval

agency (FM, CSA or BASEEFA/CENELEC) haz-

ardous area classification requirements. Consult your

analyzer/transmitter instruc tion manual for details.

Proper installation, operation and servicing of this

sensor in a Hazardous Area Instal lation is entirely

the responsibility of the user.

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures, and tests its products to

meet many national and international standards. Because these instru-

ments are sophisticated technical products, you must properly install,

use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions must be adhered to and

integrated into your safety program when installing, using, and main-

taining Rosemount Analytical products. Failure to follow the proper

instructions may cause any one of the following situations to occur: Loss

of life; personal injury; property damage; damage to this instrument; and

warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the

product. If this Instruction Manual is not the correct manual, telephone

1-800-654-7768 and the requested manual will be provided. Save this

Instruction Manual for future reference.

• If you do not understand any of the instructions, contact your

Rosemount representative for clarification.

• Follow all warnings, cautions, and instructions marked on and

supplied with the product.

• Inform and educate your personnel in the proper installation, opera-

tion, and maintenance of the product.

• Install your equipment as specified in the Installation Instructions of

the appropriate Instruction Manual and per applicable local and

national codes. Connect all products to the proper electrical and

pressure sources.

• To ensure proper performance, use qualified personnel to install, oper-

ate, update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people

use replacement parts specified by Rosemount. Unauthorized parts

and procedures can affect the product’s performance and place the

safe operation of your process at risk. Look alike substitutions may

result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are

in place, except while maintenance is being performed by qualified

persons, to prevent electrical shock and personal injury.

About This Document

This manual contains instructions for installation and operation of the Model 396R & 396RVP TUpH

Retractable pH/ORP Sensors. The following list provides notes concerning all revisions of this document.

Rev. Level Date Notes

A 1/96-1/01 This is the initial release of the product manual. The manual has been reformatted to reflect the

Emerson documentation style and updated to reflect any changes in the product offering.

B 7/02 Revised multiple drawings.

C 8/02 Added drawing #40105549, rev. D.

D 4/03 Revised drawing #40396R21/22 on page 18.

E 8/03 Added Silcore information.

F 9/04 Updated ordering info and added/revised wiring drawings.

G 1/05 Delete obsolete options.

H 1/07 Miscellaneous revisions.

I 11/10 Removed mention of patents and updated dnv logo.

J 2/11 Added ATEX directive and updated caution boxes per ANSI standard.

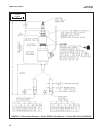

RETRACTABLE SENSORS

Retractable sensors must not be inserted nor

retracted when process pressures are in excess

of 64 psig (542kPa) for option 21 or 35 psig

(343 kPa) for option 25.

The wetted sensor materials may not be com-

patible with process com position and operating

conditions.

Application compat ibility is entirely

the

responsibility of the user.

CAUTION

SENSOR/PROCESS APPLICATION COMPATIBILITY

WARNING

ATEX DIRECTIVE

Special Conditions for safe use

1. All pH/ORP sensors have a plastic enclosure which must only be cleaned with a damp cloth to avoid the danger due

to a build up of an electrostatic charge.

2. All pH/ORP sensor Models are intended to be in contact with the process fluid and may not meet the 500V r.m.s. a.c.

test to earth. This must be taken into consideration at installation.