The LTM-300 is an electronic field instrument, suitable for installation

in hazardous and non-hazardous industrial areas. Testing and

certification has been obtained from different agencies for installation

in specific areas.

This instrument is a two wire, loop powered smart transmitter, designed

to measure and transmit an analog 4-20 mA signal and two digital outputs

(optional) proportional to liquid level in a tank. The optional temperature

output is configured via the HART communicator. Interface is auto-detect.

Note: Both floats have to be present for auto-detection. The complete

assembly includes a dual compartment explosion proof enclosure, and

attached sensor tube.

Optional Features of the LTM-300 include:

• Second digital output proportional to an interface level (requires

a second float of different specific gravity)

• Digital temperature output gives the liquid temperature and is

typically used for display and/or calculation of mass.

• A variety of lengths and wetted materials to accommodate many

different applications.

• Mass or Volume Information

Product Serial Number

Magtech assigns a unique serial number for each unit. The first two digits

indicate the month of production followed by two digits, indicating the

year of production. For example, serial number 0606 / 1234 describes a

unit manufactured in June of 2006 with a serial number 1234.

In its simplest configuration, a single-purpose float rides up and down

the sensor tube, totally surrounding it. A multi-purpose float may also

be used to activate the sensor, such a float being placed inside a liquid

isolation pipe, (i.e. Mag-Gage) and strategically located within a certain

longitudinal distance form the sensor tube. In either case, the float has

a somewhat lighter specific gravity than the liquid whose level is to be

measured, so that it is partially submerged at the interface of interest.

As the tank level changes, the float tracks the change and continuously

activates the sensor in the tube. The electronics in the housing process

the changing signal and update an analog 4-20 mA output. This analog

output is precisely proportional to the liquid level in the tank.

SECTION 1. Transmitter Overview

1.0 General Description

1.1 Level Transmitter

The LTM-300 may be strapped to the side of the MagTech LG series

magnetic level indicator. In such an installation, it is used as an

accessory transmitter for the visual level gage. The same float used

to activate the magnetic gage is also used to transmit a signal to the

magnetostrictive sensor of the LTM-300.

1.2 Gage Mounted Transmitter

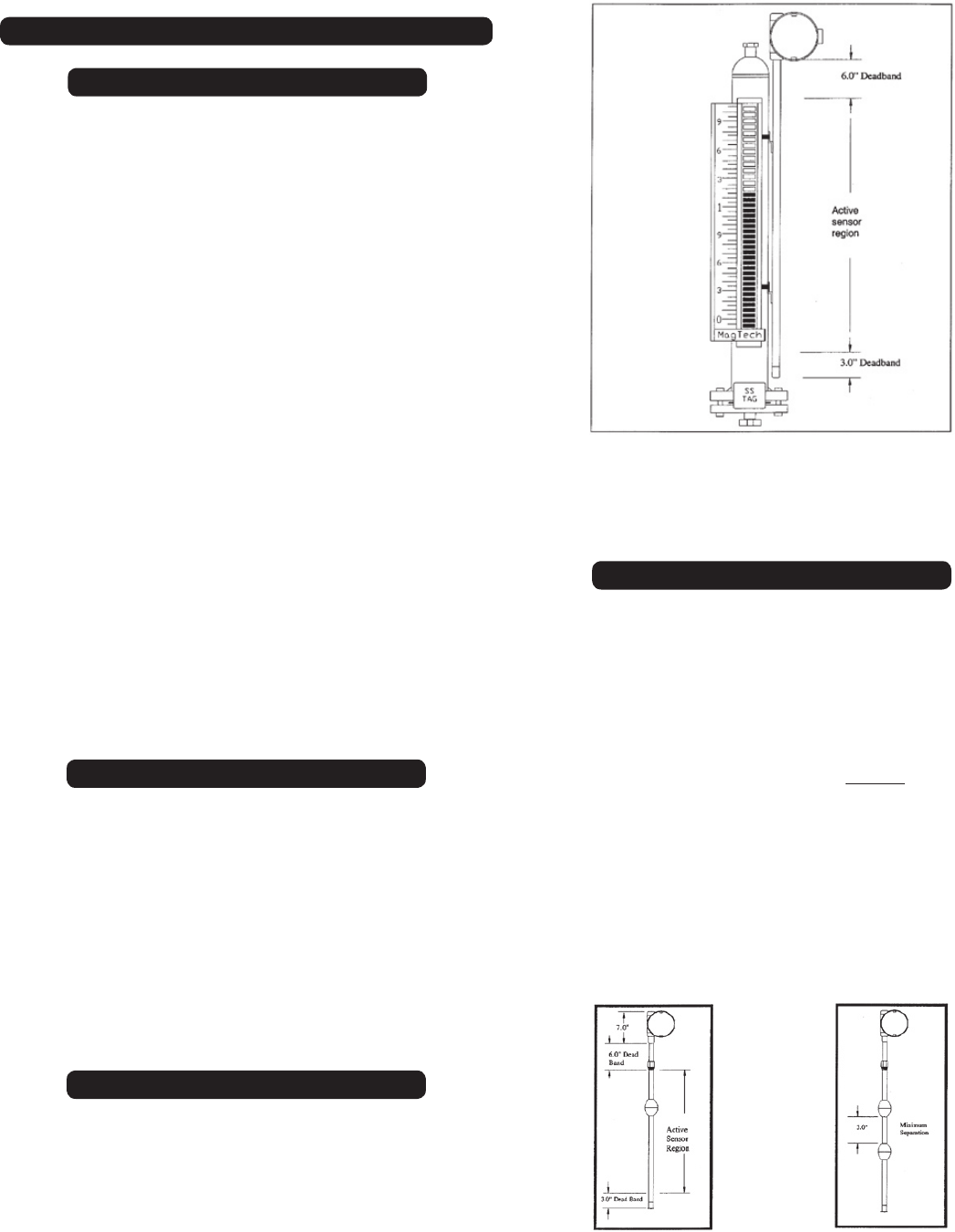

In the above right shown installations, the transmitters may be

calibrated for the same range as the visual indicator on the Mag-Gage,

or for part of the range (See Section 3).

LTM-300 Mounting Configuration

Style B & C LG Series Gage

When a companion magnetic gage is not present, the LTM-300 is

inserted into the tank with its own float around the sensor tube. A

stilling well may be optionally used inside the tank or, in case of high

temperatures; an external chamber may be the housing of the tube

and float assembly.

Note 1:

When a stilling well is used, care should be exercised when installing

the tube to center it in the chamber so that the float can freely travel the

entire length of the probe. Stilling wells are required for transmitters

over 10 feet.

Up to two floats may be used with the LTM-300. The second float

will typically sense the interface level of the heavier of the two fluids

in the tank. The specific gravity of the second float will be such that

it can be totally immersed in the lighter fluid.

Note 2:

When two floats are used, a minimum separation of about three inches

is recommended to prevent interference between floats.

1.3 Standalone Transmitter

The calibration range of the transmitter may be field stored in non-

volatile memory by using the float and push buttons. The push

buttons are located on the front panel inside the condulet. See

section on Calibration for more details

.

Single Float Transmitter

Dual Float Transmitter

1