6.4 Start-Up for Gage-Mounted

LTM Transmitters

If the transmitter does not appear to calibrate properly, or has an erratic

output, check the deadband of the sensor tube and ensure that the

float is within the active region of the probe. The active region of the

sensor tube is typically marked with 20mA and 4mA stickers when

the unit is calibrated before shipment.

If the output is still erratic, try disconnecting the power momentarily

by unplugging and re-plugging-in the terminals. If a glitch was stored

in RAM memory, this will generally clear it.

It is possible for the LTM-300 to be magnetically biased or have

residual magnetic energy stored along the length of the waveguide.

These magnetic anomalies can interfere with the signal-to-noise ratio

and the stability of the output signal itself.

If this appears to be the case, a gage float magnet (or any magnet

available) may be run along the length of the sensor tube, past the

head of the transmitter, in an even motion and without stopping. This

will usually clear all such magnetic anomalies.

The LTM-300 is designed to operate with a supply voltage of 15-36 vdc

(at 20 mA) across its terminals without affecting the mA signal. The most

common loop supply used is 24vdc.

It is found sometimes that additional resistance in the loop is necessary,

either in the form of a second load resistor or higher resistance safety

barrier. This will appear to limit the maximum output of the transmitter

to below 20 mA. The transmitter will generally perform correctly up to

this point. To resolve this problem, the voltage of the loop supply must be

increased somewhat. Even a slight increase by one volt may be sufficient

and many supplies have such an adjustment.

All connections must be checked for improper wiring or polarity before

power is applied. The LTM-300 has series diodes preventing the

reverse polarity from entering and damaging the circuitry. If power is

applied and the signal is 0.0 mA, chances are good that the polarity

is reversed.

SECTION 6. Troubleshooting and Maintenance

6.0 Diagnostics are Via HART

6.1 Calibration Problems

6.2 Magnetic Interface

6.3 Troubleshooting Power Supply Problems

Never move a magnet in a perpendicular motion from along

the sensor tube. This will always leave a residual field in the

waveguide which will cause the transmitter to give an erratic

output

Gage and Transmitter Installation

1. Visually inspect Mag-Gage and transmitter installation to

insure transmitter is positioned with the 4 mA and 20 mA

labels directly adjacent to the process connections. Make sure

transmitter is securely clamped and parallel to gage chamber.

2. Remove bottom flange and install float. Each float is clearly

tagged with serial number of the Mag-Gage and process

parameters. Top of float is clearly marked “TOP” to insure float

is in right side up.

3. Inspect bottom flange for proper gasket and spring. This

spring protects float and keeps it from dropping below the

bottom process connection. To determine proper spring length

measure “A” dimension of gage. This is the length from the

center of the bottom process connection to face of the bottom

drain flange. Length of spring should be

(“A” DIMENSION) (-) Minus (Float Length + 2 inches)

EXAMPLE: “A” Dimension is 14”, Float length is 12”, + 2” = 4”

Spring Length.

14 – 12 + 2 = 4” spring

4. Float is properly installed if the bottom 2-3 flippers on gage

indicator have flipped.

Transmitter Check-out and Calibration

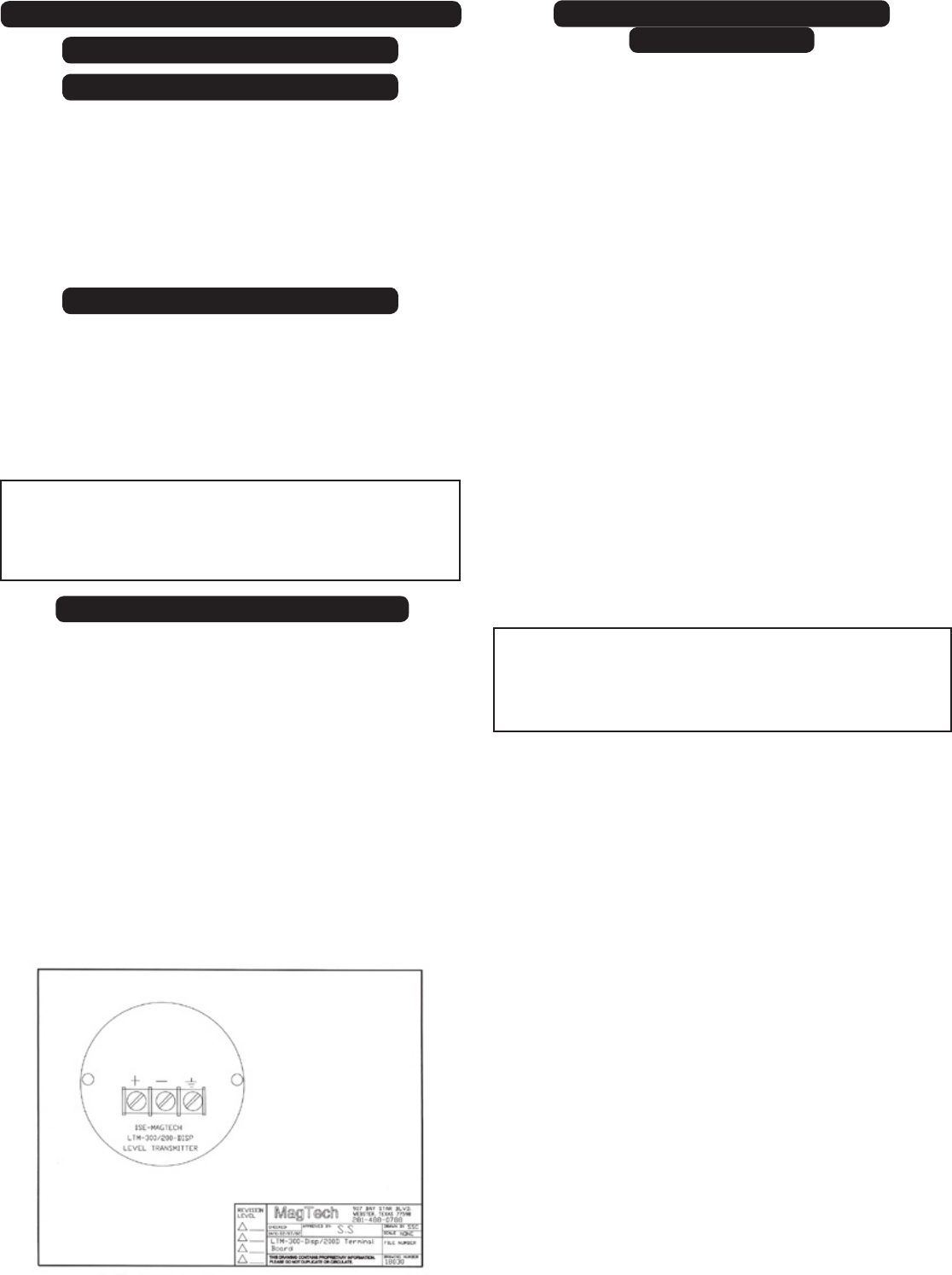

NOTE: The LTM Series Transmitters are 24VDC Loop powered (2-

wire) and require a minimum of 15 Volts at 20 mA.

1. Using a HART compatible loop calibrator, connect the “+” terminal

on the LTM to positive lead of calibrator and the “-” terminal on the

LTM to negative lead of calibrator.

2. With float in the gage at 4mA, the output of the LTM should be

4mA. Connect the HART Communicator to the transmitter.

Upon power up, the HART Communicator should read the LRV

(lower range value) or 0 inches at 4mA.

NOTE: There is a top spring in the Mag-Gage to

protect float and prevent it from passing the top

process connection. DO NOT REMOVE EITHER

SPRING.

3. With float in the gage at 20mA, the output of the LTM should be

20mA. HART should also display URV (upper range value) or

span length in inches at 20mA.

4. To insure complete functionality of gage and transmitter, fill

the gage chamber with liquid and drain slowly to observe

transmitter and gage are tracking properly.

6

CAUTION:

TERMINAL BOARD