Configure Your Sy

stem

Configure Your

System

1. Select a Bas

e Model

Choose a PD2K base model that meets your

application’s requirements. See Models, page 3 .

Base models i

nclude components A through F shown

in the Typic

al Installation drawing on the next page.

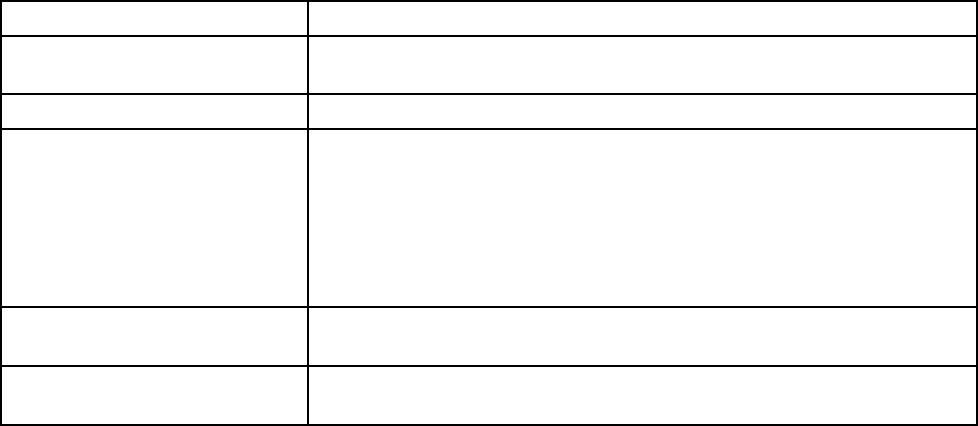

Base unit components are described in the following

table.

Component

Descriptio

n

Fluid Pump

s (A, B)

Thebasemo

dels include two fluid pumps, one for resin and one for

catalyst.

Install in the non-hazardous area.

Solvent Flow Switch (C) Confirms solvent flow to gun during purge.

Electrical Control Box (D) The electrical control box includes a barrier board, intrinsically safe

isolation board, 24 Vdc and 48 Vdc power supplies, Enhanced

Fluid Control Module, and Pump Control Modules. The Gateway

communication module, shipped separately, is installed in the electrical

control box. It accepts 90–250 Vac line power and converts that power to

acceptable low voltage signals used by other system components. Install

the electrical control box in the non-hazardous area.

Advanc

ed Display Module (E)

The Adv

anced Display Module (ADM) enables the user to setup, monitor,

and con

trol the system. Install the ADM in the non-hazardous area.

CAN cable (F) The CAN cable connects the Gateway communication module to theIS

remote mix control module.

332458B

11