Grounding

Grounding

See illustration on next page.

This equipment must be grounded to reduce the

risk of static sparking and electric shock. Electric

or static sparking can cause fumes to ignite or

explode. Improper grounding can cause electric

shock. Grounding provides an escape wire for the

electric current.

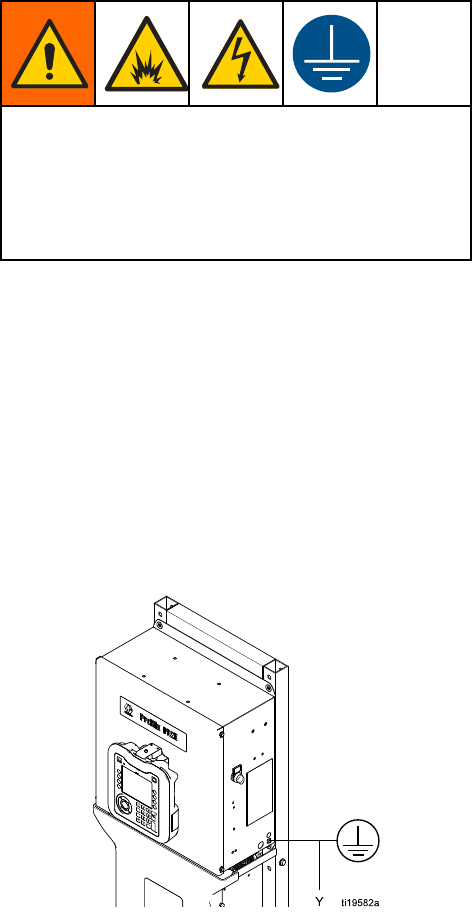

Electrical Control Box

The electrical control box has two ground points.

Both connections must be made.

• Connectthegroundwire(Y)tothegroundscrew

on the electrical control box. Connect the clamp

end to a true earth ground.

• The power supply must be grounded according to

local codes. Connect the power supply ground

wire to the Ground terminal in the electrical control

box. See Electrical Connections, page 25.

Figure 15 Ground Screw and Power Switch

Fluid Supply Container

Follow local code.

Color Change

Module

Connect a ground wire from the color change module

to a true earth ground.

Intrinsica

lly safe color change modules located in the

hazardous

area must be connected to a true earth

ground in t

he hazardous area.

Feed Pumps or Pressure Pots

Connect a ground wire and clamp from a true earth

ground to the pumps or pots. See pump or pressure

pot manual.

Air and F

luid Hoses

Use grounded hoses only.

Spray Gun

Follow

the grounding instructions in your gun manual.

• Non-Electrostatic: Ground the spray gun through

connection to a Graco-approved grounded fluid

supply hose.

• Electrostatic: Ground the spray gun through

connection to a Graco-approved grounded air

supply hose. Connect the air hose ground wire to

a true earth ground.

26 332458B