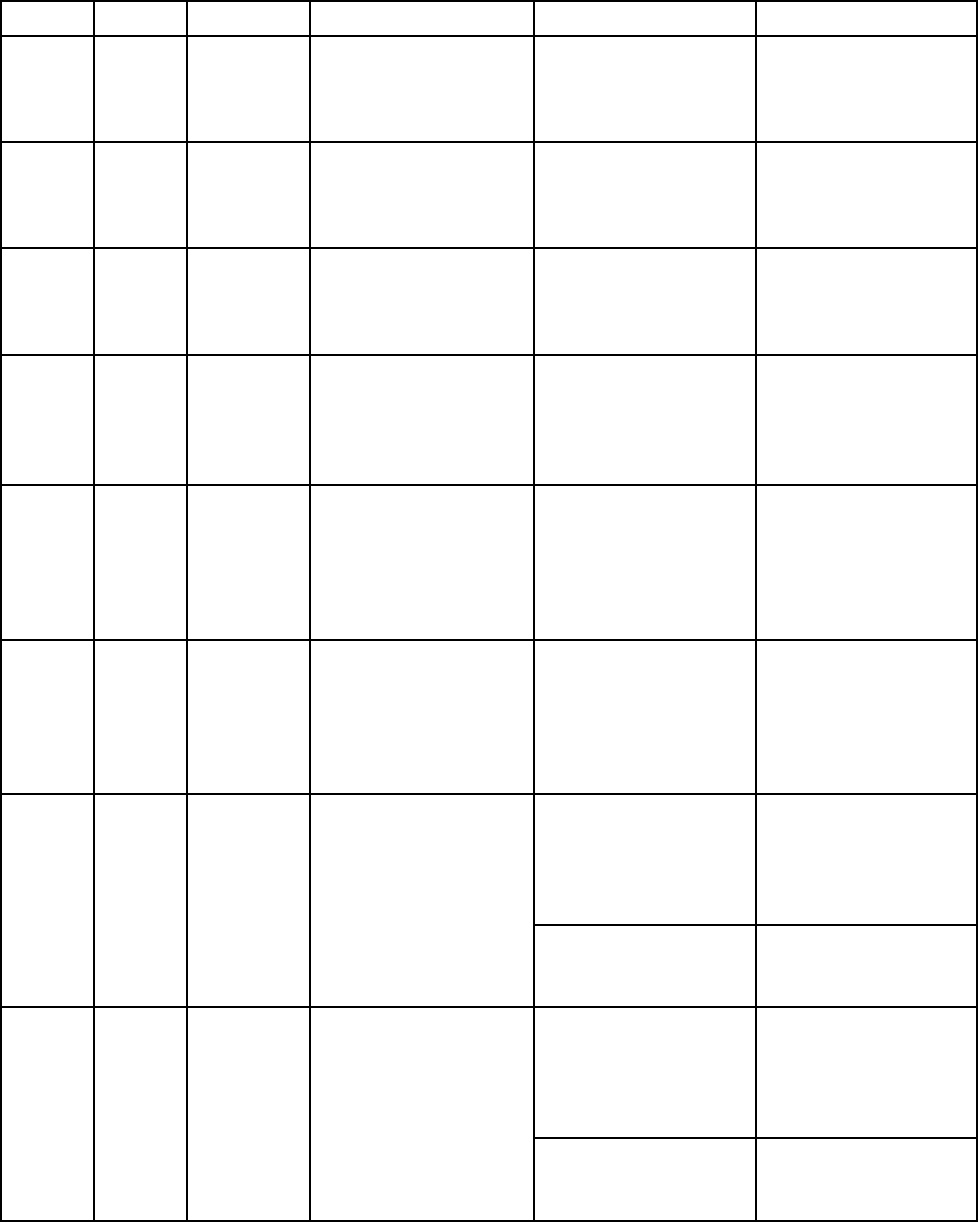

Troubleshootin

g

Code

Type Description Problem

Cause Solution

P3F#

Devia-

tion

Pressure

High Inlet

Pump #

The inlet pressure

on pump # is greater

than the user-entered

deviation limit.

Decrease inlet

pressure.

P4D#

Alarm Pressure

High Outlet

Pump #

The outlet pr

essure on

pump # is grea

ter than

the user ente

red alarm

limit.

Relieve syst

em

pressure.

P4F#

Alarm Pressure

High Inlet

Pump #

The inlet pressure on

pump # is greater than

the user-entered alarm

limit.

Decrease inlet

pressure.

P6D#

Alarm Press.

Sens.

Removed

Outlet #

No outlet pressure

transducer is detected

when the system is

expecting one

Disconnected

transducer.

Verify tra

nsducer

is connect

ed

properly

. Replace if

reconnec

ting does not

eliminat

e the alarm.

P9D#

Alarm Press.

Sens.

Failed

Outlet #

Outlet pressure

transducer has failed.

Outlet pressure

transducer has failed

orthepressureis

above the readable

range.

Relieve system

pressure. Verify

connections, or

replace if reconnecting

does not eliminate the

alarm.

P9F#

Alarm Press.

Sens.

Failed Inlet

#

Inlet pressure

transducer has failed.

Inlet pressure

transducer has failed

orthepressureis

above the readable

range.

Relieve system

pressure. Verify

connections, or

replace if reconnecting

does not eliminate the

alarm.

There

isaleakonthe

Bside

.

Check the system

for internal and

external leaks on

all catalyst manifolds

and plumbing.

QADX

Alarm

Differential

Pressure A

Over B

Low differential

pressure. This alarm is

active only during Mix

mode.

The B side pump is

cavitating.

Che

ck paint supply on

the

B side, increase

pai

nt supply pressure.

There is a leak on the

Aside.

Check the system

for internal and

external leaks on

all color manifolds and

plumbing.

QBDX

Alarm

Differential

Pressure B

Over A

High differential

pressure. This alarm is

active only during Mix

mode.

T

he A side pump is

c

avitating.

Check paint supply on

the A side, increase

paint supply pressure.

18 332709B