Installation

333309E 15

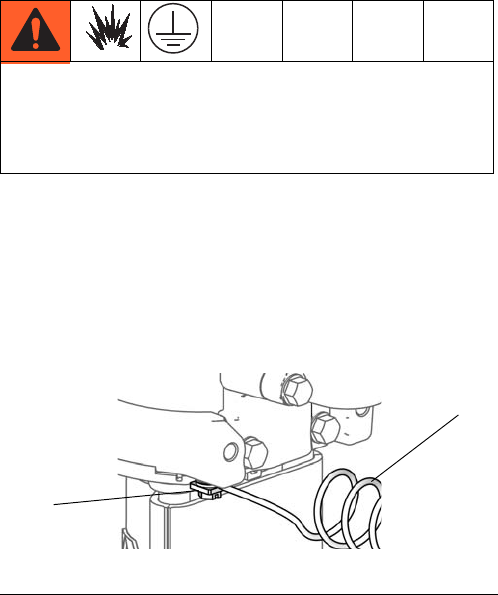

Grounding

The following components must be grounded.

1. Pump

See F

IG. 4. Verify that the ground screw (GS) is

attached and tightened securely to the air motor.

Connect the other end of the ground wire (S) to a

true earth ground.

2. Pump fluid hoses

Use only electrically conductive fluid hoses. Check

electrical resistance of hoses. If total resistance to

ground exceeds 25 megohms, replace hose

immediately.

3. Air compressor

Follow manufacturer's recommendations.

4. Spray gun

Ground through connection to a properly grounded

fluid hose and pump.

5. Fluid supply container

Follow your local code.

6. Object being sprayed

Follow your local code.

7. Solvent pails used when flushing

Use only metal pails, which are conductive, placed

on a grounded surface. Do not place the pail on a

non-conductive surface, such as paper or

cardboard, which interrupts the grounding

continuity. All solvent pails used when flushing must

be grounded according to local code.

NOTE: To maintain grounding continuity when flushing

or relieving pressure, hold a metal part of the spray gun

firmly to the side of a grounded metal pail, then trigger

the gun.

The equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes to

ignite or explode. Grounding wire provides an escape

path for static electric current.

F

IG. 4. Ground screw and wire

S

GS

ti12914a