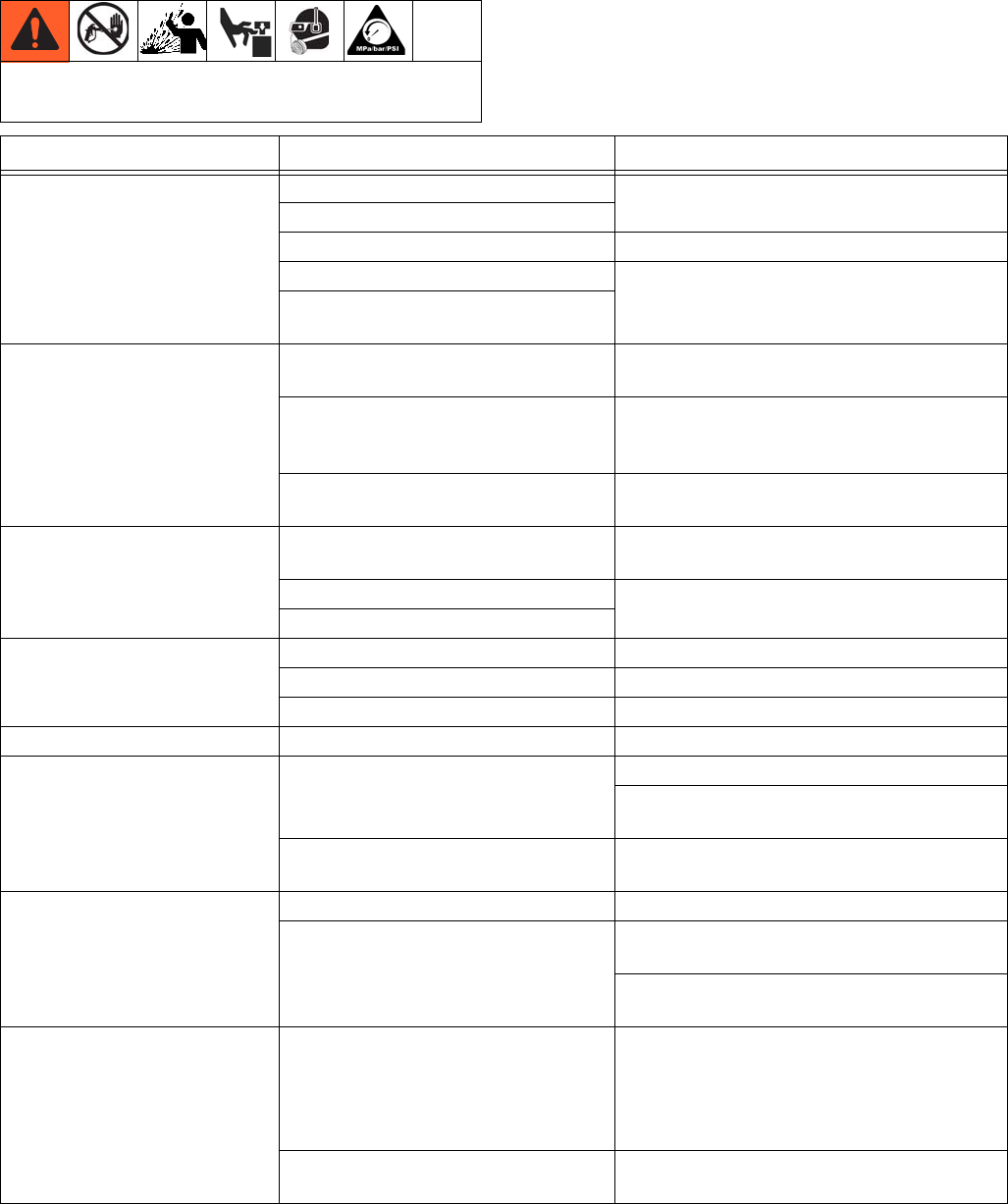

Troubleshooting

333309E 31

Troubleshooting

NOTE: Check all possible problems and causes before

disassembling the pump.

To avoid serious injury, always Relieve the pressure

before checking or servicing the equipment.

Problem Cause Solution

Pump does not cycle Air supply pressure not “on” Verify air supply is on and pressure set high

enough to cycle pump

Air supply pressure set too low

Mix manifold turned to off position Place manifold in mix position

Gun tip is plugged Make sure that the Fluid lines are clear and

open for mixed paint flow

Mix manifold or mixed material hose

plugged

Pump does not load material Suction hose is plugged Make sure suction hose and tube are clear

and free of caps or plugged strainers.

Pump is vapor locked Open a gun or drain valve to allow for air to

escape the system while filling with paint or

solvent.

Paint viscosity is too high to siphon Make sure paint is thin enough to siphon to

the pump

Pump cycles erratically Air supply is too restricted The air supply hose should be a minimum of

3/8” id and a max of 50 ft in length.

Pump packing’s are dry Check TSL level in wet cups. Verify pump is

loading fully on up stroke

Pump cavitation

Fluid pressures are low Air supply is too restrictive Use a larger air hose

Pump friction is high Check TSL level in wet cup

Fluid filters plugging Clean fluid filters

Paint not mixed Static mixer is not clean Replace static mixer

Paint not at correct ratio Pump cavitation Suction tube and hose restricted

Suction hose and tube fittings are loose

allowing suction of air into pump

Ball check in pump is not checking Pump is contaminated with dried paint or

foreign materials

System speeds up or runs

erratically

Pump cavitation Suction tube and hose restricted

Pump checks are not checking con-

sistently

Suction hose and tube fittings are loose

allowing suction of air into pump

Pump is contaminated with dried paint or

foreign materials

A and B fluid pressures not

equal

Very different viscosities Can be OK. Should not exceed 10% differ-

ential with unit mounted mix manifold.

Remote mounted mix manifold A and B

pressures may have a greater differential,

but greater than 20% can cause ratio errors.

Mix manifold check valves and ports

restricted by cured paint

Clean and repair mix manifold