Operation

28 333309E

8. Reconnect the suction tube assembly.

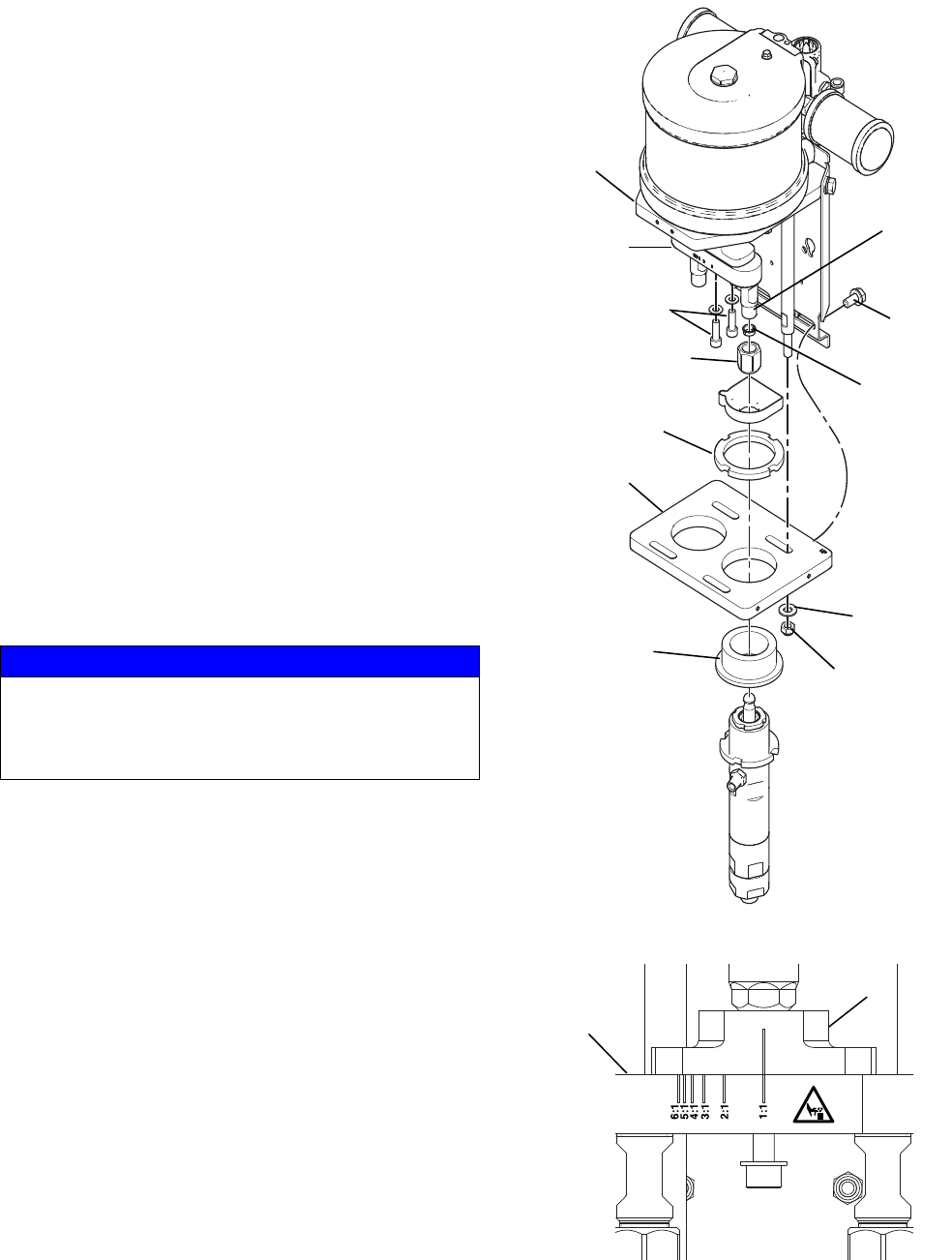

Adjust Pump Assembly for Balanced Yoke

Forces

At each ratio setup the pump assembly must be

adjusted to balance the yoke forces. To adjust the pump

assembly:

1. Loosen mounting plate screw (44, 2 locations)

2. Loosen yoke bolts (33, 2 locations).

3. Loosen Tie rod nuts (14, 4 locations)

4. Slide the yoke (32) until the desired ratio marks on

the yoke (32) align with the center line mark on the

connector (31). See Detail A.

5. Remove yoke assembly screws (33, 2 locations),

clean threads and apply medium strength thread

adhesive. Re-install screws (33, 2 locations) and

tighten the yoke assembly screws (33, 2 locations),

while maintaining the mark alignment. Torque to 40

lb-ft (47-54 N•m).

6. Position the fluid assembly vertically under the yoke

and tighten the tie rod nuts (14), ensure washers

(15) are in place. Torque to 45 lb-ft (68-80 N•m).

7. Re-tighten mounting bracket screws (44) and torque

to 35 lb-ft. (47 N•m)

Cycle the pump slowly and observe up and down stroke

changeover verifying correct operation. If binding is

observed, re-align fluid pumps by repeating step 6.

NOTE: 1:1 and 6:1 ratios have yoke and pump posi-

tioned against yoke and plate slot ends. Adjusted full left

or right positions.

NOTICE

Verify that fluid pumps are aligned vertically under the

yoke position. If they are not aligned correctly, side

loading of motor and fluid pumps will occur, causing

premature wear to seals and bearings.

23

29

15

36

44

24

22

32

33

38

14

37

See Detail A

Detail A

32

31