Operation Basics

16 311321H

Valving Rod Adjustment

GX-7A and GX-7 400 Models Only

1. Push in rear stop to SERVICE position.

2. If attached, turn both manual valves fully

clockwise to close (see Manual Valves,

page 13).

3. Connect air line from gun to air source to

pressurize air cylinder forward to CLOSED

position.

4. Loosen forward stop locknut.

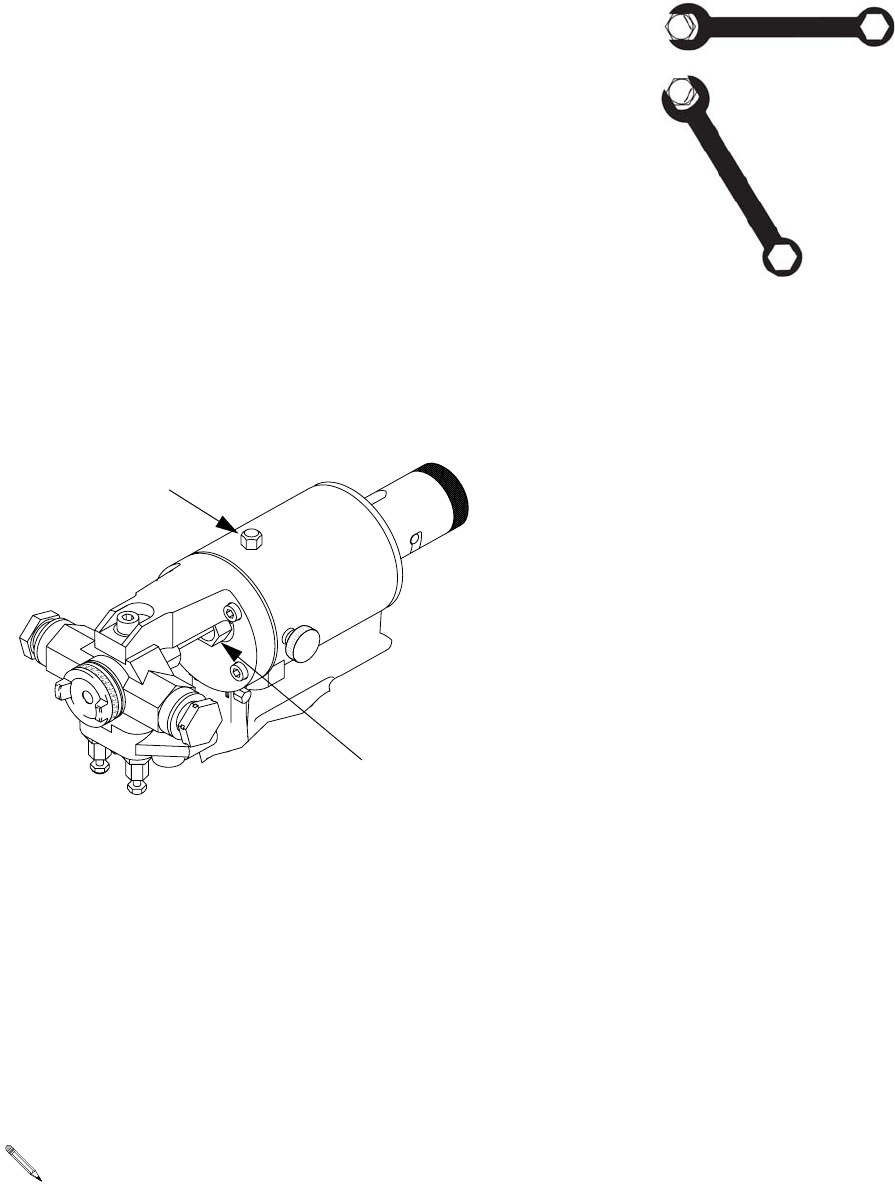

FIG. 17: Forward Stop

5. Completely loosen (full CCW) forward

stop. Then slowly tighten (CW) forward

stop until a snug resistance is felt. From

this point, reverse and loosen approxi-

mately 1/16 of a turn.

6. Tighten forward stop locknut. Do not over-

tighten. If locknut bottoms out before resis-

tance is felt, replace friction plug.

FIG. 18: One Wrench Flat

Valving Rod Adjustment

GX-7 DI Model Only

Valving rod requires adjustment in only the fol-

lowing instances:

• disassembly and service of air cylinder

• changing valving rod

• changing mixing module

1. Clean gun according to Clean Spray Gun

Procedure, page 20.

2. Connect air supply to gun.

3. Loosen rear seal retainer assembly one or

two turns.

4. Loosen locknut from valving rod three or

four turns.

5. Set safety stop to OPEN.

6. Use 5/16 in. nut driver through rear of gun

to thread valving rod forward to engage

PCD. When valving rod contacts PCD

tighten another 1/10 turn.

7. Carefully maintain position of valving rod

and tighten locknut against piston rod.

8. Retighten rear seal retainer assembly.

As a reference point, movement of one

wrench flat corresponds to 1/6 turn.

Forward

Stop

Forward Stop

Locknut