-20-

G0640X 17" Wood/Metal Bandsaw

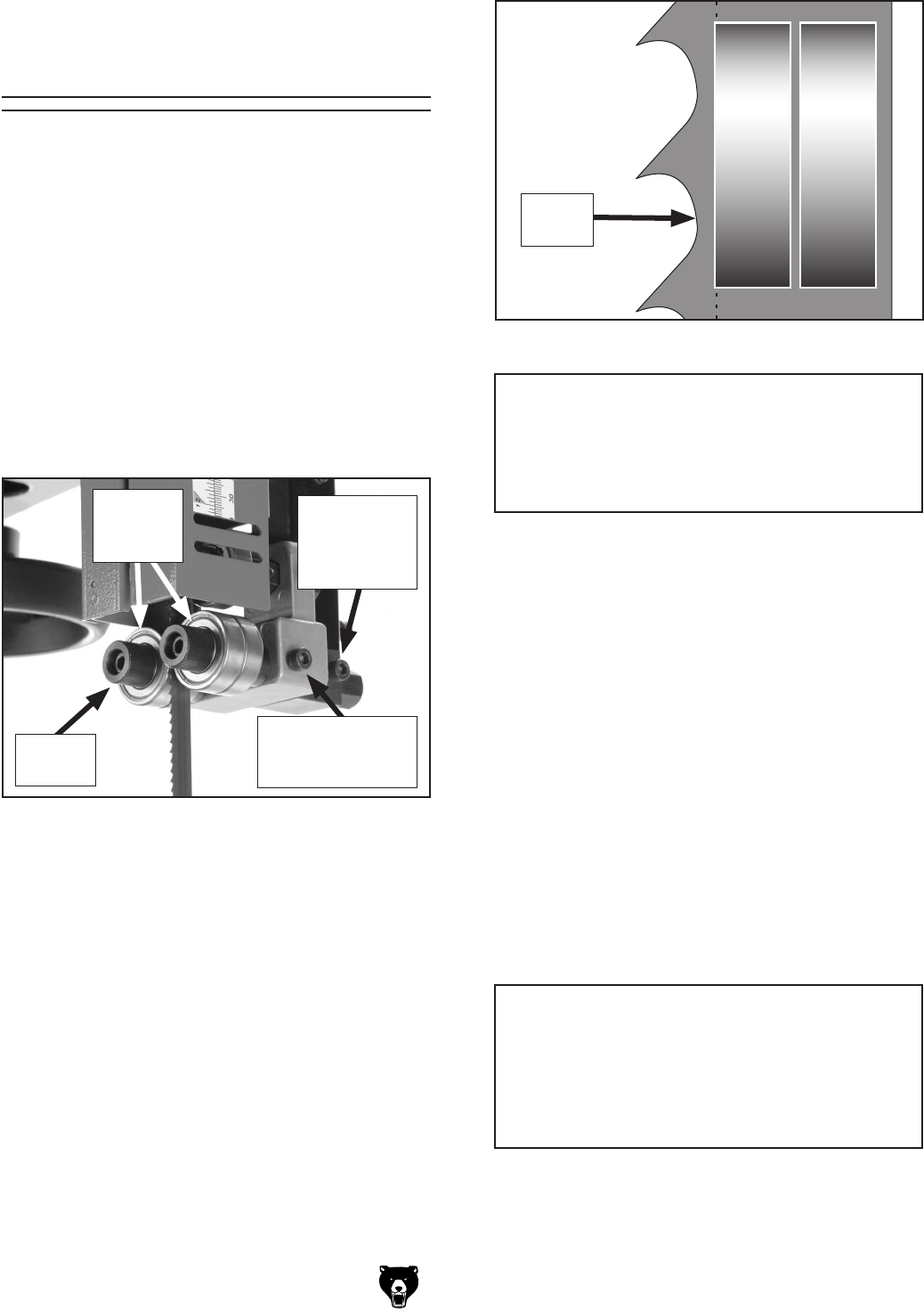

The blade guides provide side-to-side support to

help keep the blade straight while cutting. The

blade guides are designed to be adjusted in two

ways—forward/backward and side-to-side.

To adjust the upper and lower blade guides

:

1. Make sure the blade is tracking properly and

that it is correctly tensioned.

2. DISCONNECT BANDSAW FROM POWER!

3. Familiarize yourself with the upper blade

guide controls shown in

Figure 22.

Adjusting Blade

Guides

Figure 22. Blade guide controls.

Lateral

Adjustment

Rod Cap

Screw

Knurled

Knob

Blade

Guide

Bearings

Bearing Rotation

Adjustment Cap

Screw

4. Loosen the cap screw on the lateral adjust-

ment rod and adjust the blade guides until

the edges of the bearings are

1

/16" behind the

blade gullets, as illustrated in

Figure 23.

Note: The

1

/16" spacing is ideal, although with

larger blades it may not be possible. In such

cases, adjust the guide bearings as far for

-

ward as possible to the blade gullets, and still

maintain the proper support bearing spacing

adjustment.

Figure 23. Lateral adjustment of blade guides.

Blade

Gullet

NOTICE

Make sure that the blade teeth will not con-

tact the guide bearings when the blade is

against the rear support bearing during the

cut or the blade teeth will be ruined.

5. Tighten the cap screw on the lateral adjust-

ment rod.

6. Loosen the bearing rotation adjustment cap

screws.

7. Use the knurled knob to rotate the bearings

0.004" away from the blade.

Note: 0.004" is approximately the thickness

of a dollar bill.

8. Tighten the cap screw to lock the blade guide

bearings in position.

9. Repeat this procedure for the lower guides.

(All though the lower guides are set up a little

differently, the concept is the same.)

NOTICE

Whenever changing a blade or adjusting ten-

sion and tracking, the upper and lower blade

support bearings and guide bearings must

be properly adjusted before cutting opera

-

tions.