G0640X 17" Wood/Metal Bandsaw

-35-

Cutting Curves

When cutting curves, simultaneously feed and

turn the stock carefully so that the blade follows

the layout line without twisting. If a curve is so

abrupt that you must repeatedly back up and cut a

new kerf, use a narrower blade, a blade with more

TPI (teeth per inch), or make more relief cuts.

Always make short cuts first, then proceed to

the longer cuts. Relief cuts will also reduce the

chance that the blade will be pinched or twisted.

Relief cuts

are cuts made through the waste

portion of the workpiece and are stopped at the

layout line. As you cut along the layout line, waste

wood is released from the workpiece, alleviating

any pressure on the back of the blade.

Stacked Cuts

One of the benefits of a bandsaw is its ability to

cut multiple copies of a particular shape by stack

-

ing a number of workpieces together. Before mak

-

ing stacked cuts, ensure that both the table and

the blade are properly adjusted to 90°. Otherwise,

any error will be compounded.

To complete a stacked cut:

1. Align your pieces from top to bottom to

ensure that each piece has adequate scrap

to provide a clean, unhampered cut.

2. Secure all the pieces together in a manner

that will not interfere with the cutting. Hot

glue on the edges works well, as do brad

nails through the waste portion. (Be careful

not to cut into the brads or you may break the

blade!)

3. On the face of the top piece, lay out the

shape you intend to cut.

4. Make relief cuts perpendicular to the out-

line of your intended shape in areas where

changes in blade direction could strain the

woodgrain or cause the blade to bind.

5. Cut the stack of pieces as though you were

cutting a single piece. Follow your layout line

with the blade kerf on the waste side of your

line, as shown in

Figure 46.

Figure 46. Typical stacked cut.

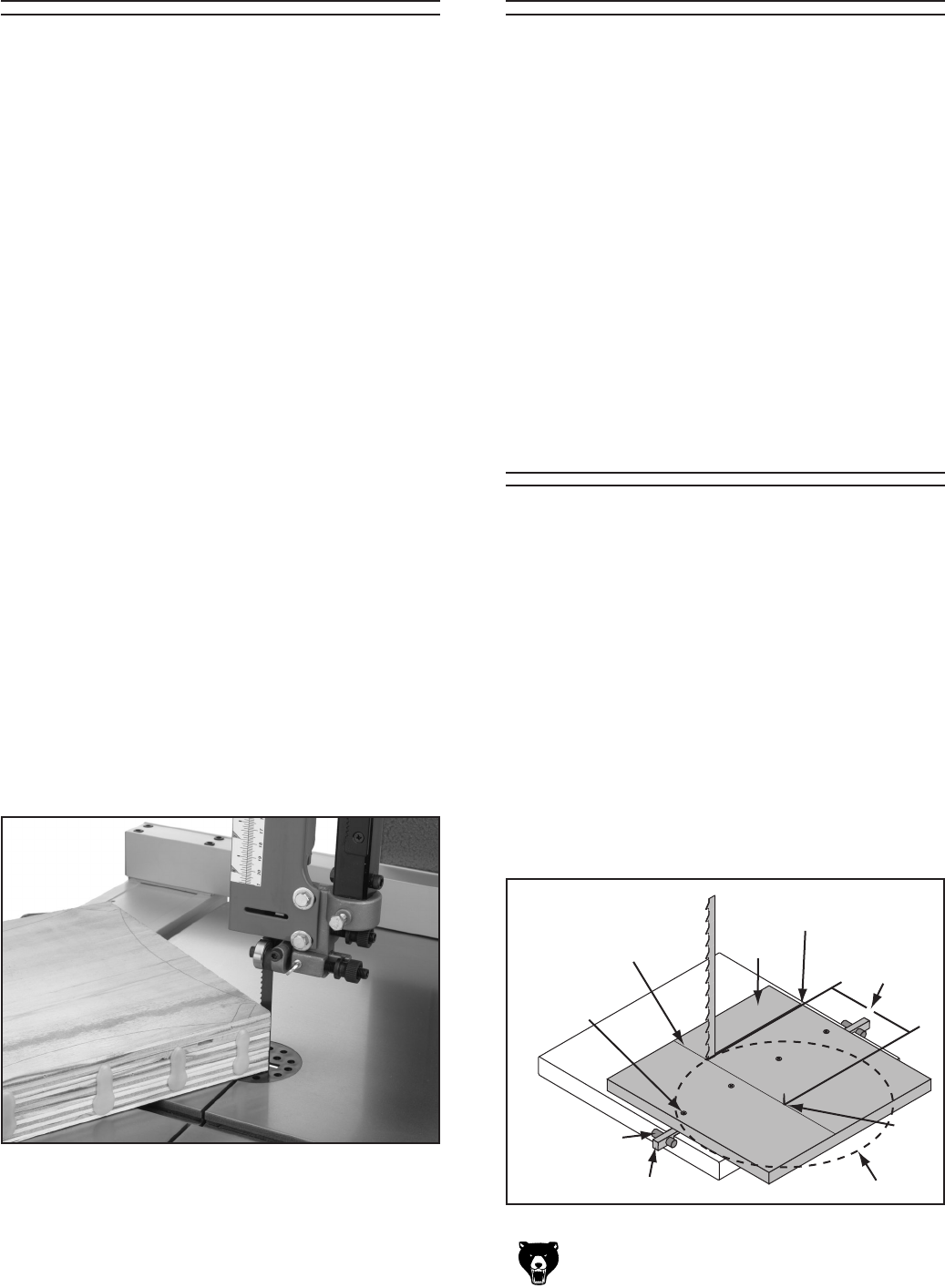

Cutting Circles

Bandsaws can cut circles with the use of a shop-

built or aftermarket jig. Typically, these jigs work

on the same principal as a drafting compass.

Figure 47 below shows a generic shop built jig

that can be easily made of wood, dowels, and

wood screws. To set it up, advance the jig forward

until the stop dowel hits the table, then pencil a

square "radius" line across the jig. A nail can be

placed anywhere on the radius line, depending on

the size of the desired circle. Draw an X across

the bottom of the workpiece and drill a small pivot

hole in the center of the X to place on the nail.

Place the workpiece on the nail, advance the jig to

the stop dowel, place rear dowel, then cut circle.

Figure 47. Example shop-built circle cutting jig.