-50-

G0640X 17" Wood/Metal Bandsaw

NOTICE

Lead adjustments will change when new

blades are mounted on the saw.

NOTICE

If the table is shifted, the fence will need

to be re-aligned, and the blade guides and

blade support will need to be re

-adjusted.

3. Clamp the board to the bandsaw table with-

out moving it. Now slide the fence over to

the board so it barely touches one end of the

board.

4. Loosen the four cap screws on top of the

fence.

5. Skew the fence so it is parallel to the edge of

the scrap piece. You may need to re-adjust

the fence locking mechanisms to gain maxi

-

mum adjustment.

6. While maintaining the skew, tighten the cap

screws.

To shift the table:

1. On a scrap piece of wood, mark a line that is

perpendicular to the front edge.

2. Cut halfway through the board on the line by

pushing it into the blade.

3. Turn the bandsaw OFF and wait for the blade

to stop.

4. Loosen the the table mounting bolts, shift the

table to compensate for the blade lead, then

retighten the bolts.

5. Repeat Steps 1–4 until the blade cuts

straight.

Adjusting Tension

Lever

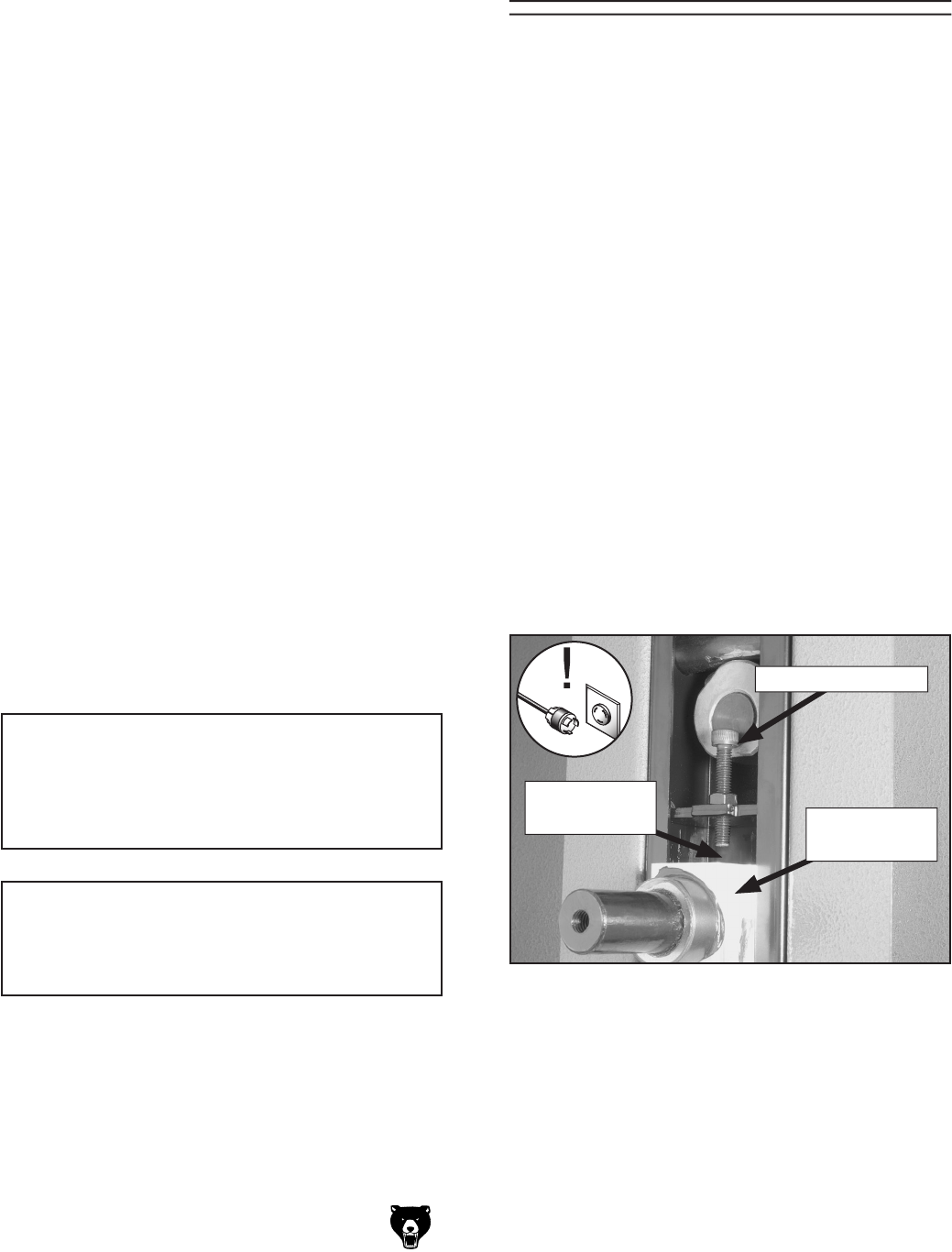

The tension lever has an adjustment screw that

allows you to adjust how much tension is released

when the lever is used.

Tools Needed: QTY

Hex Wrench 6mm .............................................. 1

Hex Wrench 5mm ..............................................

1

To adjust the tension lever:

1. DISCONNECT BANDSAW FROM POWER!

2. Loosen the tension lever and remove the

blade.

3. Remove the upper wheel by taking out the

cap screw at the center of the wheel.

4. Move the tension lever to the tightened posi-

tion.

5. Turn the adjustment screw shown in Figure

68 until the gap between the screw and the

wheel shaft hinge is

1

⁄16"–

3

⁄16".

6. Reassemble the removed components and

tension and track the blade as normal.

Adjustment Screw

Wheel Shaft

Hinge

Figure 68. Tension lever adjustment

components.

Adjustment

Gap

1

⁄8"-

3

⁄16"