-42-

G0640X 17" Wood/Metal Bandsaw

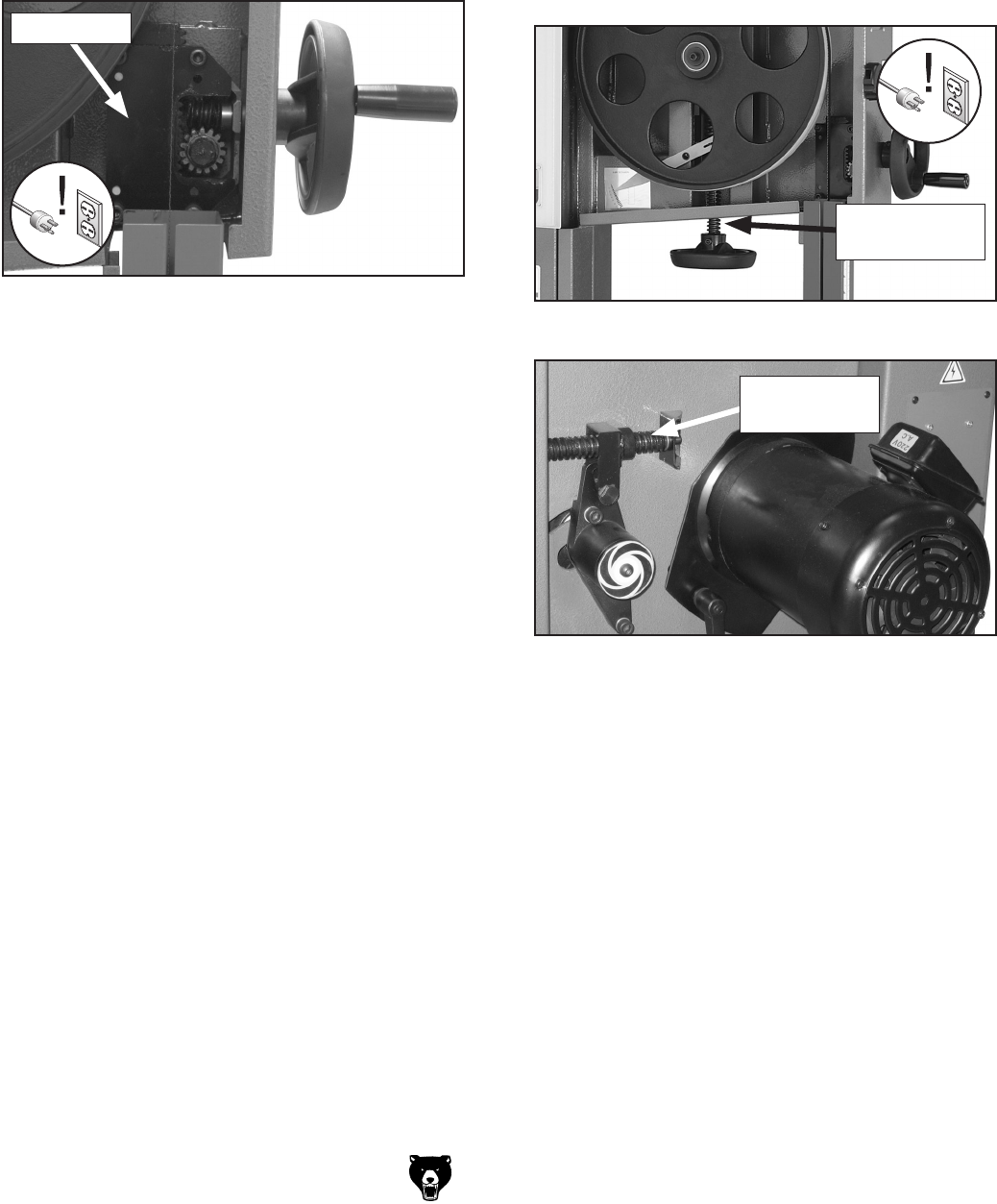

Guide Post Gears

1. DISCONNECT BANDSAW FROM POWER!

2. Lower the guide post down so the upper

guide bearings almost touch the table, then

open the upper wheel cover to access the

gears, shown in

Figure 56.

3. Use a 6mm hex wrench to remove the four

cap screws that hold the cover plate in place.

(The gears can be greased without removing

the cover plate, but removing the cover plate

makes cleaning easier.)

4. Wipe as much of the old grease off the gears

as possible, and also wipe off the rack (the

long plate with teeth that contact the pinion

gear). The old grease will be contaminated

with wood or metal dust, so you want to

remove as much of it as possible.

5. Use mineral spirits or the degreaser shown in

Figure 4 on Page 12 to clean any remaining

grease from the gears and rack. Make sure to

thoroughly wipe off the degreaser or mineral

spirits after use so they won't contaminate

the new grease.

6. Use a small, clean brush to apply automo-

tive-grade multi-purpose grease to the pinion

gear. After applying, rotate the handle two or

three times to distribute the grease.

7. Coat the inside cover plate with a light layer

of grease and replace it.

8. Close the upper wheel cover, and re-adjust

the guide post height as necessary.

Blade and Belt Tension Leadscrews

1. DISCONNECT BANDSAW FROM POWER!

2. Wipe as much of the old grease off the lead-

screws (

Figures 57 & 58) as possible. The

old grease will be contaminated with wood or

metal dust, so you want to remove as much

of it as possible.

3. Use mineral spirits or the degreaser shown in

Figure 4 on Page 12 to clean any remaining

grease from the leadscrews. Make sure to

thoroughly wipe off the degreaser or mineral

spirits after use so they will not contaminate

the new grease.

4. Use a small, clean brush to apply automo-

tive-grade multi-purpose grease to the lead

-

screws. After applying, rotate the handles

through their full range of motion to distribute

the grease.

5. Close the upper wheel cover, and re-adjust

the blade and belt tension as necessary.

Figure 58. Belt tension crank leadscrew.

Belt Tension

Lead Screw

Figure 56. Guide post gears.

Cover Plate

Figure 57. Blade tension leadscrew.

Blade Tension

Lead Screw