-38-

G0555X 14" Extreme Series Bandsaw

To ensure optimum power transfer from the motor

to the blade, the belt must be in good condition

and operate under proper tension. The belt should

be replaced if has for cracks, fraying, or excessive

wear. Belt tension should be checked at least

every 3 months—more often if the bandsaw is

used daily.

To check the belt:

1. DISCONNECT BANDSAW FROM POWER!

2. Open the lower wheel cover.

3. Check the belt tension. When tensioned

correctly, the middle of the belt will deflect

approximately

1

⁄4" when pushed with moder-

ate pressure (see

Figure 41).

To tension the belt:

1. DISCONNECT BANDSAW FROM POWER!

2. Open the lower wheel cover.

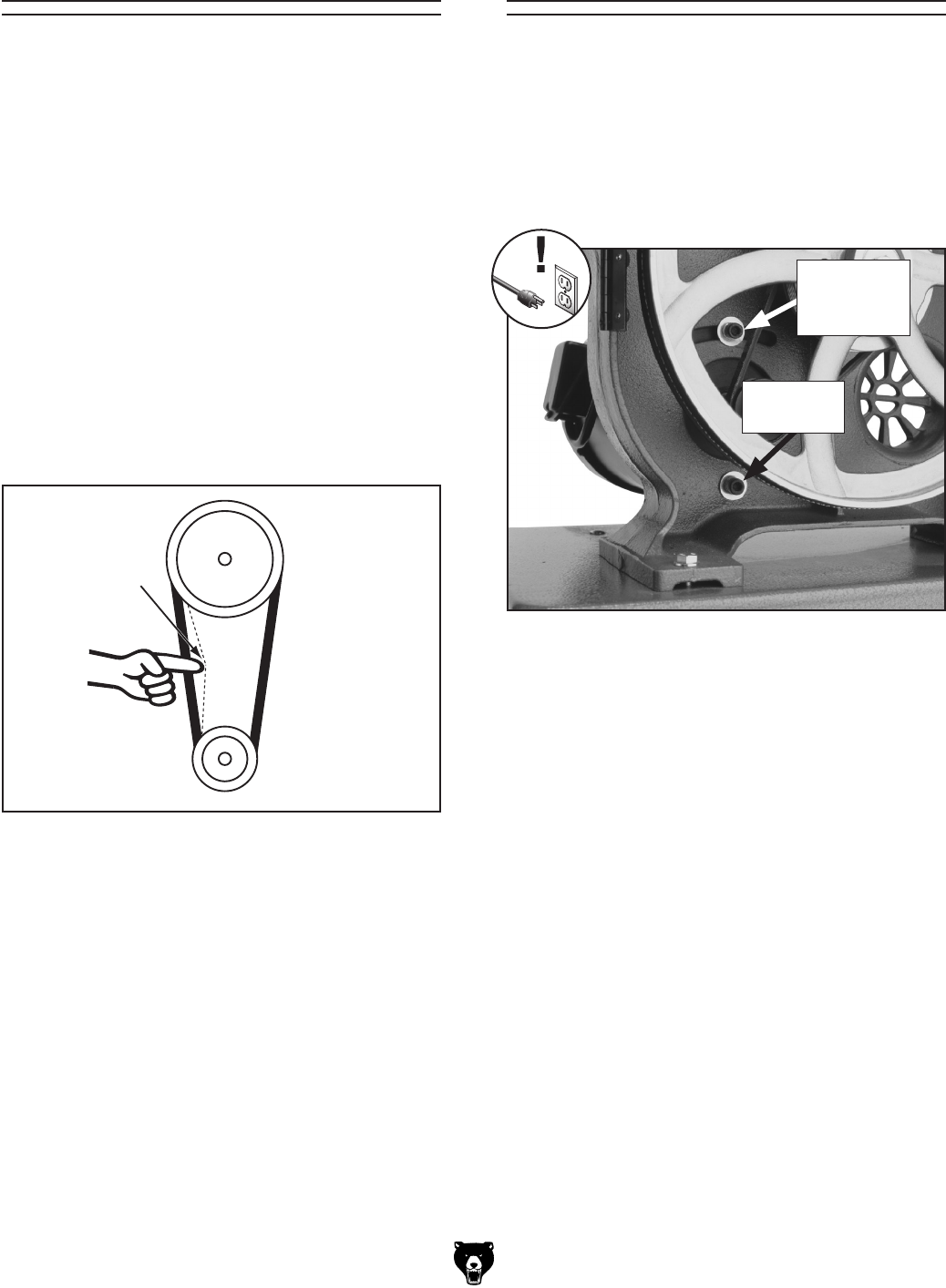

3. Loosen the motor mount bolts shown in

Figure 42.

Figure 42. Motor mount bolts.

Motor

Hinge Bolt

Motor

Adjustment

Bolt

4. Move the body of the motor so the motor

adjustment bolt slides to the left-hand side of

the adjustment slot.

5. Hold the motor in position with one hand and

tighten the motor adjustment bolt with the

other hand.

6. Push the center of the belt. If deflection is

approximately

1

⁄4" with moderate pressure

from your thumb or finger, then the tension

is correct. If the deflection is more than

1

⁄4",

repeat Steps 3–6.

7. When the belt tension is correct, tighten the

motor hinge bolt and close the lower wheel

cover.

Checking Belt Tensioning Belt

4. Note the condition of the belt. If the belt

is cracked, frayed, or glazed; it should be

replaced as soon as convenient.

Figure 41. Belt deflection.