"()"

BdYZa<%+%'B[\#H^cXZ.$%-

JhZi]ZhZhiZehidaZVgc]dlidhZijendjgaVi]Z

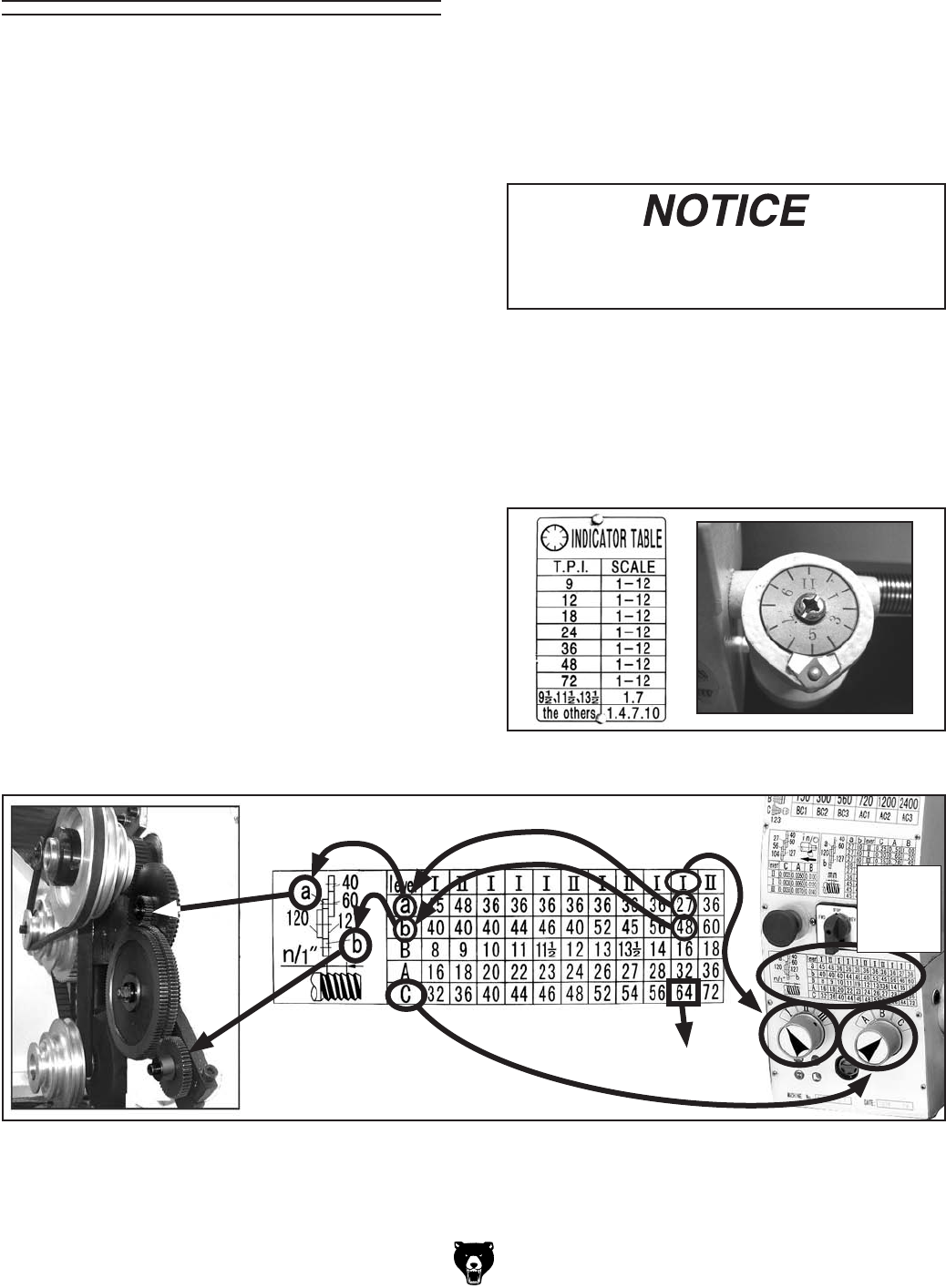

[dg ^cX] i]gZVY^c\# I]Z ZmVbeaZ ^c Figure 36

h]dlhaVi]ZhZije [dgXjii^c\ +)IE>IZZi]EZg$

>cX]i]gZVY#

To setup for inch threading:

1. 9>H8DCC:8II=:A6I=:;GDB

EDL:G

2. Ijgci]Z[ZZYY^Vahidi]ZcjbZgVaVcYaZiiZg

^cY^XViZYWni]ZX]Vgi^c Figure 36#

Note: You may have to rock the chuck by

hand slightly to get the gearbox gears to

engage one another.

3. Jh^c\ i]Z X]Vgi ^c Figure 36! \Vi]Zg i]Z

gZfj^gZYX]Vc\Z\ZVgh#

4. DeZc i]Z h^YZ XdkZg VcY jhZ V +bb ]Zm

lgZcX] id addhZc i]Z aVh] VY_jhiZg Figure

34VcYhl^c\i]ZX]Vc\Z\ZVgVhhZbWandji

d[i]ZlVn#

5. GZbdkZ i]Z he^cYaZ:"Xa^eh VcY XVe hXgZl!

ajWg^XViZ!VcYhlVedjii]ZX]Vc\Z\ZVgh^c

i]ZdgYZgh]dlcdci]ZX]Vgi^cFigure 34.

Note:All change gears are stamped with the

number of teeth they have.

Inch Threads

6. BdkZ i]Z aVh] VY_jhiZg hd i]Z \ZVg WVX`"

aVh]^hWZilZZc%#%%(id%#%%-!i^\]iZci]Z

aVh] VY_jhiZgXVe hXgZl!VcY XadhZi]Z h^YZ

XdkZg#

7. Jh^c\V*bb]ZmlgZcX]!bV`ZhjgZi]ZXVg"

g^V\ZadX`^haddhZFigure 33#

8. I]ZaVi]Z^hcdlhZije[dgi]gZVY^c\#

Figure 35.I]gZVYY^VaX]VgiVcYi]gZVYY^Va#

Figure 36.>cX]i]gZVY^c\hZije#

= 64 TPI

b

>cX]

I]gZVY

8]Vgi

a

Note: For faster threading and manual carriage

return, based on which TPI being cut, refer to the

Indicator TableinFigure 35 to know if you can

use the thread dial scale to show when to re-enter

the thread manually after disengaging the half nut

lever.

During threading keep your hand on the

half-nut lever ready to disengage the half

nut to avoid potential carriage/chuck crash.