G0633/G0634 Jointer/Planer Combo Machine

-51-

— If the table is not parallel to the cutterhead

side-to-side (Figure 75), loosen the two

lock nuts on the right or left side of the cyl

-

inder liner. Adjust the set screws to raise

or lower the table so it is parallel to the

cutterhead.

— If the table is not parallel to the cutterhead

front-to-back (

Figure 76), loosen the two

lock nuts at the front or back of the cylinder

liner. Adjust the set screws to raise or lower

the front or back of the table so it is parallel

to the cutterhead.

4. Tighten the four cap screws on the cylinder

liner.

Spring Tension

Tools Needed: Qty

Hex Wrench

6mm .............................................. 1

Roller spring tension must be adjusted so that

feed roller pressure is uniform. Roller spring ten

-

sion will vary, depending on the type of wood you

plane. This is usually determined from trial-and-

error.

Generally speaking, less spring tension is more

forgiving on workpieces. Therefore, if you primar

-

ily plane milled lumber with relatively consistent

surfaces, you can get away with having less

spring tension. Likewise, if you primarily plane

rough lumber with inconsistent surface heights,

more spring tension is a must to keep the

workpiece feeding through the planer without

stopping.

If workpieces regularly stop feeding during opera

-

tion, it may be a sign of weak spring tension.

To adjust feed roller spring tension:

1. Locate the four adjustment screws located

on the top of the planer, as shown in

Figure

78.

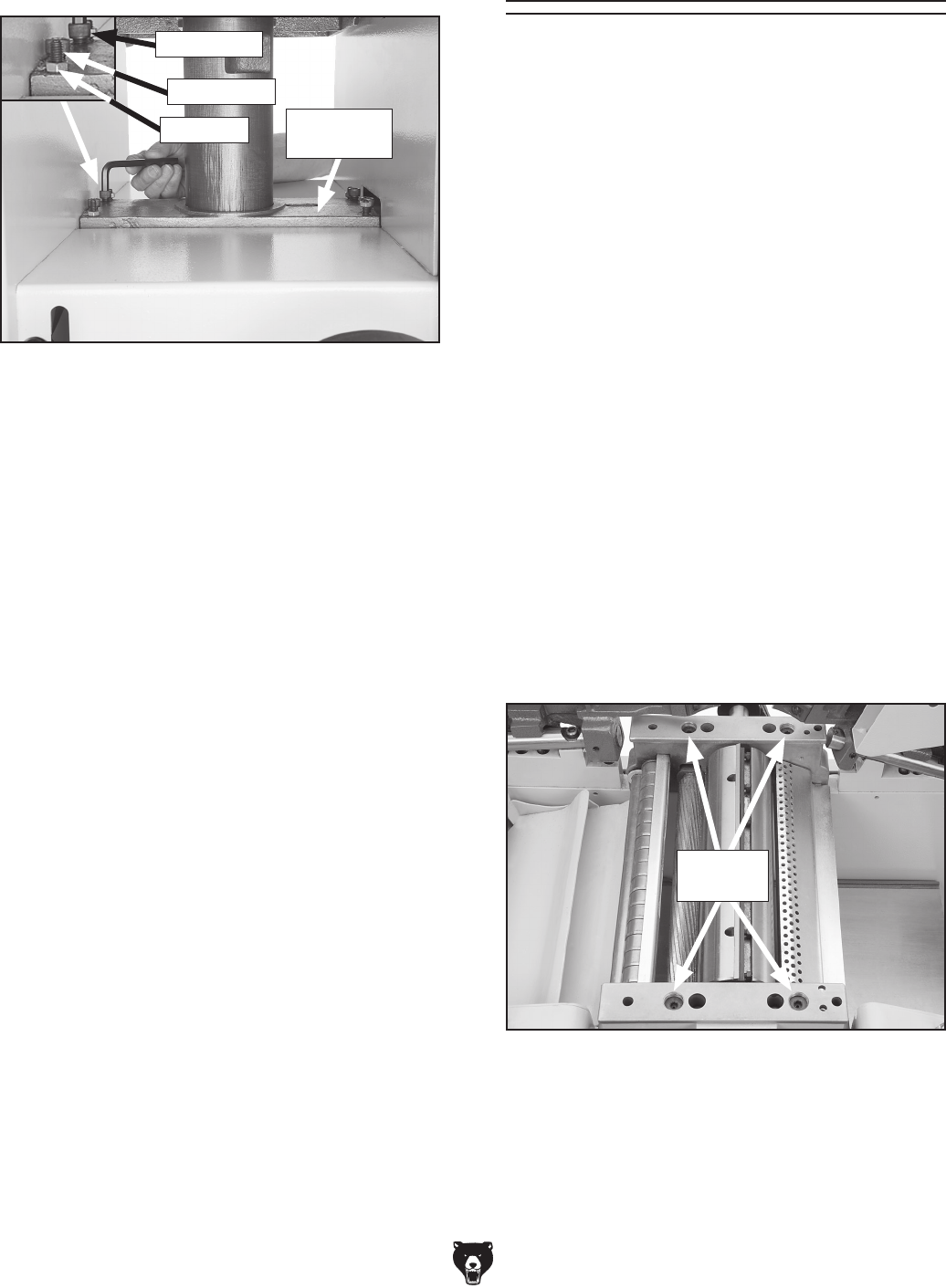

3. Loosen the four cap screws on the cylinder

liner, as shown in

Figure 77.

Figure 77. Adjusting table parallelism.

Cylinder

Liner

Figure 78. Spring tension screws.

Tension

Screws

Lock Nut

Set Screw

Cap Screw