-12-

G0668 20" Vertical Metal-Cutting Bandsaw

Floor Load

Refer to the Machine Data Sheet on Page 3 for

the weight and footprint specifications of your

machine. Some floors may require additional

reinforcement to support both the machine and

operator

.

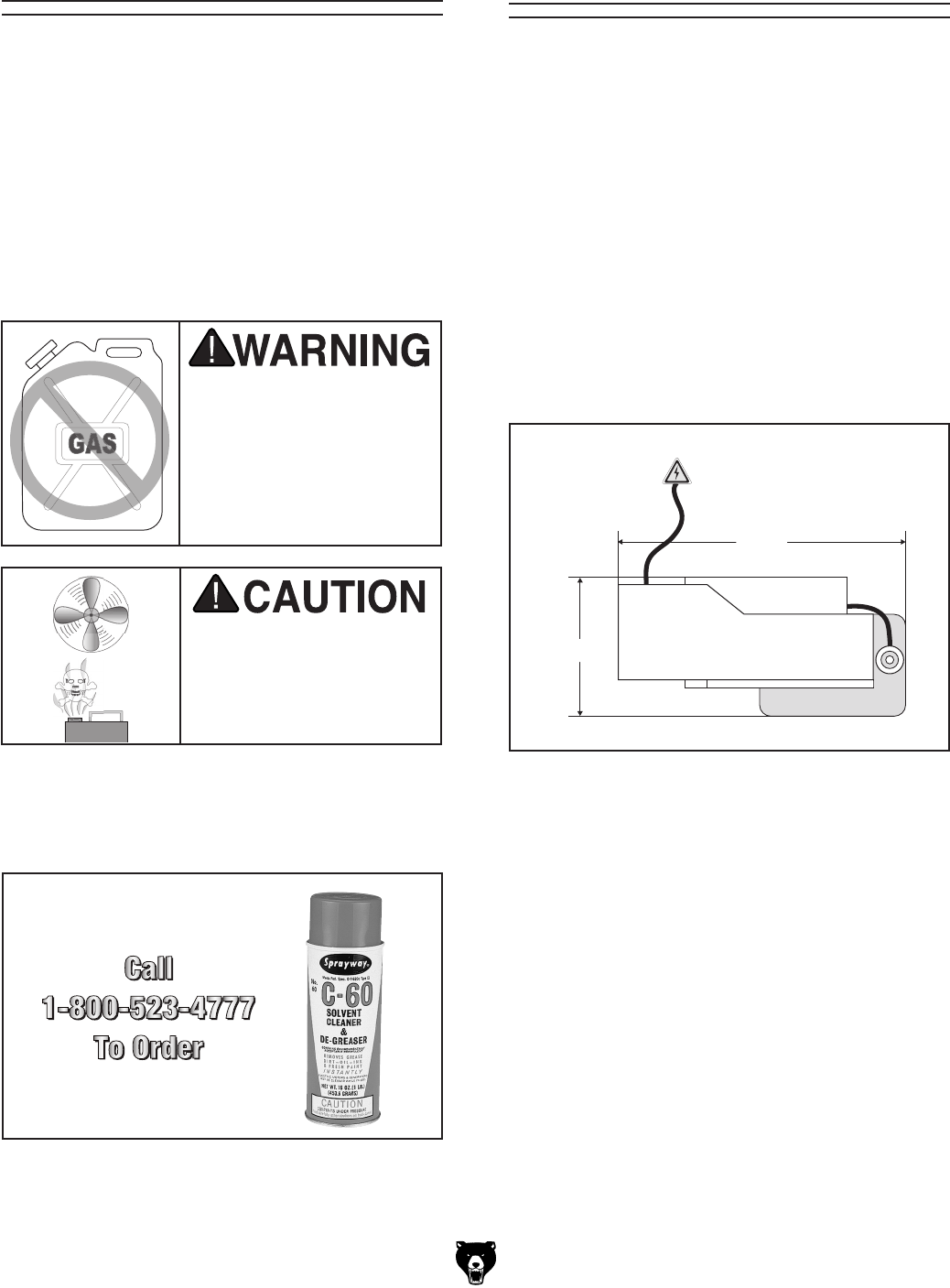

Placement Location

Consider existing and anticipated needs, size of

material to be processed through each machine,

and space for auxiliary stands, work tables or

other machinery when establishing a location for

your new machine. See Figure

5 for the minimum

working clearances.

Site Considerations

Figure 5. Minimum working clearances (top

view).

The unpainted surfaces are coated with a waxy

oil to prevent corrosion during shipment. Remove

this protective coating with a solvent cleaner

or degreaser shown in Figure

4. For thorough

cleaning, some parts must be removed. For opti

-

mum performance from your machine, clean

all moving parts or sliding contact surfaces.

Avoid chlorine-based solvents, such as acetone

or brake parts cleaner that may damage painted

surfaces. Always follow the manufacturer’s instruc

-

tions when using any type of cleaning product.

Clean Up

Gasoline and petroleum

products have low flash

points and can explode

or cause fire if used to

clean machinery. DO

NOT use these products

to clean the machinery.

Many cleaning solvents

are toxic if inhaled.

Minimize your risk by only

using these products in a

well ventilated area.

G2544—Solvent Cleaner & Degreaser

A great product for removing the waxy shipping

grease from your machine during clean up.

Figure 4. Cleaner/degreaser available from

Grizzly.

degreaser