-36-

G0668 20" Vertical Metal-Cutting Bandsaw

Tensioning V-Belts

tensioning v-belts

Tools Needed: Qty

Wrench 12mm ...................................................

1

To ensure optimum power transfer from the motor

to the blade without slipping, the V-belts must be

in good condition and operate under proper ten

-

sion. Check V-belt tension at least monthly—more

often if the bandsaw is used daily. V-belts stretch

with use and must be periodically re-tensioned.

To check/tension/replace the V-belts:

1. DISCONNECT BANDSAW FROM POWER!

2. Remove the rear motor access panel.

3. Make sure the motor and lower wheel pulleys

are correctly aligned.

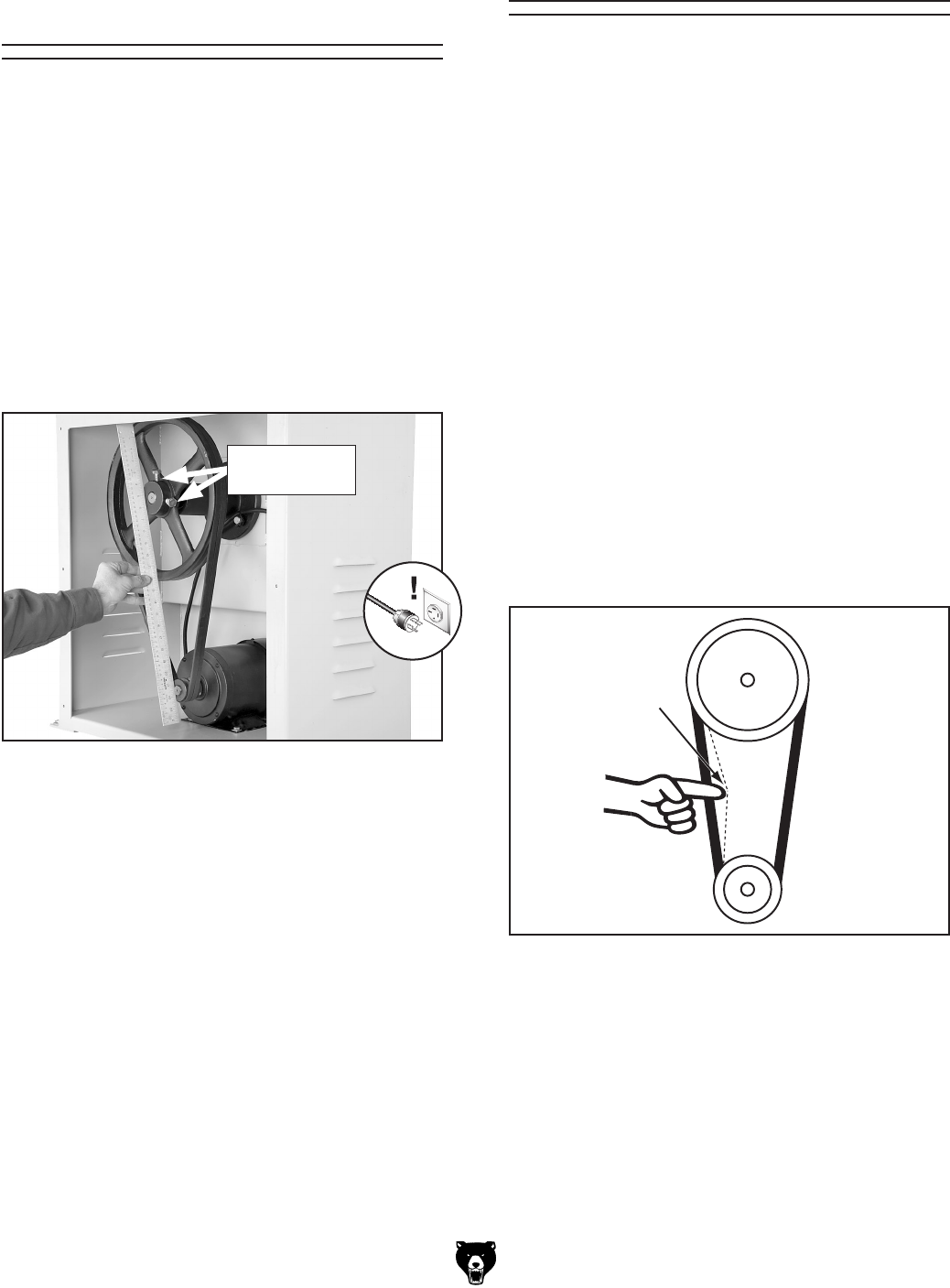

4. Push the center of each V-belt as illustrated

in Figure 42, using moderate force. When

tensioned correctly, the deflection should be

about

3

⁄4".

Figure 42. Checking for correct V-belt tension.

Lower Wheel Pulley

Alignment

Tools Needed: Qty

Hex Wrench 6mm ..............................................

1

Wrench 19mm ...................................................

1

The correct alignment of the motor and lower

wheel pulleys helps to ensure correct and even

tension of the V-belts, proper power transmission,

and reduced V-belt heat and wear during opera

-

tion.

Remove the rear motor access panel, and use

a straightedge across both pulleys, as shown in

Figure 41, to check the pulley alignment.

If necessary, loosen the fasteners securing the

wheel pulley to the shaft, align the wheel pulley

with the motor pulley, then re-tighten the fasteners

for both pulleys.

Figure 41. Checking pulley alignment.

Wheel Pulley

Hex Bolts

pulley alignment

— If the deflection is correct and the V-belts

are in good condition, no further action is

required. Replace the rear motor access

panel.

— If the deflection is more than or less than

3

⁄4" or the V-belts need to be replaced, then

continue with the next steps

.