-33-

G0668 20" Vertical Metal-Cutting Bandsaw

Redressing Rubber

Tires

As the bandsaw ages, the rubber tires on the

wheel may need to be redressed if they become

hardened or glazed over. Redressing the rubber

tires improves blade tracking and reduces vibra

-

tion/blade lead.

If the rubber tires become too worn, then blade

tracking will become extremely difficult. At that

point, redressing will no longer be effective, and

the rubber tires must be replaced.

To redress the rubber tires:

1. DISCONNECT BANDSAW FROM POWER!

2. Put on heavy gloves and remove the blade.

3. Use a brush and shop vacuum to clean any

chips and built-up oil or sludge from the rub

-

ber tires.

4. Hold a piece of 100-grit sandpaper against

the rubber tire and rotate the wheel by hand.

Only redress the rubber enough to expose a

fresh rubber surface.

redressing

Lubrication

The bearings on your bandsaw are factory lubri-

cated and sealed. Merely leave them alone unless

they need to be replaced.

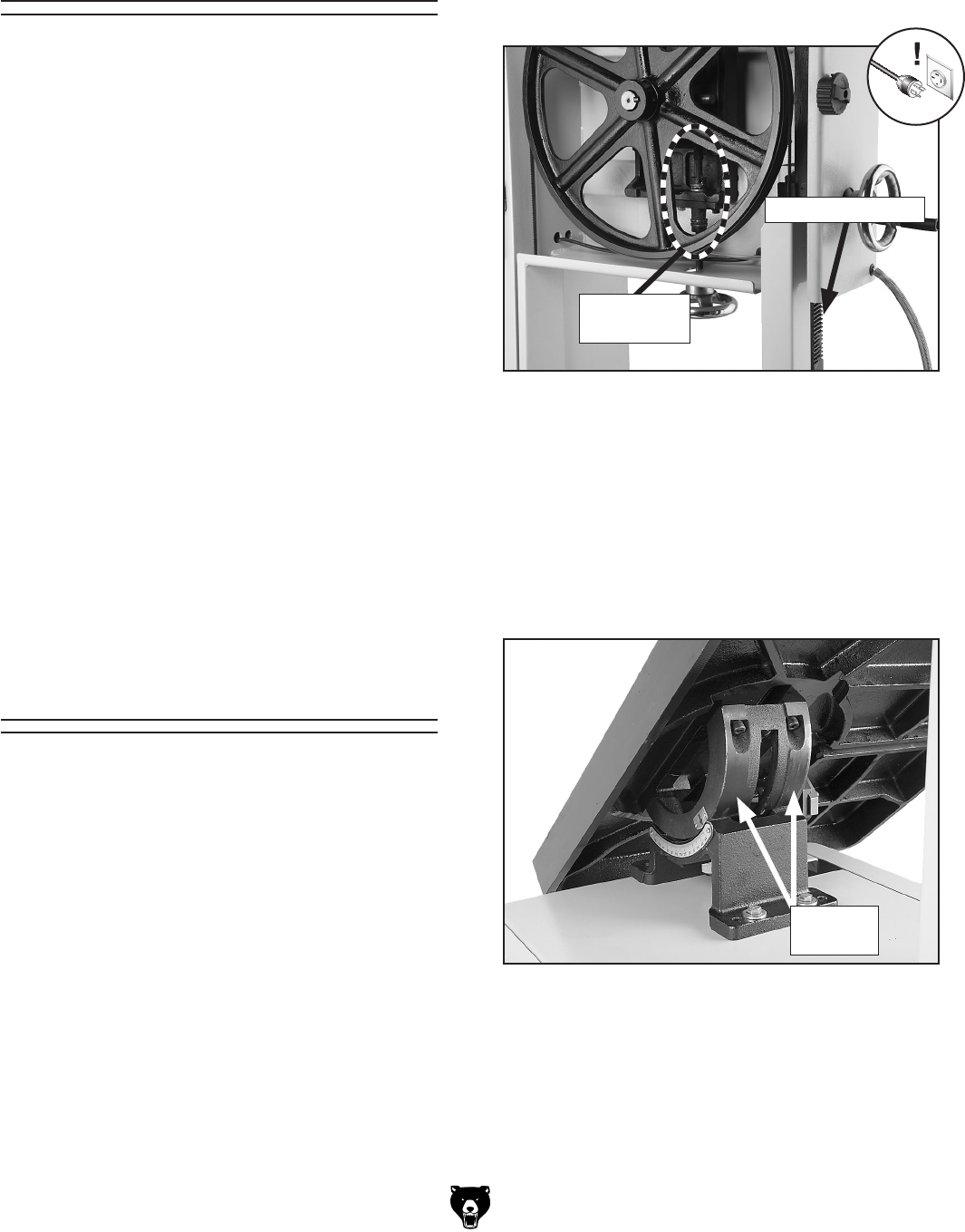

Before lubricating the tension leadscrew or guide

post rack, wipe as much of the old grease off as

possible. The old grease will be contaminated with

metal dust and increase the wear of the metal sur

-

faces. Use mineral spirits or the degreaser shown

in Figure

4 on Page 12 to clean any remaining

grease off, making sure to thoroughly wipe off the

degreaser or mineral spirits that may contaminate

the new grease.

If the table becomes difficult to tilt, position it so

that you use the same process described above

to clean the metal surfaces of the trunnion and

table. Then brush a thin coat of automotive-grade

multi-purpose grease on the trunnion surfaces

(see Figure 40). Tilt the table back and forth to

distribute the grease.

Figure 40. Table tilted to expose trunnion

surfaces.

Trunnion

Surfaces

Figure 39. Tension leadscrew and guide post

rack.

Guide Post Rack

Tension

Leadscrew

When the leadscrew and rack are thoroughly clean

and dry, brush a light coat of automotive-grade

multi-purpose grease on the tension leadscrew

and guide post rack to maintain smooth operation

(see Figure 39).