-14-

Model G0790 (Mfd. Since 9/15)

Bench Mounting

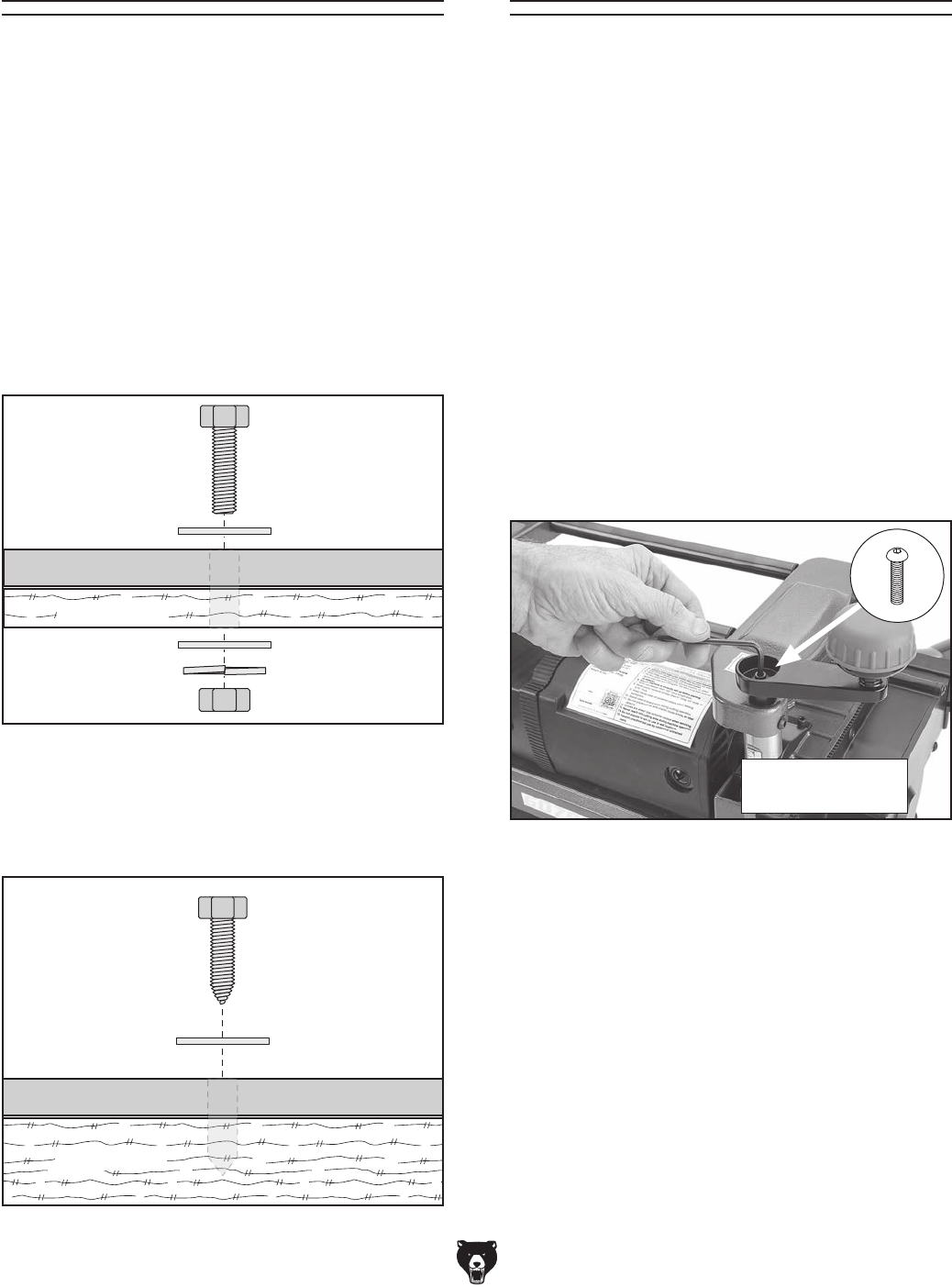

Figure 7. Typical "Direct Mount" setup.

Machine Base

Workbench

Lag Screw

Flat Washer

Another option is a "Direct Mount" (see example

below) where the machine is secured directly to

the workbench with lag screws and washers.

The base of this machine has mounting holes

that allow it to be fastened to a workbench or

other mounting surface to prevent it from moving

during operation and causing accidental injury or

damage.

The strongest mounting option is a "Through

Mount" (see example below) where holes are

drilled all the way through the workbench—and

hex bolts, washers, and hex nuts are used to

secure the machine in place.

Machine Base

Workbench

Hex

Bolt

Flat Washer

Flat Washer

Lock Washer

Hex Nut

Figure 6. Typical "Through Mount" setup.

Number of Mounting Holes ............................ 4

Dia. of Mounting Hardware Needed ..........

5

⁄16"

Assembly

The cutterhead elevation crank, cord wraps, and

dust port must be installed in order to operate the

planer.

To assemble planer loose parts:

1. Assemble cutterhead elevation crank by

snapping knob onto crank handle.

2. Remove black plastic lid from crank handle.

3. Align flat portion inside crank handle bore

with flat portion on elevation shaft, then place

crank assembly on elevation shaft.

4. Thread M5-.8 x 25 button head cap screw

and 5mm flat washer through crank (see

Figure 8) and into shaft. Tighten with 4mm

hex wrench. Do not over-tighten.

5. Re-install black plastic lid.

Figure 8. Installing cutterhead elevation crank.

Cutterhead

Elevation Crank