-28-

Model G0790 (Mfd. Since 9/15)

Machine Operation

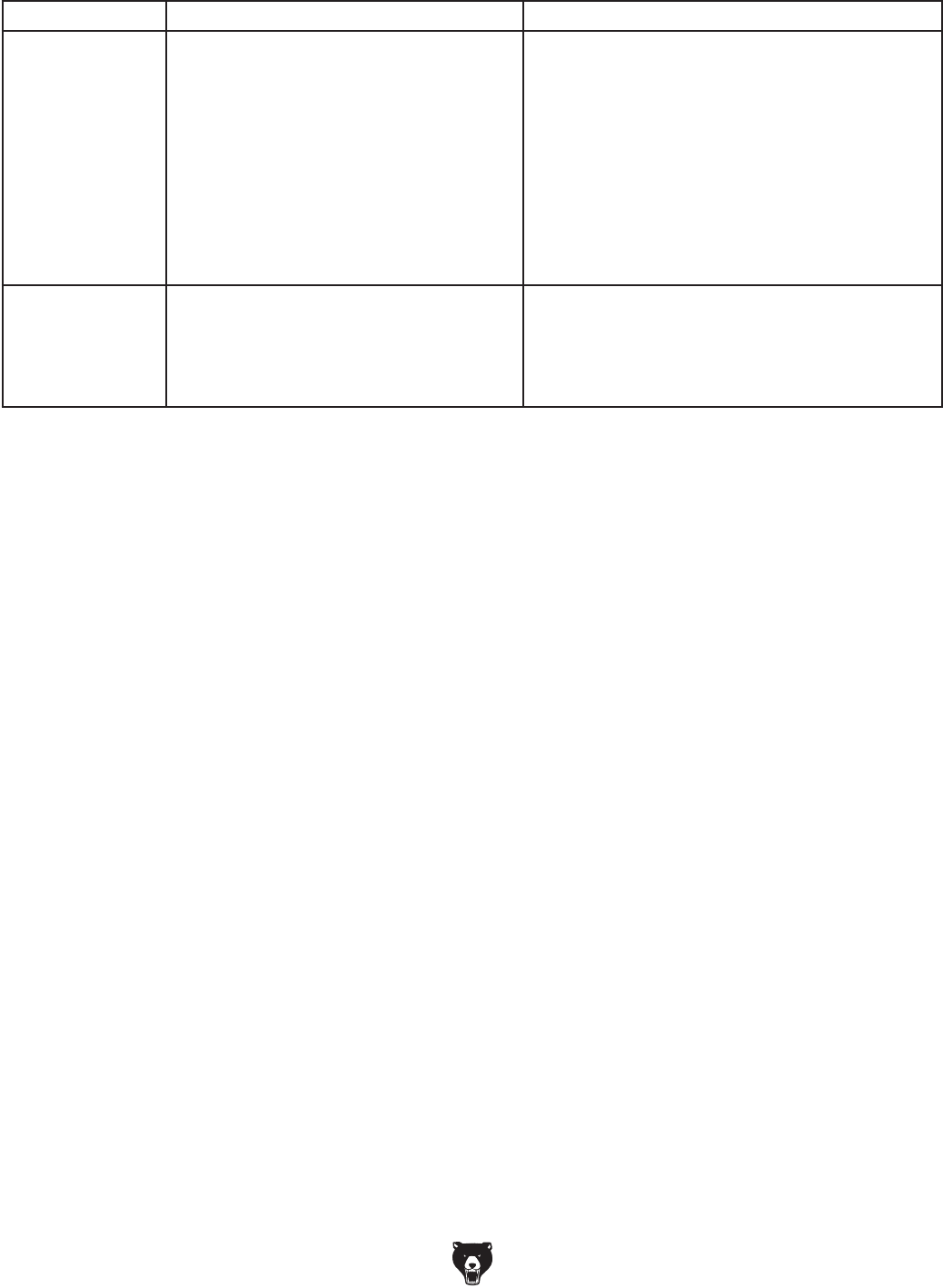

Symptom Possible Cause Possible Solution

Excessive snipe

(gouge at the end of

the workpiece that is

uneven with the rest

of the cut).

Note:

A small

amount of snipe is

inevitable with all

types of planers—

the key is to

minimize it.

1. Aftermarket outfeed support table/rollers

slopes down or is not level with main table.

2. Workpiece not properly supported as it

leaves planer.

1. Adjust rear extension wing set screws to make

extension level with main table.

2. Use an assistant or roller beds/stands to properly

support the workpiece as it leaves the planer.

Consistent chipping

pattern.

1. Knots or conflicting grain direction in

workpiece.

2. Nicked or chipped knife.

3. Feed rate too fast.

4. Depth of cut too deep.

1. Inspect workpiece for knots and grain direction; use

only clean stock (Page 24).

2. Sharpen/replace knife (Page 36).

3. Reduce feed rate (Page 25).

4. Reduce the depth of cut (Page 26).