G1022 Series Contractor Saws -33-

45° and 90° Stops

The Model G1022 Series is equipped with posi-

tive stops at 45° and 90°. When properly adjust-

ed, they provide precise and dependable guides

for bevel adjustment. To set these stops:

1. Unplug the machine! Raise the saw blade

to its maximum height by turning the front

handwheel clockwise.

2. Set the saw blade at 90° to the table by turn-

ing the handwheel at the side of the machine

as far as it will go. Important: Do not force

the handwheels when setting the blade

height or bevel. If the handwheels offer resis-

tance, do not continue turning until you

determine the source of the resistance.

3. Once your blade is set at 90° to the table,

place a machinist's square or speed square

against the blade and table surface, as

shown in Figure 46.

4. With the square in place, inspect for variation

between the blade and square.

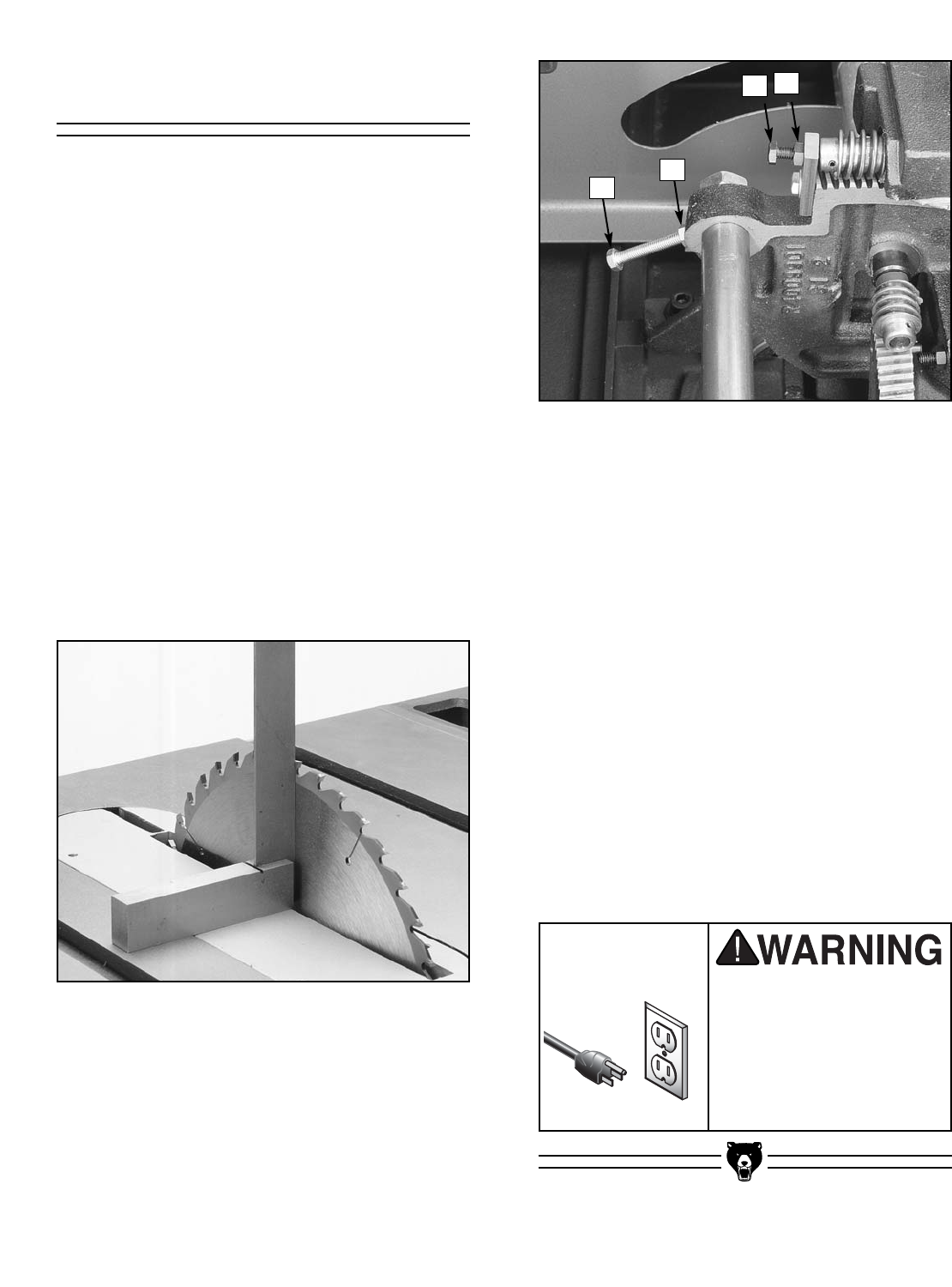

5. If a gap exists at either the top or the bottom

of the square, loosen lock nut (A) and adjust-

ment bolt (B) indicated in Figure 47.

Figure 46. Checking blade angle to table.

6. Turn the handwheel until the blade and

square are flush from top to bottom.

7. Snug the adjustment screw and tighten the

lock nut. Recheck the blade with the square

to ensure that you have not over tightened

the screw.

8. Using the side handwheel, adjust the blade

bevel until you hit the 45° positive stop.

Check the bevel with your speed square or

an adjustable square set to 45°.

9. If variations exist, loosen the lock nut (C) and

adjust the stop bolt (D) (Figure 47) until your

blade and square match.

10. Tighten the lock nut and recheck the bevel

by adjusting the blade back to 90°, then back

to 45°. Correct again, if necessary.

Figure 47. 90° and 45° stop bolt adjustments.

C

D

B

A

Disconnect power to the

machine when perform-

ing any maintenance,

assembly or adjust-

ments. Failure to do this

may result in serious

personal injury.

!