-10-

G1052 9" Bandsaw

Blade Adjustments

Blade tension and tracking are two of the most

important factors affecting bandsaw perfor-

mance. When the blade is properly tensioned and

tracked, blade life will be extended, cuts will be

straighter, and the bandsaw will run more

smoothly. In order to optimize tension and track-

ing, the two wheels must be co-planar (or in the

same plane).

Follow the steps outlined here in the order pre-

sented for best results: (A) adjust tension, (B)

check co-planarity, (C) adjust co-planarity (D)

check tracking, and (E) adjust tracking.

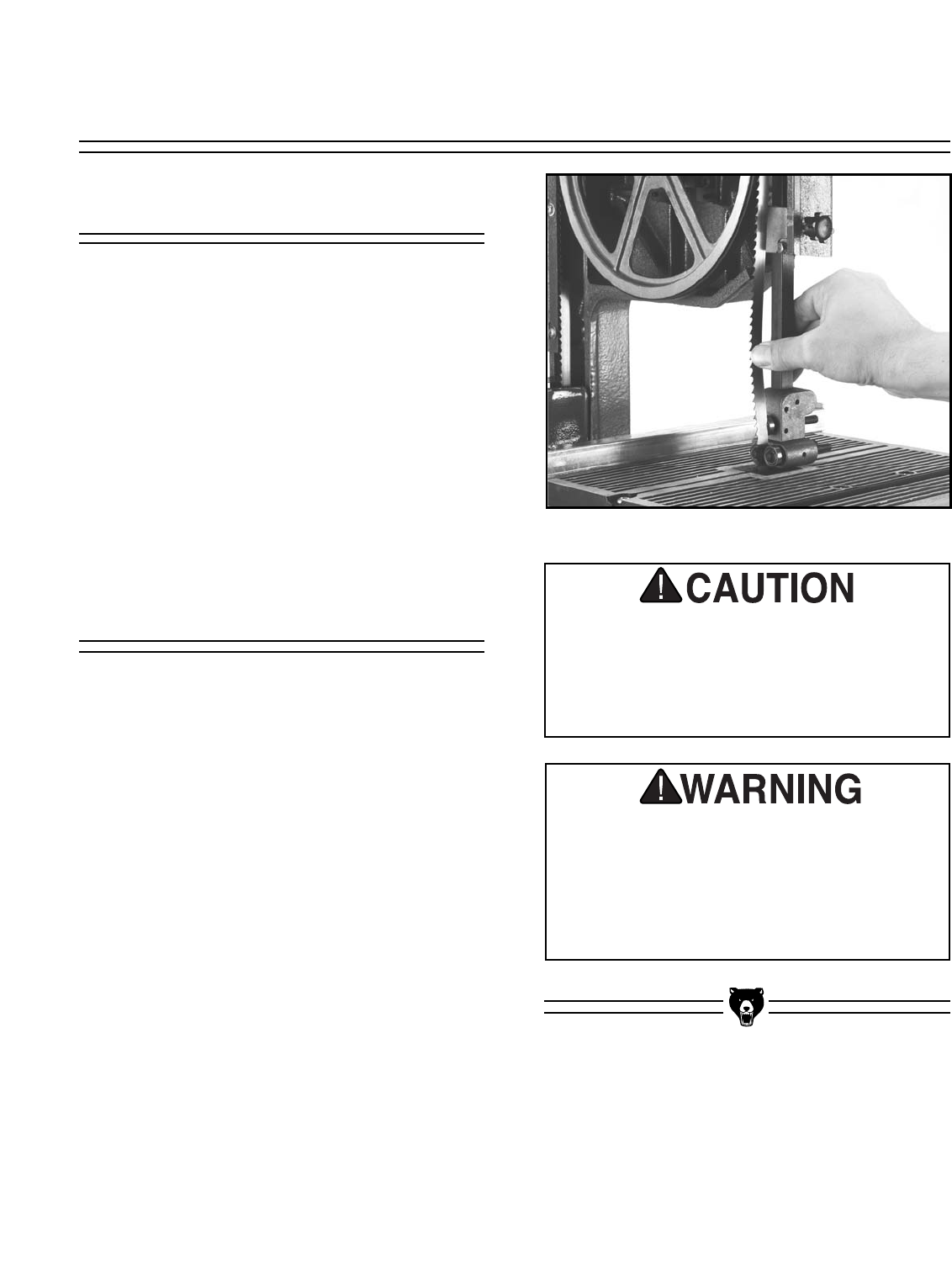

Figure 4. Checking blade deflection.

Blades are extremely sharp. Use added care

when making adjustments that require

touching the blade with your fingers. Failure

to do so could result in serious personal

injury.

Tension

With the exception of those procedures

which require test running the machine, DO

NOT attempt adjustments without ensuring

that the machine is turned off and discon-

nected from its power source. Serious per-

sonal injury may occur.

SECTION 5: ADJUSTMENTS

1. The power must be off with the saw

unplugged. Lower the upper guide assembly

all the way by loosening the guide post

securing knob (#31) and lowering the

assembly.

2. Press, with moderate pressure, on the face

of the blade with your thumb. Figure 4.

3. The blade should flex no more than

1

/2" with

moderate pressure.

4. If it flexes too little or too much, turn the ten-

sion adjustment knob (#2) to modify the ten-

sion until it is correct.

If the tension seems correct, make the other

adjustments to the saw and test run it. Re-adjust

tension if the blade does not cut correctly.