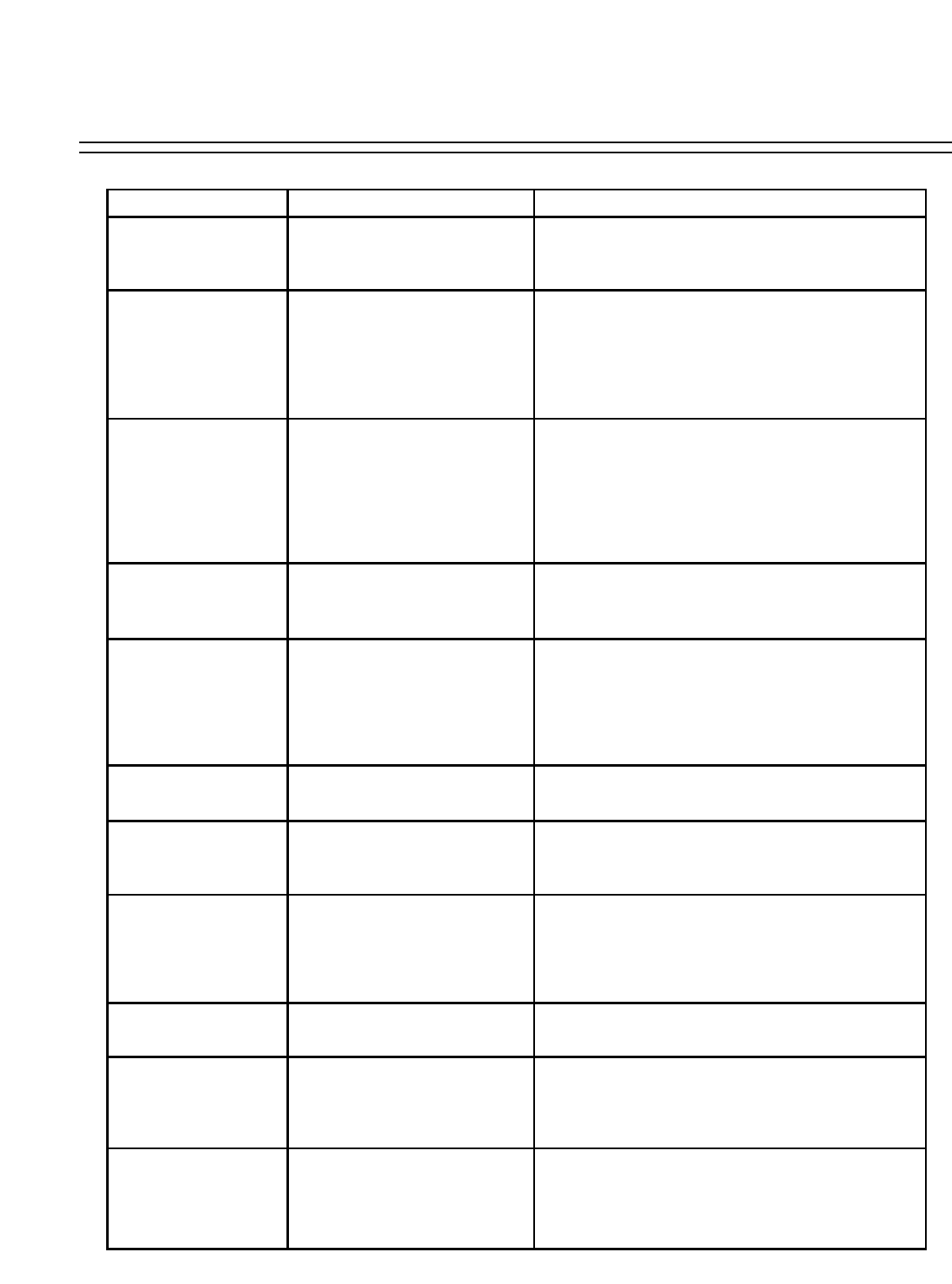

G1052 9" Bandsaw -29-

SYMPTOM

Motor will not start.

Motor will not start; fuses

or circuit breakers blow.

Motor fails to develop full

power (power output of

motor decreases rapidly

with decrease in voltage

at motor terminals).

Motor overheats.

Motor stalls (resulting in

blown fuses or tripped

circuit).

Machine slows when

operating.

Blade does not run even-

ly on wheels or runs off.

Blade does not cut even-

ly

Ticking sound when the

saw is running.

Blade contacting table

insert.

Excessive vibration.

POSSIBLE CAUSE

1. Low voltage.

2. Open circuit in motor or loose

connections.

1. Short circuit in line cord or

plug.

2. Short circuit in motor or loose

connections.

3. Incorrect fuses or circuit

breakers in power line.

1. Power line overloaded with

lights, appliances, and other

motors.

2. Undersized wires or circuits

too long.

3. General overloading of

power company facilities.

1. Motor overloaded.

2. Air circulation through the

motor restricted.

1. Short circuit in motor or loose

connections.

2. Low voltage.

3. Incorrect fuses or circuit

breakers in power line.

4. Motor overloaded.

Applying too much pressure

to workpiece.

1. Tracking is not adjusted

properly.

2. Wheels are not co-planar.

1. Blade tension is incorrect.

2. Tooth set is uneven.

3. Teeth are sharper on one

side than the other.

Blade weld contacting sup-

port bearing.

1. Excessive side pressure

when cutting.

2. Table improperly adjusted.

3. Opening in insert too narrow.

1. Wheels not co-planar.

2. Tires incorrectly installed.

3. Bent or worn out blade.

4. Wheels out of balance.

CORRECTIVE ACTION

1. Check power line for proper voltage.

2. Inspect all lead connections on motor for loose or

open connections.

1. Inspect cord or plug for damaged insulation and

shorted wires.

2. Inspect all connections on motor for loose or short-

ed terminals or worn insulation.

3. Install correct fuses or circuit breakers.

1. Reduce load on power line.

2. Increase wire sizes or reduce length of wire.

3. Request a power check from the power company.

1. Reduce load on motor.

2. Clean out motor to provide normal air circulation.

1. Inspect connections on motor for loose or shorted

terminals or worn insulation.

2 Correct the low voltage conditions.

3. Install correct fuses or circuit breakers.

4. Reduce load on motor.

Feed workpiece slower.

1. Adjust tracking.

2. Adjust wheel co-planarity.

1. Adjust tension.

2. Replace blade, or have it professionally sharp-

ened.

3. Replace blade, or have it professionally sharp-

ened.

Use file or stone to smooth and round the back of

the blade.

1. Reduce side pressure.

2. Adjust table.

3. File the table insert opening larger.

1. Adjust wheels co-planar.

2. Re-install tires.

3. Replace blade.

4. Replace wheels.

TROUBLESHOOTING